200

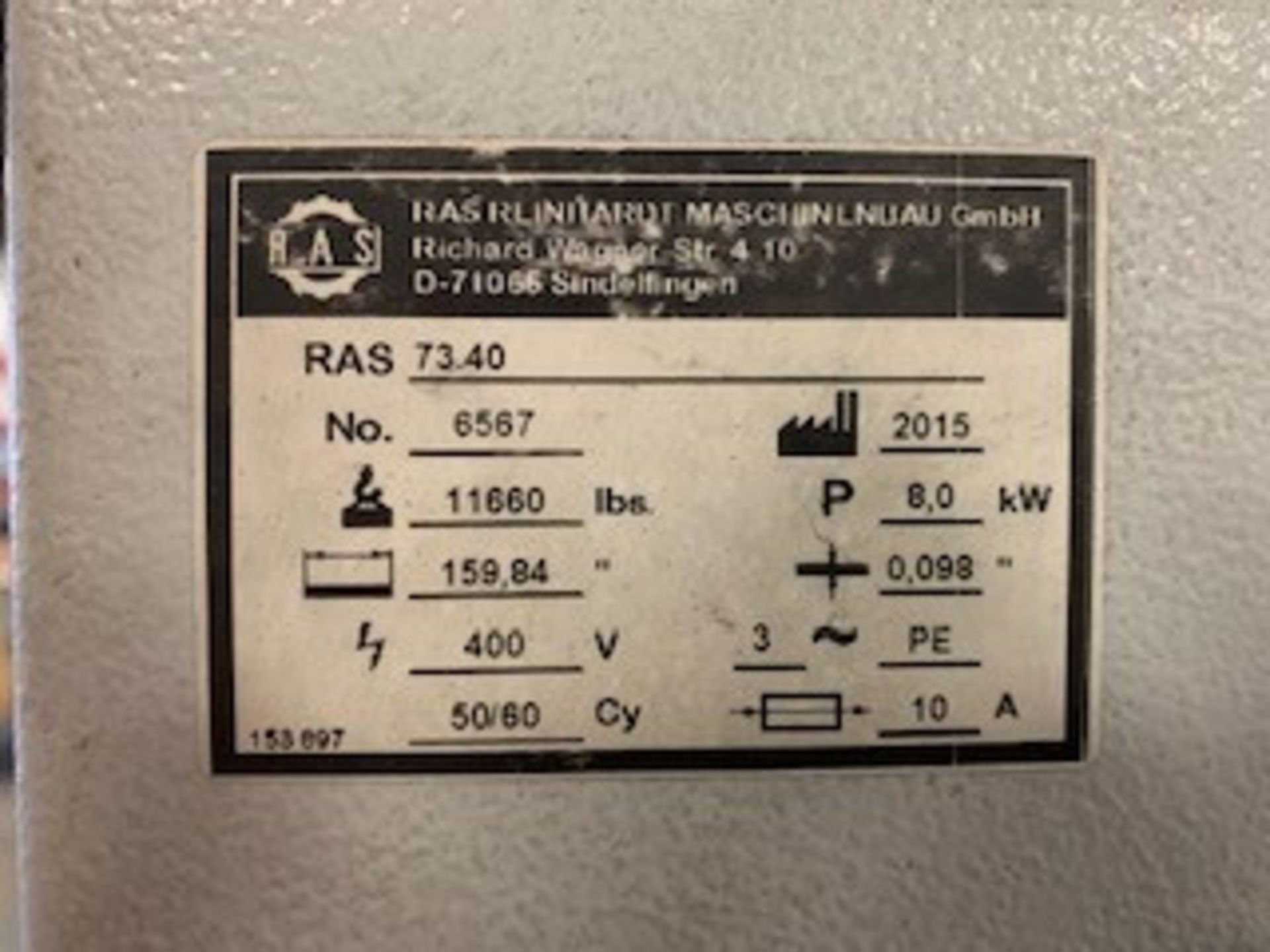

Ras Flexibend 73.40 CNC Folding Machine, S/N 6567, New 2015

Specifications, Flexibility without limits!, The FLEXIbend metal folding system is a study in flexibility. There are almost no limitations to your imagination, when you want to create unique, complex parts with a high level of added value. Flexibility is the key to new products that will help you outperform your competition., Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, FLEXIbend Highlights, Maximum flexibility in bending cassettes, boxes and profiles, High product design flexibility, High productivity and throughput, Easy to operate, Medium investment budget, Shop floor and office programming, Upper beam, The upper beam impresses with large open spaces in front of and behind the beam. The tools are clearly visible to the operator when working on large parts from the rear. As the tool seat automatically clamps the tools, the set-up is done in no time., Fast movements for closing/opening, Hemming: closed, open, tear-drop hems, Large free space in front of the upper beam (part design flexibility), Rigid upper beam for straight bends, Long and deep guiding system (excellent bend results), Housed spindle in a sealed oil bath (low maintenance), Normal and reduced speed (part positioning at marks, Folding beam, The folding beam is the most important component of folding machine. The intelligent crowning system automatically compensates for any folding beam deflection, caused by the bending forces. The FLEXIbend achieves straight bends on thin or thick sheets, all types of material, long or short flanges, bending in the machine center or on the side. The automatic sheet thickness and bend radius adjustment increases productivity and flexibility!, Fast movement: short production time, Deep folding beam: excellent bend results, Automatic adjustment to sheet thickness and bend radius, Clamps the segmented tools automatically, Display shows the folding beam and lower beam position, Simple and error-free machine calibration, Sheet support and gauging system, This combined gauging and sheet support system holds the weight of the panel, positioning it exactly and makes part rotation simple and productive. The stop fingers position the part for each bend. All fingers disappear automatically when the operator wants to rotate the workpiece. For large parts, the rectangular gauging system can be extended to a J- or U-shape table., Working with repeating accuracy, No 2nd operator (50% cost saving), No marking (30% time saving), Supports the weight of the part, Adaptable to job assignment and space conditions, Squaring arm for narrow and long parts, Ball casters in sheet support panels (easy handling), Tooling system, The high-strength and precision-ground upper beam tools are automatically clamped in the tool seat. No other tool system offers so much free space for all imaginable folding geometries. Handy tool segments of maximum make tool setups extremely simple., Large free spaces for flexible part designs, Radius tools and special shapes on request, Short set-up times: handy tools and automatic tool clamping, Individually manufactured precision tools (retrofitable), Folding beam tool widths suitable for thickness and Z-bends, Quick tool changes due to automatic tool clamping, Incline folding beam tool for internal bends (windows, louvers), Segmented lower beam tools for reverse flanges, Finger pockets in lower beam tools for small gauging dimensions, Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, Touch&More control, Use your finger to draw the part with flanges and angles on the screen of the Touch & More control. The software shows the part together with tools and machine components in the later working situation., Control panel on an arm, Drawing of the part with the finger, For most workpieces automatic part programming, Technology tables (angle correction/unfolded length), Program, part and actual bending step are shown at a time, Program library, Operator guidance (text and symbols), Speed Optimizer for 15% less cycle times, Easy Go program for occasional operators, Technical Data, Technical Data FLEXIbend (mm) RAS 73.40 RAS 73.30, Working length 4060 mm 3200 mm, Material thickness max 2.5 mm 3.0 mm, Upper beam upstroke max 300 mm 300 mm, Gauging system (Rectangular gauging system) 10-1550 mm 10-1550 mm, Gauging system (J gauging system) 10-4050 mm 10-3050 mm, Machine dimensions (Rectangular gauging system) 5220 x 2400 mm 4360 x 2360 mm, Machine dimensions (J gauging system) 5220 x 5900 mm 4360 x 3850 mm, Technical Data FLEXIbend (inch) RAS 73.40 RAS 73.30, Working length 159" 126", Material thickness max 13 ga 11 ga, Upper beam upstroke max 11.8" 11.8", Gauging system (Rectangular gauging system) 0.39"-61" 0.39"-61", Gauging system (J gauging system) 0.39"-159" 0.39"-120", Machine dimensions (Rectangular gauging system) 206" x 95" 172" x 93", Machine dimensions (J gauging system) 206" x 193" 172" x 152", Equipped With, CNC CONTOLS, J shape programmable back gauge SYSTEM, Set of standard tools, Extra set of long tools, MACHINE USED FOR ONLY 18 MONTHS ON ONE JOB,

Specifications, Flexibility without limits!, The FLEXIbend metal folding system is a study in flexibility. There are almost no limitations to your imagination, when you want to create unique, complex parts with a high level of added value. Flexibility is the key to new products that will help you outperform your competition., Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, FLEXIbend Highlights, Maximum flexibility in bending cassettes, boxes and profiles, High product design flexibility, High productivity and throughput, Easy to operate, Medium investment budget, Shop floor and office programming, Upper beam, The upper beam impresses with large open spaces in front of and behind the beam. The tools are clearly visible to the operator when working on large parts from the rear. As the tool seat automatically clamps the tools, the set-up is done in no time., Fast movements for closing/opening, Hemming: closed, open, tear-drop hems, Large free space in front of the upper beam (part design flexibility), Rigid upper beam for straight bends, Long and deep guiding system (excellent bend results), Housed spindle in a sealed oil bath (low maintenance), Normal and reduced speed (part positioning at marks, Folding beam, The folding beam is the most important component of folding machine. The intelligent crowning system automatically compensates for any folding beam deflection, caused by the bending forces. The FLEXIbend achieves straight bends on thin or thick sheets, all types of material, long or short flanges, bending in the machine center or on the side. The automatic sheet thickness and bend radius adjustment increases productivity and flexibility!, Fast movement: short production time, Deep folding beam: excellent bend results, Automatic adjustment to sheet thickness and bend radius, Clamps the segmented tools automatically, Display shows the folding beam and lower beam position, Simple and error-free machine calibration, Sheet support and gauging system, This combined gauging and sheet support system holds the weight of the panel, positioning it exactly and makes part rotation simple and productive. The stop fingers position the part for each bend. All fingers disappear automatically when the operator wants to rotate the workpiece. For large parts, the rectangular gauging system can be extended to a J- or U-shape table., Working with repeating accuracy, No 2nd operator (50% cost saving), No marking (30% time saving), Supports the weight of the part, Adaptable to job assignment and space conditions, Squaring arm for narrow and long parts, Ball casters in sheet support panels (easy handling), Tooling system, The high-strength and precision-ground upper beam tools are automatically clamped in the tool seat. No other tool system offers so much free space for all imaginable folding geometries. Handy tool segments of maximum make tool setups extremely simple., Large free spaces for flexible part designs, Radius tools and special shapes on request, Short set-up times: handy tools and automatic tool clamping, Individually manufactured precision tools (retrofitable), Folding beam tool widths suitable for thickness and Z-bends, Quick tool changes due to automatic tool clamping, Incline folding beam tool for internal bends (windows, louvers), Segmented lower beam tools for reverse flanges, Finger pockets in lower beam tools for small gauging dimensions, Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, Metal Folding Machine - Flexibend, Touch&More control, Use your finger to draw the part with flanges and angles on the screen of the Touch & More control. The software shows the part together with tools and machine components in the later working situation., Control panel on an arm, Drawing of the part with the finger, For most workpieces automatic part programming, Technology tables (angle correction/unfolded length), Program, part and actual bending step are shown at a time, Program library, Operator guidance (text and symbols), Speed Optimizer for 15% less cycle times, Easy Go program for occasional operators, Technical Data, Technical Data FLEXIbend (mm) RAS 73.40 RAS 73.30, Working length 4060 mm 3200 mm, Material thickness max 2.5 mm 3.0 mm, Upper beam upstroke max 300 mm 300 mm, Gauging system (Rectangular gauging system) 10-1550 mm 10-1550 mm, Gauging system (J gauging system) 10-4050 mm 10-3050 mm, Machine dimensions (Rectangular gauging system) 5220 x 2400 mm 4360 x 2360 mm, Machine dimensions (J gauging system) 5220 x 5900 mm 4360 x 3850 mm, Technical Data FLEXIbend (inch) RAS 73.40 RAS 73.30, Working length 159" 126", Material thickness max 13 ga 11 ga, Upper beam upstroke max 11.8" 11.8", Gauging system (Rectangular gauging system) 0.39"-61" 0.39"-61", Gauging system (J gauging system) 0.39"-159" 0.39"-120", Machine dimensions (Rectangular gauging system) 206" x 95" 172" x 93", Machine dimensions (J gauging system) 206" x 193" 172" x 152", Equipped With, CNC CONTOLS, J shape programmable back gauge SYSTEM, Set of standard tools, Extra set of long tools, MACHINE USED FOR ONLY 18 MONTHS ON ONE JOB,

VEK Screw Machine Products and CNC High End Machines

Ends from

Venue Address

A rigging fee of $600.00, will be added for blocking and loading on truck.

Important Information

VEK Screw Machine Products and CNC High End Machines - Multiple Locations

Auction Date & Time: lots start closing on Wednesday, December 9th at 9:00 am CT

Inspection: Tuesday, December 8th from 8:00 to 3:00 PM (FOR LOTS 1A TO 149)

Other lots inspection by appointment.

Location: **Assets located at multiple locations.**

18% Buyers Premium applies on all online purchases.

=========================================

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

- IDENTIFICATION: All Participants are required to register prior to becoming an Approved Bidder. All Participants are required to give full name, permanent street address, phone numbers, email address, valid credit card and business name. Subsequent to registration on BidSpotter, approval to bid is at our discretion.

a. DEPOSITS: INTERNATIONAL BUYERS may be asked to submit a refundable deposit.

2. PAYMENT: Invoices must be paid in full by Friday, December 11, 2020. Payment may be made by wire transfer, company check with a bank letter of guarantee, certified funds or cash. (No Credit Cards are accepted) A BUYERS FEE OF 18% WILL BE APPLIED TO INVOICE IN ADDITION TO THE SALES PRICE. Where required by law, ANY APPLICABLE SALES TAX WILL BE APPLIED TO ALL SALES UNLESS BUYER HAS A PROPER EXEMTION. NO MERCHANDISE WILL BE RELEASED UNITIL INVOICE IS PAID IN FULL.

3. Purchase of any lot is at the Purchaser's risk with risk of loss immediately passing to Purchaser upon the auctioneer's call. Neither Premier Asset Recovery Group, LLC, nor its consignors, have any liability of any nature whatsoever to Purchaser if the lot is not delivered to Purchaser due to fire, theft, damage, or any other cause.

4. REMOVAL: All purchases MUST be removed as herein listed. Small items (Tooling, Machine Parts & Accessories, etc.) are to be REMOVED WITHIN 2 DAYS OF THE AUCTION. WE ASSUME NO RESPONSIBILITY FOR SMALL, CARRIABLE ITEMS LEFT ON PREMISES ONE DAY AFTER SALE. All other Machinery & Equipment must be removed by December 18, 2020 items at located in Addison. Other CNC Machines December 31, 2020.

5. Purchases may be removed only on presentation of paid bill. Removal shall be at the expense, risk and liability of the purchaser. Auctioneer shall not be responsible for goods not removed within the time allowed.

6. CONDITION: All Items are sold on “as is – where is”, “in place”, “with all faults” basis no conditions or warranties or representation, written or oral, is given with any lot. All statements contained in Premier Asset Recovery, LLC catalog, website, and marketing material or by the auctioneers, or in any bill of sale, invoice or elsewhere as to description, size, quantity, quality, capacity, model, serial number, measurements or condition, are approximated statements and shall not be deemed to be representations or warranties, oral or written, with respect to any lot. No sale is invalid or made void by reason of any flaw in a lot or by reason of a lot being incorrectly described. Description and Photos are not guaranteed.

It is the buyer’s responsibility to inspect before biding. Premier Asset Recovery Group assumes no liability for error or omissions associated with the auction sale. The buyer does hereby assume and does agree to indemnify and hold the auctioneer and seller harmless from any future claim which shall pertain the fitness or use of the assets being purchased.

7. CLAIMS: NO CLAIMS WILL BE ALLOWED AFTER REMOVAL OF GOODS FROM PREMISES OR LEFT ON PREMISES PAST ALLOWED TIME LIMIT.

8. RESPONSIBILITY FOR NON-DELIVERY: Neither the auctioneer nor the seller, in any event, shall be liable for non-delivery or for any other matter or thing, to any purchaser of any lot, other than for the return to the purchaser of the deposit or sum paid on said lot, should the purchaser be entitled hereto.

9. COMPLIANCE WITH TERMS OF SALE: In default of payment of bills in full within the time therein specified, the auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of resale including legal fees, will be charged to the defaulting purchaser.

10. RISK TO PERSON AND PROPERTY: Persons attending during exhibition, sale or removal of goods assume all risks of damage of or loss to person and property and specifically release the auctioneer and seller from liability therefore. Neither the auctioneer nor his principal shall be liable by reason of any defect in or condition of the premises on which the sale is held.

11. CONTRACT MOVERS: If purchaser wishes to hire or contract with a machinery mover, rigger or other type of outside contractor, PROPER INSURANCE protecting Premier Asset Recovery Group, LLC and the people or company that the auctioneers are conducting the sale for against any or all claims arising from personal injury and/or property damage created by their actions. This requirement is for the auctioneer`s protection - NOT FOR THE PURCHASER`S therefore the auctioneer suggests that the purchaser review the insurance policies of the machinery mover regarding the coverage that they have protecting the purchaser and damage or loss of the equipment they may be moving for the purchaser.

12. ADDITION TO OR WITHDRAWAL FROM SALE: The auctioneer reserves the right to withdraw from sale any of the property listed or to sell at this sale property not listed, and also reserves the right to group one or more lots into one or more selling lots or to subdivide into two or more selling lots. Whenever the best interest of the seller will be served, the auctioneer reserves the right to sell all the property listed, in bulk.

13. It is the Purchaser’s sole responsibility to meet all governmental safety and environmental standards in removing, shipping and using purchased items. Certain of the items for sale may contain “hazardous substances”, as that term is defined under federal, state or local environmental laws and regulations. Premier has no duty to remove any hazardous substances that are contained in or are a part of any items. Purchasers agree to defend (by counsel satisfactory to Premier) and indemnify Premier and hold Premier harmless from any against any claim. Demand, cause of action, liability or expense (including attorney’s fees and costs) asserted against or incurred by Premier in connection with the sale, removal, shipment, or use of any purchased items.

14. DISPUTE BETWEEN BIDDERS: The auctioneer`s decision will be final and absolute.

15. RECORDS: The record of sale kept by the auctioneer and bookkeeper will be taken as final in the event of any dispute.

16. INDEPENDENT CONTRACTOR: The auctioneer is acting as an independent contractor only and is not responsible for the acts of its principals or sellers.

17. ADDITIONAL TERMS AND CONDITIONS: The auctioneer may add other terms and conditions of sale, such additional terms and conditions to be announced prior to the auction.

18. RESERVE: The auctioneer reserves the right to reject any and all bids. On lots upon which there is a reserve, the auctioneer or his assigned agents, shall have the right to bid on behalf of the seller. This Auction Company has requested and been granted access to see all bids placed including any maximum pre-bids. This auction is permitted to engage in this activity by providing this clear disclosure to you, the bidder.

19 These terms and conditions, and all questions with respect to the interpretation of these Terms and Conditions, shall be governed by and construed in accordance with the internal law of the State of Illinois, without regard to conflict of law’s provisions. All bidders expressly consent to personal and exclusive jurisdiction in the courts of the State of Illinois located in Cook County.