09

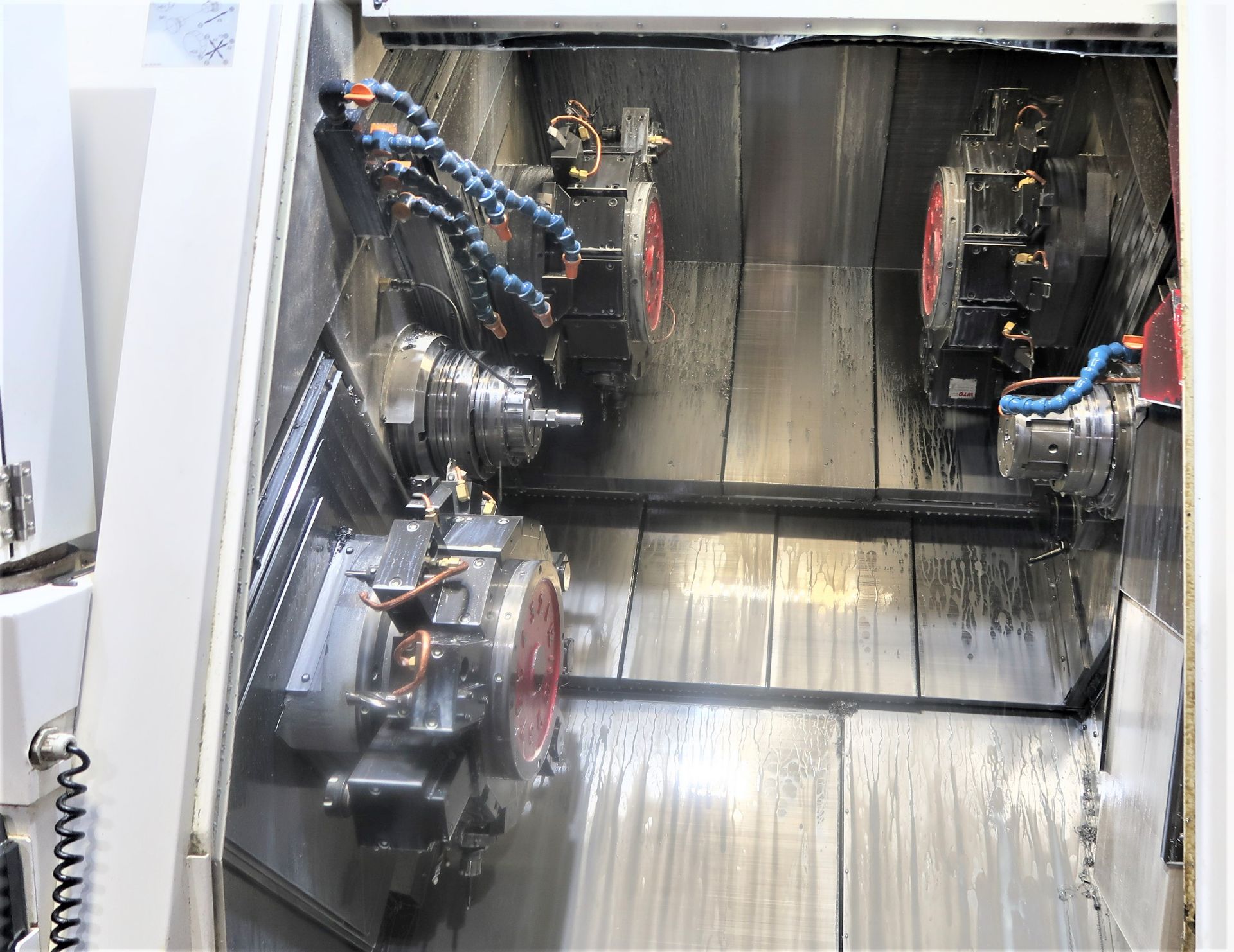

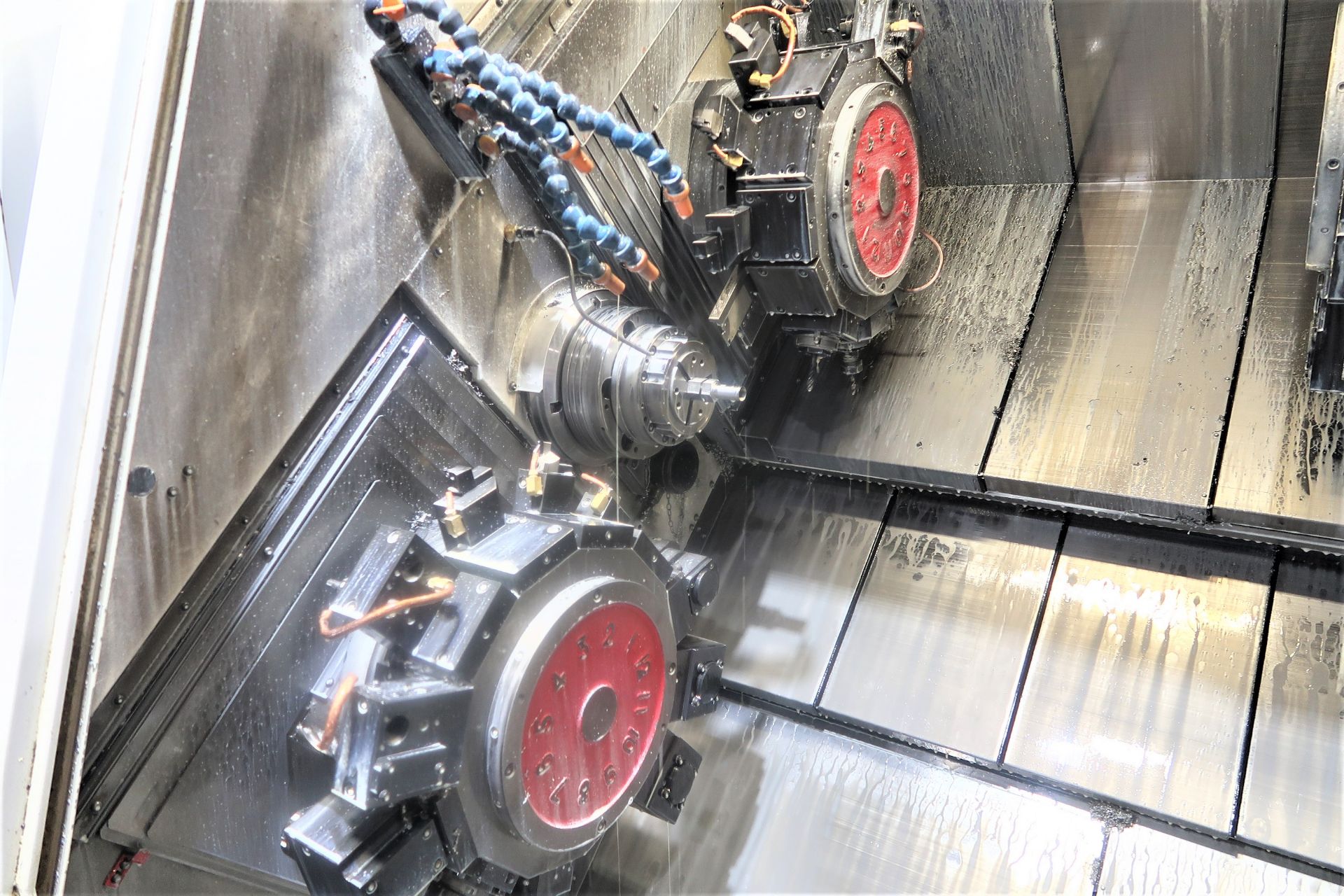

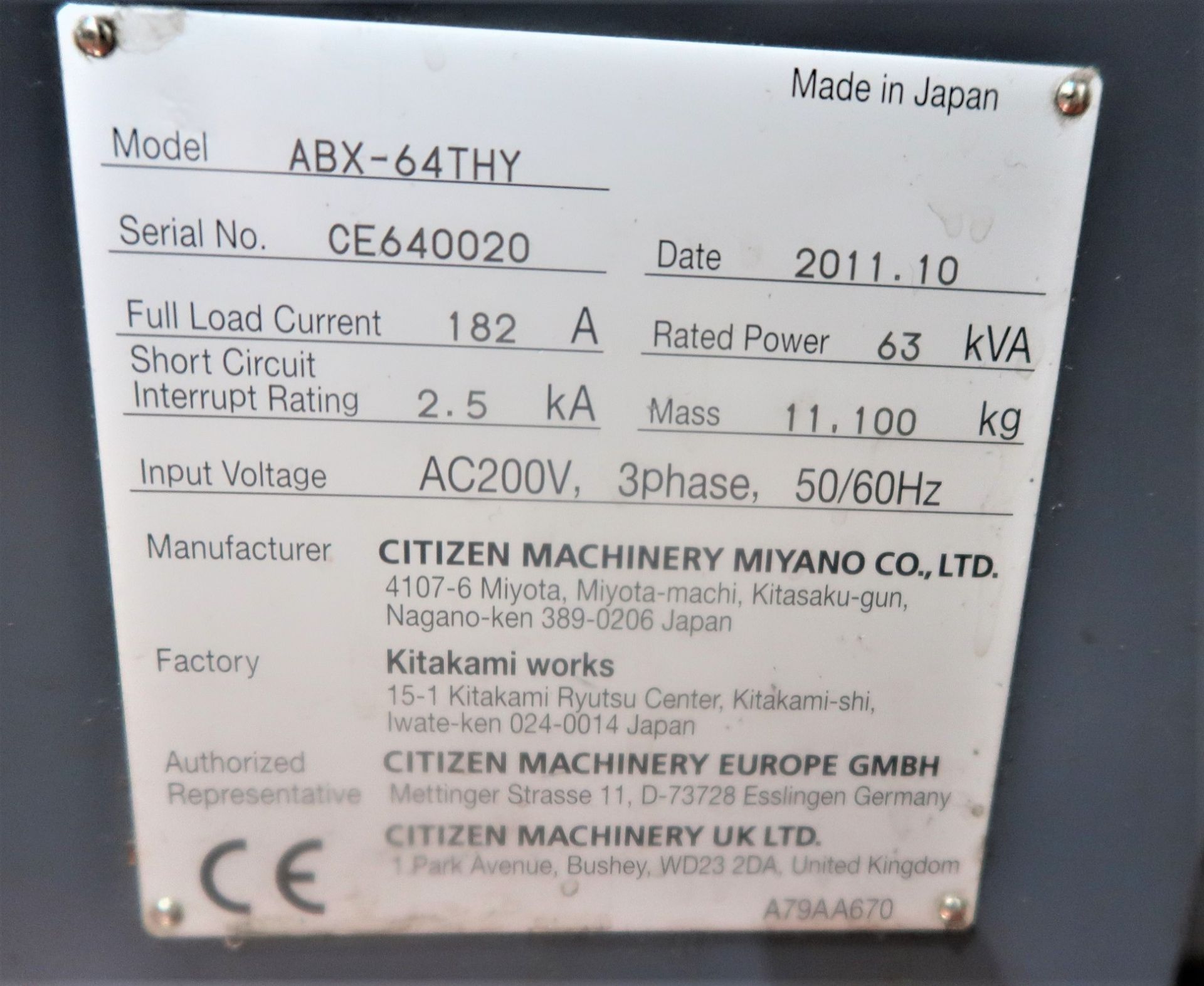

MIYANO MODEL ABX-64THY TWIN SPINDLE TRIPLE TURRET MULTI-AXIS CNC PRECISION TURNING CENTER LATHE 2012

MIYANO MODEL ABX-64THY TWIN SPINDLE TRIPLE TURRET MULTI-AXIS CNC PRECISION TURNING CENTER LATHE

Manufacturer

Miyano

Manufacturing Year

2012

Serial Number CE640020

ModelABX-64THY

Specifications

Machining Capacity:

Standard Turning Length 118mm

Max. Bar Diameter (Main Spindle/Sub Spindle) 64mm/51mm

Max. Power Chuck Size (Main Spindle) 6"

Max. Power Chuck Size (Sub Spindle) 6"

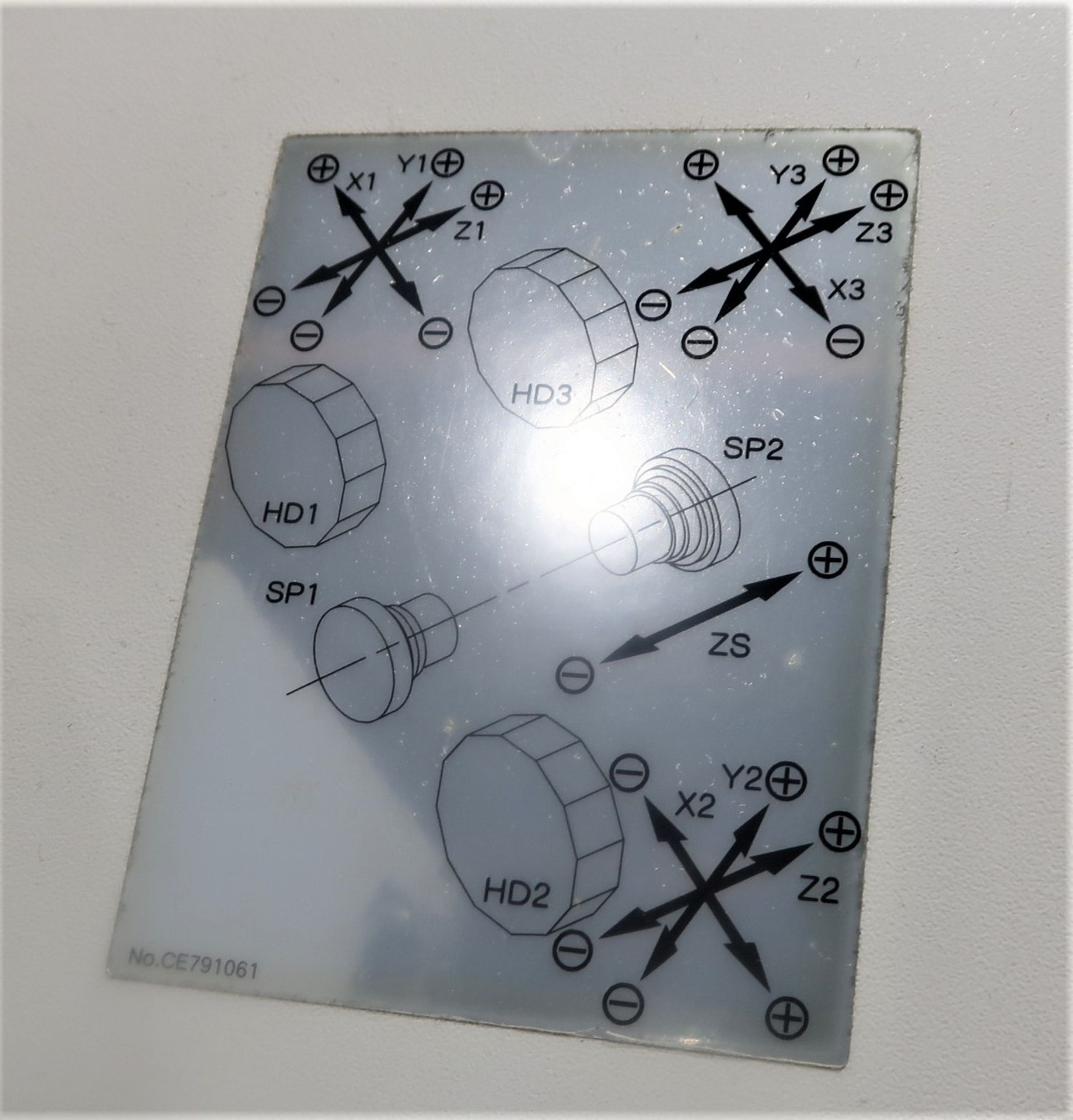

Axis Travel:

HD1-Upper Turret

X1-Axis 190mm

Z1-Axis 257mm

Y1-Axis +/- 40mm

HD2-Lower Turret

X2-Axis 190mm

Z2-Axis 500mm

HD3-Upper Turret

X3-Axis 190mm

Y3-Axis +/- 40mm

Z3-Axis 650mm

Spindles:

Number of Spindles 2

Spindle Speed Range (Main/Sub Spindle) 4000-5000 RPM

Chuck Cylinder; Hydraulic Rotary Hollow Cylinder

Collet Chuck for Left: Spindle (collets not includ) DIN 185E

Collet Chuck for Right Spindle (collets not includ) DIN 177E

Spindle Motors:

Left Spindle: 15/11Kw cont./30 min

Right Spindle: 7.5/5.5Kw

cont./30 min

Turrets:

Number of Turrets 3

Number of Turret Stations:

Upper Turret HD1/HD3 & Lower Turret HD2 12

Main & Sub Spindle Positioning: "C" Axis

(Spindle orientation to both Main & Sub Spindles)

Continue on Page 2

Revolving Tools:

Number of Rotating Tool Stations:

Upper HD1/Upper HD3 12

Lower HD1 12

Speed Range:

Upper HD1/Upper HD3 40-6000 RPM

Lower HD1 40-6000 RPM

Machine weight (approx) 25,000 lbs.

Equipped With

(Standard accessories)

12 Station Upper Turrets HD1 & Hd3 & 12 Station Lower Turret HD2

Fanuc VAC 15 kw/11 kw for Main Spindle & VAC 7.5 kw/5.5 kw for Sub Spindle.

C Axis Control to Main & Sub-Spindles

Y Axis Control to Upper Turret HD1 and Upper Turret HD3

Tool Setter for HD1, HD2 and HD3

Automatic Lubricating System

Coolant System

Hydraulic equipment, Hydraulic Rotary Cylinder for Main & Sub Spindles

Chuck Close/Open Confirmation Switch for Main & Sub Spindle

Splash Guard with Door Interlock System

Machine Light, Pneumatics Unit

Spindle Assembly for DIN 185 E for Main & DN 177E Sub

Inner Coolant, Cylinder-type Work Ejector and Air Blow for Sub Spindle

Servo Driven Parts Catcher for Main & Sub Spindles

Parts Conveyor, High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

Total & Pre-Set Counter, Manual Retrace Function

Filler Tube Assembly, Signal Tower 3-Step,

Double Spindle Orientation

Revolving Tool Drive Unit for Upper & Lower Turrets (HD1, HD2 & HD3)

Cut-off Confirmation - Electrical Type

Cut-off Confirmation - Mechanical Type

Auto Power Shut Off, Coolant Level Switch

Coolant Level Switch

Chip Conveyor-Hinge type for General purpose Usage-Outlet Ht. 1Metre

Disc Brake to both Main & Sub Spindle

Tool Monitoring System (Inc Fanuc N.C. Option and Miyano Software)

Tooling Package: (original package may not be complete)

(12) Turning Tool Holder No. 1 A & (4) Turning Tool Holder No. 1 B

(2) Cut-off Tool Holder No. 1 & (1 Double Turning Tool Holder No. 1 A

(1) Double Turning Tool Holder No. 1 B & (2) Plain Holder (D40mm)

(14) Double Plain Holder (D25mm) & (3) Round Hole Bush - 8mm

(3) Round Hole Bush - 10mm & (3) Round Hole Bush - 12mm

(3) Round Hole Bush - 16mm & (3) Round Hole Bush - 20mm & (2) Sleeve 32

Bar Feed Interface

Fanuc 31i-TA Control:

Constant Surface Speed Control, Multiple Repetitive Cycles

Chamfering/Corner R Compensation, Tool Nose Radius Compensation

Inch/Metric Conversion, Geometry and Wear Offsets

Polar Coordinate Interpolation, Cylindrical Interpolation,

Parts Program Storage Length 320mm, Background Editing

Rigid Tapping Function with Custom macro B for Revolving Tools

Rigid Tapping Function for Main & Sub Spindle, Direct Drawing Dimension input

Extended part Program Editing

Alarm Display, G10 Function, Overlapping Function for HD2, HD3 & Sub Spindle

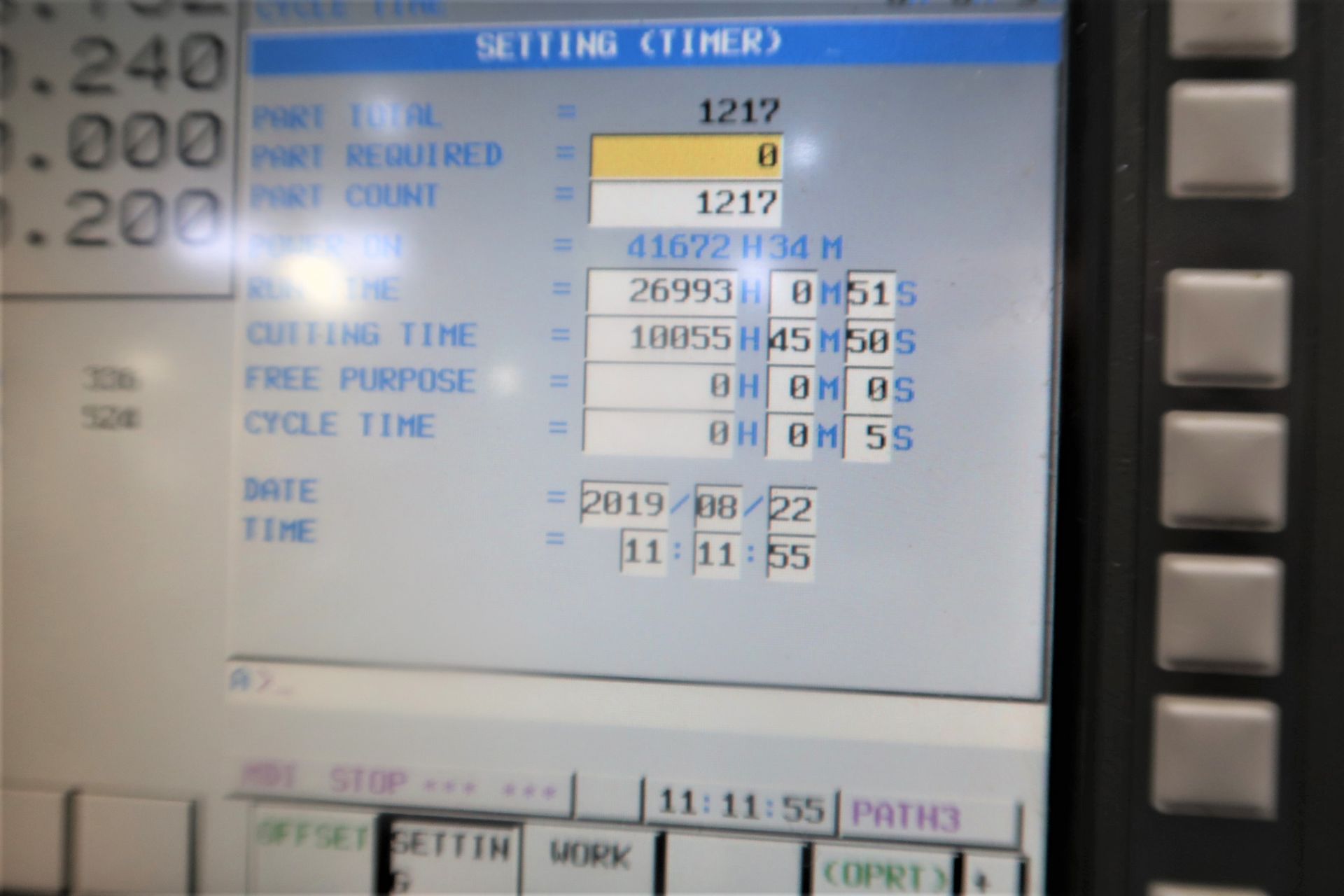

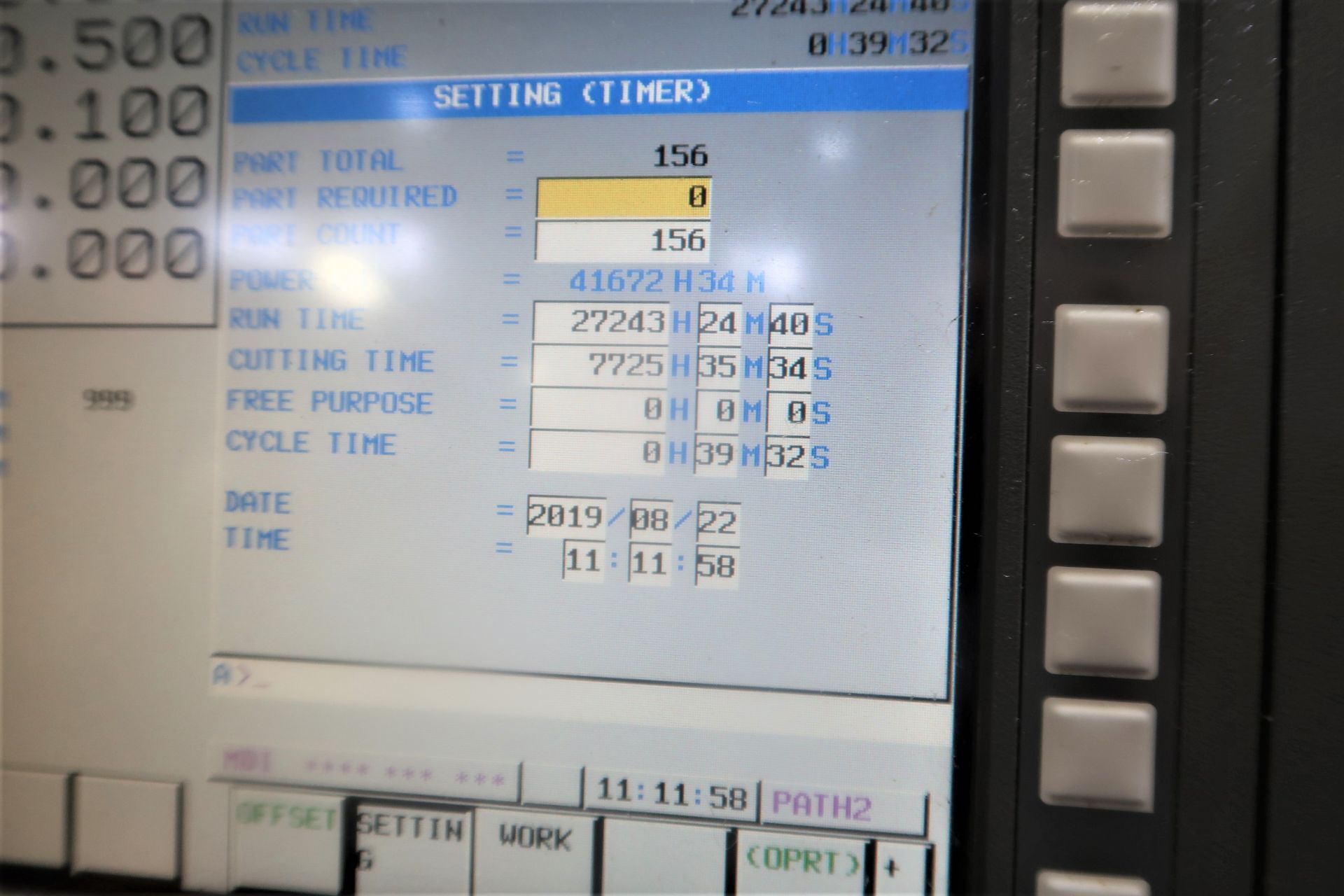

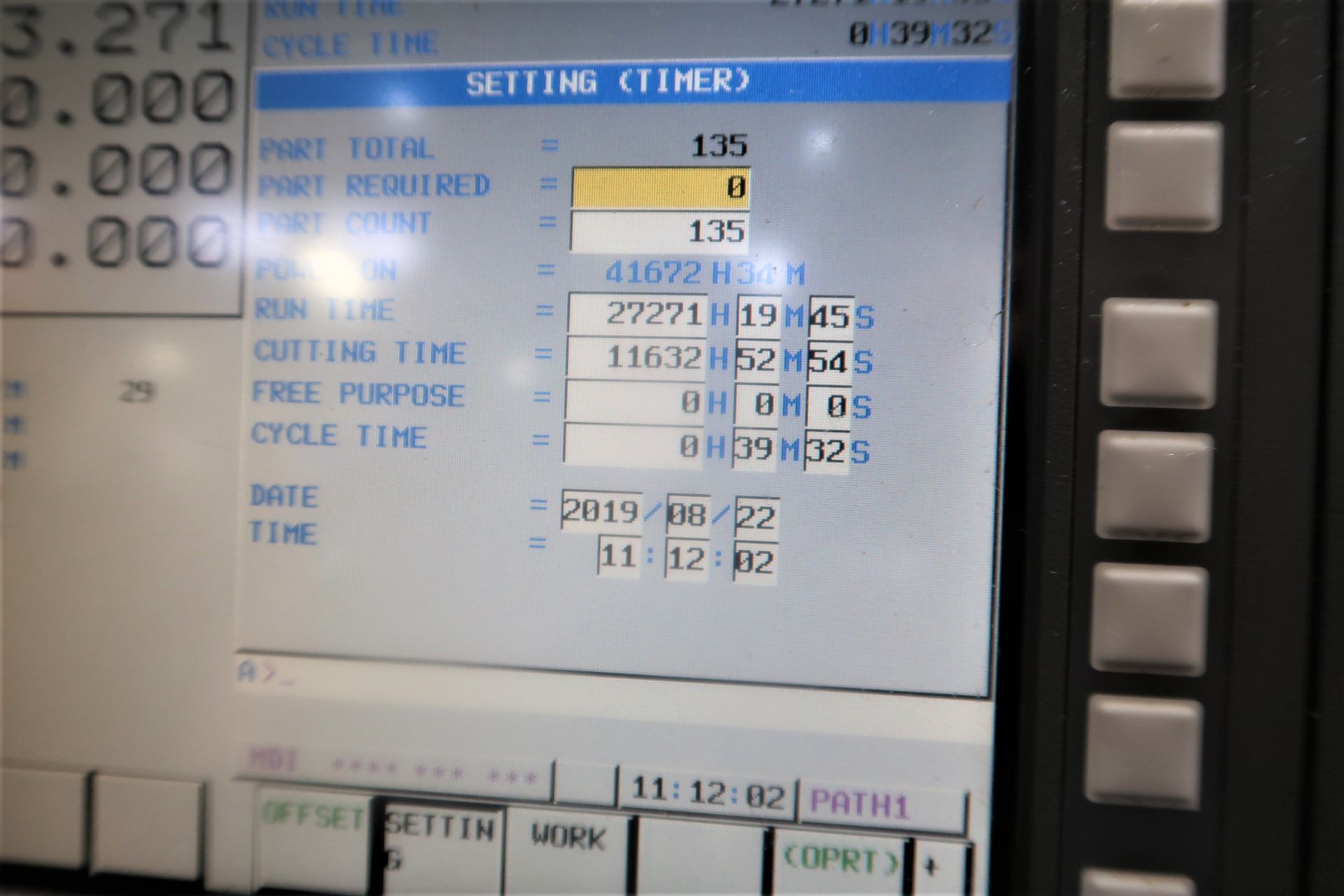

Helical Interpolation, Polygon Turning, Run Hour/Parts Number Counting

Synchronous Mix Control, 500 Sets of Program Counting

Hainbush 2703/0030 Assy for Main Spindle Quick Change 65mm Collet Chuck

Collet Chuck system for Right Spindle DIN177E, X-Spindle Unit - AR25 *3pcs

Z-Spindle Unit - AR25 *1pc, Air Blow for Main & Sub Spindle, Miyano Parting Kit

Integrated Medium pressure 30 bar pressure Coolant pump

LNS Turbo MH500 Chip Conveyor, Bar Feed interface modified to Ar-E1 specs for-LNS

Quick load servo II

CNC Wizard For Miyano

Note: New Replacement Price Exceeds $600,000.00 Today

Run Time 18,000 Hours

64mm CAP,MAIN & SUB SPINDLE,3 TURRETS, 12 STATION LIVE TOOLING (2) C-AXIS, (2) Y-AXIS,5000 RPM,20 HP,FANUC1i-TA, 2012

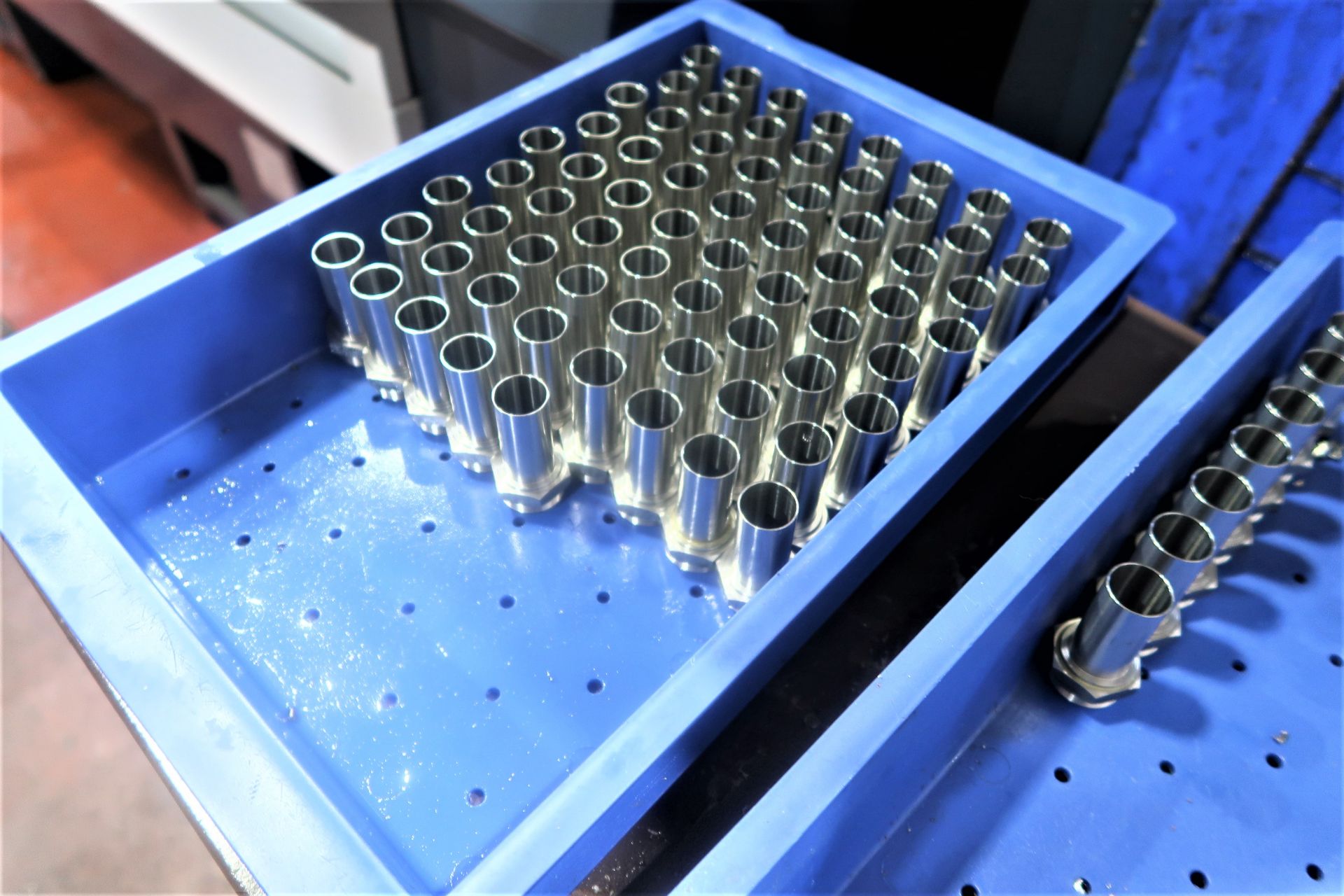

7x Radial drilling and milling head

9x Axial drilling and milling head

APPROX 15k IN SHIPPING COST U.S. PORT

MIYANO MODEL ABX-64THY TWIN SPINDLE TRIPLE TURRET MULTI-AXIS CNC PRECISION TURNING CENTER LATHE

Manufacturer

Miyano

Manufacturing Year

2012

Serial Number CE640020

ModelABX-64THY

Specifications

Machining Capacity:

Standard Turning Length 118mm

Max. Bar Diameter (Main Spindle/Sub Spindle) 64mm/51mm

Max. Power Chuck Size (Main Spindle) 6"

Max. Power Chuck Size (Sub Spindle) 6"

Axis Travel:

HD1-Upper Turret

X1-Axis 190mm

Z1-Axis 257mm

Y1-Axis +/- 40mm

HD2-Lower Turret

X2-Axis 190mm

Z2-Axis 500mm

HD3-Upper Turret

X3-Axis 190mm

Y3-Axis +/- 40mm

Z3-Axis 650mm

Spindles:

Number of Spindles 2

Spindle Speed Range (Main/Sub Spindle) 4000-5000 RPM

Chuck Cylinder; Hydraulic Rotary Hollow Cylinder

Collet Chuck for Left: Spindle (collets not includ) DIN 185E

Collet Chuck for Right Spindle (collets not includ) DIN 177E

Spindle Motors:

Left Spindle: 15/11Kw cont./30 min

Right Spindle: 7.5/5.5Kw

cont./30 min

Turrets:

Number of Turrets 3

Number of Turret Stations:

Upper Turret HD1/HD3 & Lower Turret HD2 12

Main & Sub Spindle Positioning: "C" Axis

(Spindle orientation to both Main & Sub Spindles)

Continue on Page 2

Revolving Tools:

Number of Rotating Tool Stations:

Upper HD1/Upper HD3 12

Lower HD1 12

Speed Range:

Upper HD1/Upper HD3 40-6000 RPM

Lower HD1 40-6000 RPM

Machine weight (approx) 25,000 lbs.

Equipped With

(Standard accessories)

12 Station Upper Turrets HD1 & Hd3 & 12 Station Lower Turret HD2

Fanuc VAC 15 kw/11 kw for Main Spindle & VAC 7.5 kw/5.5 kw for Sub Spindle.

C Axis Control to Main & Sub-Spindles

Y Axis Control to Upper Turret HD1 and Upper Turret HD3

Tool Setter for HD1, HD2 and HD3

Automatic Lubricating System

Coolant System

Hydraulic equipment, Hydraulic Rotary Cylinder for Main & Sub Spindles

Chuck Close/Open Confirmation Switch for Main & Sub Spindle

Splash Guard with Door Interlock System

Machine Light, Pneumatics Unit

Spindle Assembly for DIN 185 E for Main & DN 177E Sub

Inner Coolant, Cylinder-type Work Ejector and Air Blow for Sub Spindle

Servo Driven Parts Catcher for Main & Sub Spindles

Parts Conveyor, High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

Total & Pre-Set Counter, Manual Retrace Function

Filler Tube Assembly, Signal Tower 3-Step,

Double Spindle Orientation

Revolving Tool Drive Unit for Upper & Lower Turrets (HD1, HD2 & HD3)

Cut-off Confirmation - Electrical Type

Cut-off Confirmation - Mechanical Type

Auto Power Shut Off, Coolant Level Switch

Coolant Level Switch

Chip Conveyor-Hinge type for General purpose Usage-Outlet Ht. 1Metre

Disc Brake to both Main & Sub Spindle

Tool Monitoring System (Inc Fanuc N.C. Option and Miyano Software)

Tooling Package: (original package may not be complete)

(12) Turning Tool Holder No. 1 A & (4) Turning Tool Holder No. 1 B

(2) Cut-off Tool Holder No. 1 & (1 Double Turning Tool Holder No. 1 A

(1) Double Turning Tool Holder No. 1 B & (2) Plain Holder (D40mm)

(14) Double Plain Holder (D25mm) & (3) Round Hole Bush - 8mm

(3) Round Hole Bush - 10mm & (3) Round Hole Bush - 12mm

(3) Round Hole Bush - 16mm & (3) Round Hole Bush - 20mm & (2) Sleeve 32

Bar Feed Interface

Fanuc 31i-TA Control:

Constant Surface Speed Control, Multiple Repetitive Cycles

Chamfering/Corner R Compensation, Tool Nose Radius Compensation

Inch/Metric Conversion, Geometry and Wear Offsets

Polar Coordinate Interpolation, Cylindrical Interpolation,

Parts Program Storage Length 320mm, Background Editing

Rigid Tapping Function with Custom macro B for Revolving Tools

Rigid Tapping Function for Main & Sub Spindle, Direct Drawing Dimension input

Extended part Program Editing

Alarm Display, G10 Function, Overlapping Function for HD2, HD3 & Sub Spindle

Helical Interpolation, Polygon Turning, Run Hour/Parts Number Counting

Synchronous Mix Control, 500 Sets of Program Counting

Hainbush 2703/0030 Assy for Main Spindle Quick Change 65mm Collet Chuck

Collet Chuck system for Right Spindle DIN177E, X-Spindle Unit - AR25 *3pcs

Z-Spindle Unit - AR25 *1pc, Air Blow for Main & Sub Spindle, Miyano Parting Kit

Integrated Medium pressure 30 bar pressure Coolant pump

LNS Turbo MH500 Chip Conveyor, Bar Feed interface modified to Ar-E1 specs for-LNS

Quick load servo II

CNC Wizard For Miyano

Note: New Replacement Price Exceeds $600,000.00 Today

Run Time 18,000 Hours

64mm CAP,MAIN & SUB SPINDLE,3 TURRETS, 12 STATION LIVE TOOLING (2) C-AXIS, (2) Y-AXIS,5000 RPM,20 HP,FANUC1i-TA, 2012

7x Radial drilling and milling head

9x Axial drilling and milling head

APPROX 15k IN SHIPPING COST U.S. PORT

CNC EXCHANGE OFFERS 50+ HIGH END CNC Exchange Consignment Sale LIST YOURS TODAY– Multiple Locations

Ends from

Venue Address

For Premier Asset Recovery Group delivery information please telephone 312-280-1234.

Important Information

**This auction has been moved to close on Wednesday, April 8th**

CNC EXCHANGE OFFERS 50+ HIGH END SUPER CNC MACHINE TOOLS AT PUBLIC ONLINE AUCTION SALE, HELIOS, SHUSTER, FEELER, TRAUB, OKUMA, CINCINNATI, MIKRON, SUNFIRM, MILLTRONICS, HWACHEON, MAZAK,VIPER, FADAL, MIYANO, HAAS, TORNOS, TSUGAMI, CITIZEN, STAR, DOOSAN, DAEWOO, VICTOR, FORTUNE, MAKINO, MORI SEIKI, HURCO, TAKAMAZ, EMMEGI, FANUC, KITAMURA, KOMO, ANDERSON,VECTREX, MOLLART, ROTOFINISH, AMERA,SEIKI, MONARCH, WERA, KOEPFER, FELLOWS,MYFORD, SUNNEN, HARDINGE, HEY, ROFIN STARMARK, LEWIS, EDGE, BLANCHARD AND MORE

Online Only Auction

CNC Exchange Consignment Sale – Multiple Locations

Bidding Opens: Wednesday, March 18h at 9:00 AM

Online Bidding Closes: lots start closing on Wednesday, April 8th, at 11:00 am

Location: Assets located at multiple locations.

INSPECTION:

Inspection by appointment, Contact 312-280-1234 ext. 608

Or email Office@premierarg.com

18% Buyers Premium applies on all online purchases.

=========================================

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

1. IDENTIFICATION: All Participants are required to register prior to becoming an Approved Bidder. All Participants are required to give full name, permanent street address, phone numbers, email address, valid credit card and business name. Subsequent to registration on BidSpotter, approval to bid is at our discretion.

2. PAYMENT: Invoices must be paid in full by Friday, April 10, 2020. Payment may be made by wire transfer, company check with a bank letter of guarantee, certified funds or cash. A BUYERS FEE OF 18% WILL BE APPLIED TO INVOICE IN ADDITION TO THE SALES PRICE. Where required by law, ANY APPLICABLE SALES TAX WILL BE APPLIED TO ALL SALES UNLESS BUYER HAS A PROPER EXEMTION. NO MERCHANDISE WILL BE RELEASED UNITIL INVOICE IS PAID IN FULL.

3. Purchase of any lot is at the Purchaser's risk with risk of loss immediately passing to Purchaser upon the auctioneer's call. Neither Premier Asset Recovery Group, LLC, nor its consignors, have any liability of any nature whatsoever to Purchaser if the lot is not delivered to Purchaser due to fire, theft, damage, or any other cause.

4. REMOVAL: All purchases MUST be removed as herein listed. Small items (Tooling, Machine Parts & Accessories, etc.) are to be REMOVED WITHIN 2 DAYS OF THE AUCTION. WE ASSUME NO RESPONSIBILITY FOR SMALL, CARRIABLE ITEMS LEFT ON PREMISES ONE DAY AFTER SALE. All other Machinery & Equipment must be removed by Monday, April 24, 2020.

5. Purchases may be removed only on presentation of paid bill. Removal shall be at the expense, risk and liability of the purchaser. Auctioneer shall not be responsible for goods not removed within the time allowed.

6. CONDITION: All Items are sold on “as is – where is”, “in place”, “with all faults” basis no conditions or warranties or representation, written or oral, is given with any lot. All statements contained in Premier Asset Recovery, LLC catalog, website, and marketing material or by the auctioneers, or in any bill of sale, invoice or elsewhere as to description, size, quantity, quality, capacity, model, serial number, measurements or condition, are approximated statements and shall not be deemed to be representations or warranties, oral or written, with respect to any lot. No sale is invalid or made void by reason of any flaw in a lot or by reason of a lot being incorrectly described. Description and Photos are not guaranteed. Make yourself available e for the Inspection period. It is the buyer’s responsibility to inspect before biding. Premier Asset Recovery Group assumes no liability for error or omissions associated with the auction sale. The buyer does hereby assume and does agree to indemnify and hold the auctioneer and seller harmless from any future claim which shall pertain the fitness or use of the assets being purchased.

7. CLAIMS: NO CLAIMS WILL BE ALLOWED AFTER REMOVAL OF GOODS FROM PREMISES OR LEFT ON PREMISES PAST ALLOWED TIME LIMIT.

8. RESPONSIBILITY FOR NON-DELIVERY: Neither the auctioneer nor the seller, in any event, shall be liable for non-delivery or for any other matter or thing, to any purchaser of any lot, other than for the return to the purchaser of the deposit or sum paid on said lot, should the purchaser be entitled hereto.

9. COMPLIANCE WITH TERMS OF SALE: In default of payment of bills in full within the time therein specified, the auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of resale including legal fees, will be charged to the defaulting purchaser.

10. RISK TO PERSON AND PROPERTY: Persons attending during exhibition, sale or removal of goods assume all risks of damage of or loss to person and property and specifically release the auctioneer and seller from liability therefore. Neither the auctioneer nor his principal shall be liable by reason of any defect in or condition of the premises on which the sale is held.

11. CONTRACT MOVERS: If purchaser wishes to hire or contract with a machinery mover, rigger or other type of outside contractor, PROPER INSURANCE protecting Premier Asset Recovery Group, LLC and the people or company that the auctioneers are conducting the sale for against any or all claims arising from personal injury and/or property damage created by their actions. This requirement is for the auctioneer`s protection - NOT FOR THE PURCHASER`S therefore the auctioneer suggests that the purchaser review the insurance policies of the machinery mover regarding the coverage that they have protecting the purchaser and damage or loss of the equipment they may be moving for the purchaser.

12. ADDITION TO OR WITHDRAWAL FROM SALE: The auctioneer reserves the right to withdraw from sale any of the property listed or to sell at this sale property not listed, and also reserves the right to group one or more lots into one or more selling lots or to subdivide into two or more selling lots. Whenever the best interest of the seller will be served, the auctioneer reserves the right to sell all the property listed, in bulk.

13. It is the Purchaser’s sole responsibility to meet all governmental safety and environmental standards in removing, shipping and using purchased items. Certain of the items for sale may contain “hazardous substances”, as that term is defined under federal, state or local environmental laws and regulations. Premier has no duty to remove any hazardous substances that are contained in or are a part of any items. Purchasers agree to defend (by counsel satisfactory to Premier) and indemnify Premier and hold Premier harmless from any against any claim. Demand, cause of action, liability or expense (including attorney’s fees and costs) asserted against or incurred by Premier in connection with the sale, removal, shipment, or use of any purchased items.

14. DISPUTE BETWEEN BIDDERS: The auctioneer`s decision will be final and absolute.

15. RECORDS: The record of sale kept by the auctioneer and bookkeeper will be taken as final in the event of any dispute.

16. INDEPENDENT CONTRACTOR: The auctioneer is acting as an independent contractor only and is not responsible for the acts of its principals or sellers.

17. ADDITIONAL TERMS AND CONDITIONS: The auctioneer may add other terms and conditions of sale, such additional terms and conditions to be announced prior to the auction.

18. RESERVE: The auctioneer reserves the right to reject any and all bids. On lots upon which there is a reserve, the auctioneer or his assigned agents, shall have the right to bid on behalf of the seller.

19 These terms and conditions, and all questions with respect to the interpretation of these Terms and Conditions, shall be governed by and construed in accordance with the internal law of the State of Illinois, without regard to conflict of law’s provisions. All bidders expressly consent to personal and exclusive jurisdiction in the courts of the State of Illinois located in Cook County.