3

2007 HYUNDAI KIA SKT-15LMS CNC TURNING CENTER WITH SUB SPINDLE, FANUC OI-TB CNC CONTROL, 21” SWING

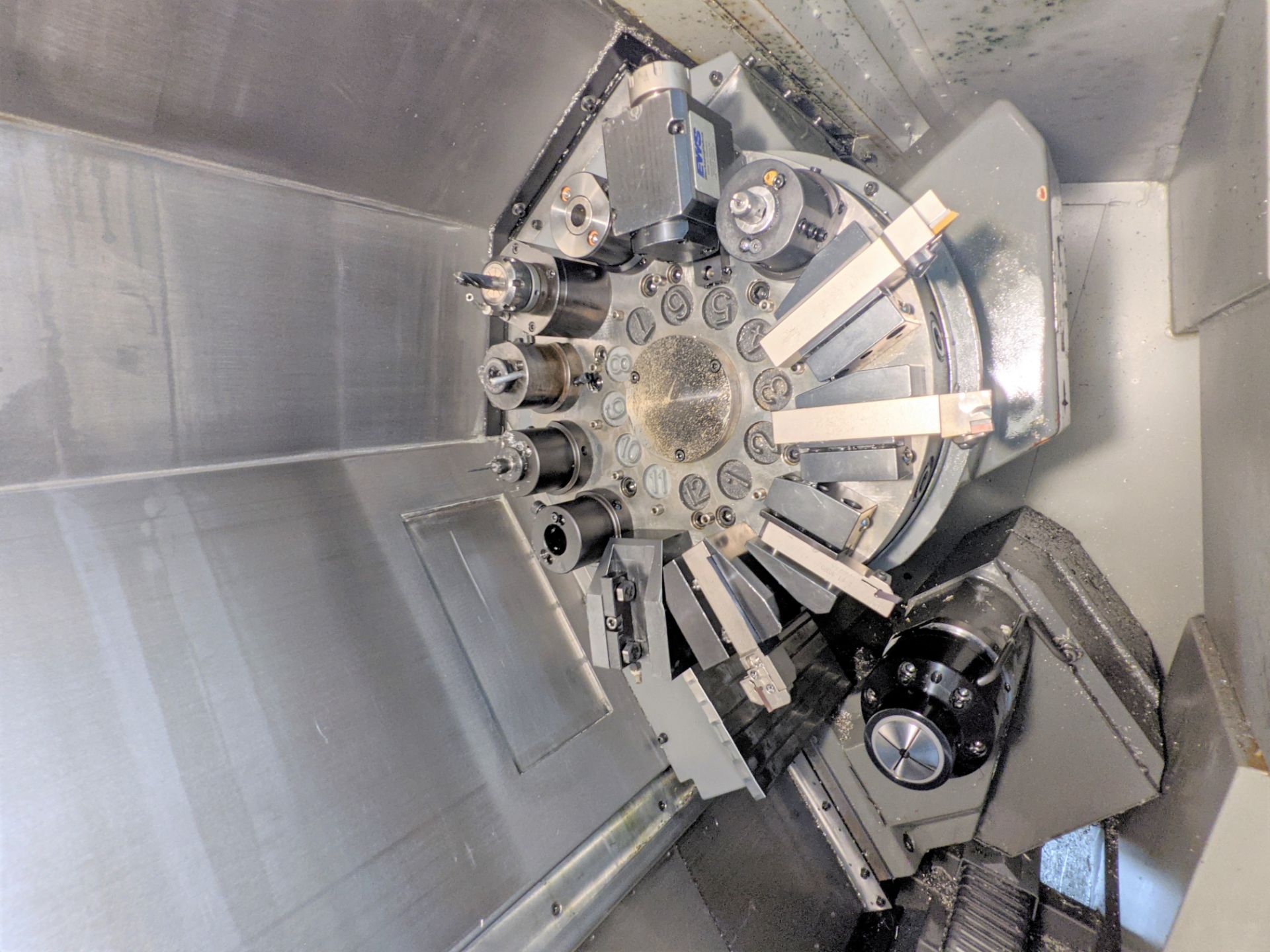

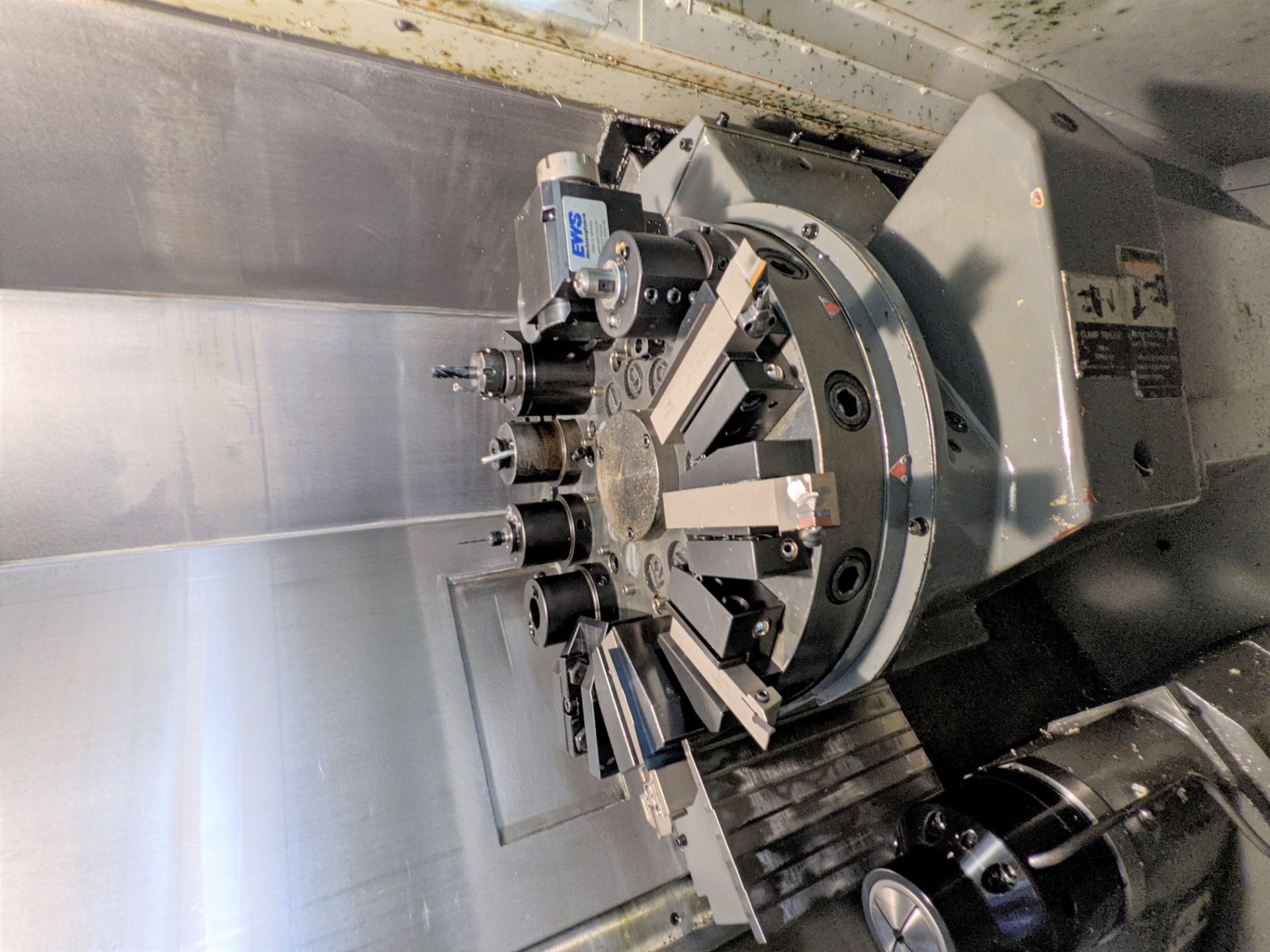

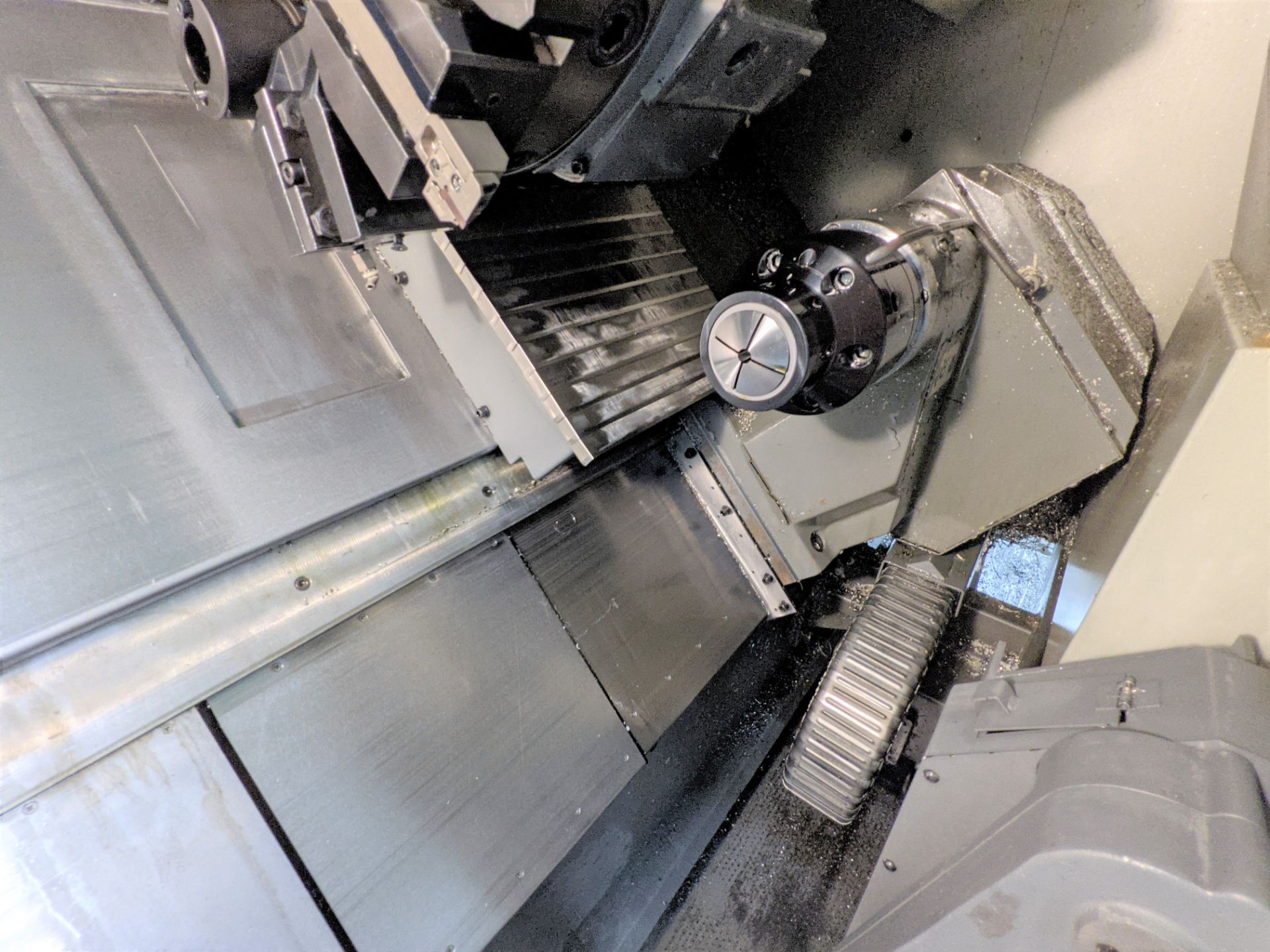

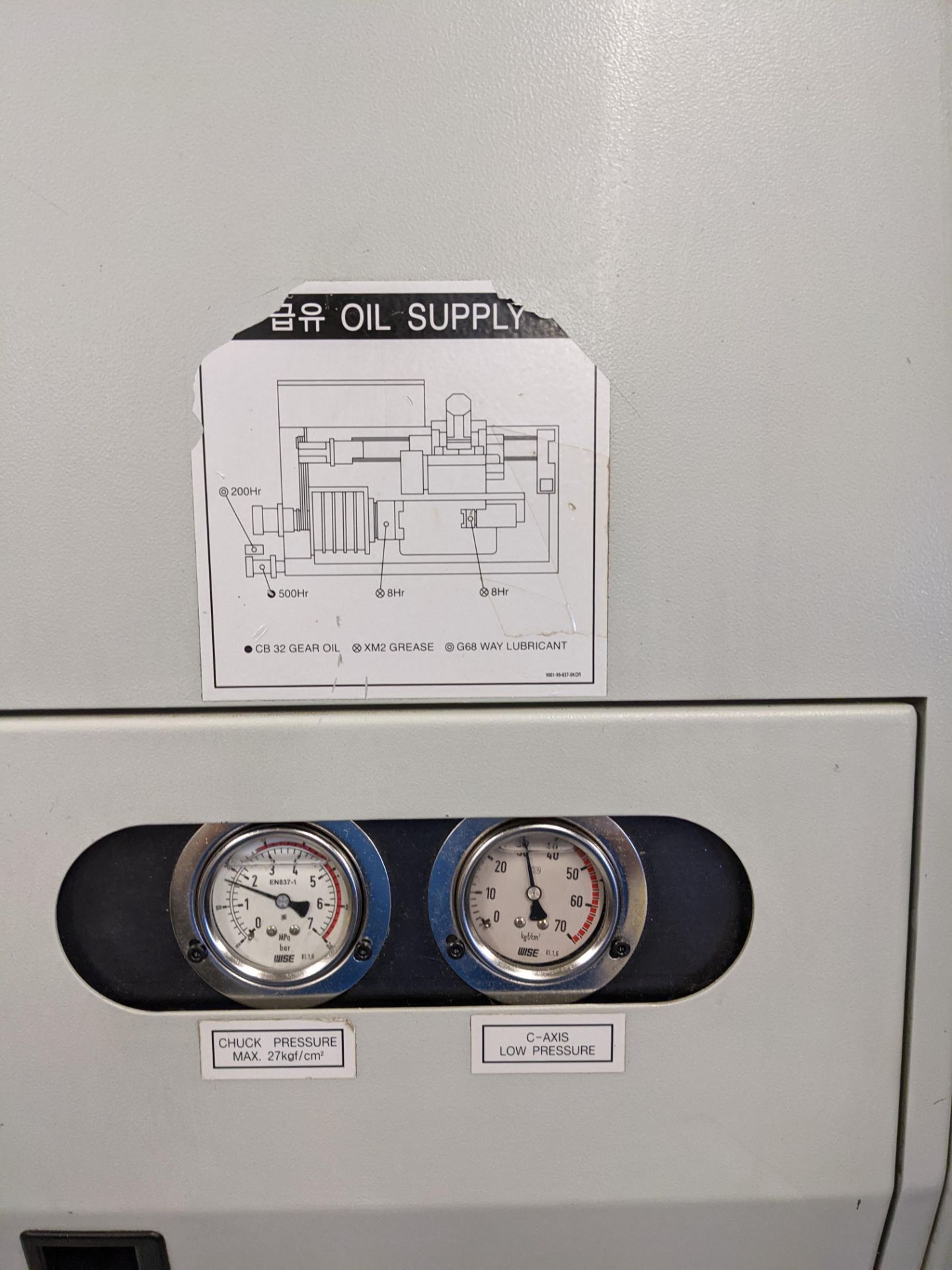

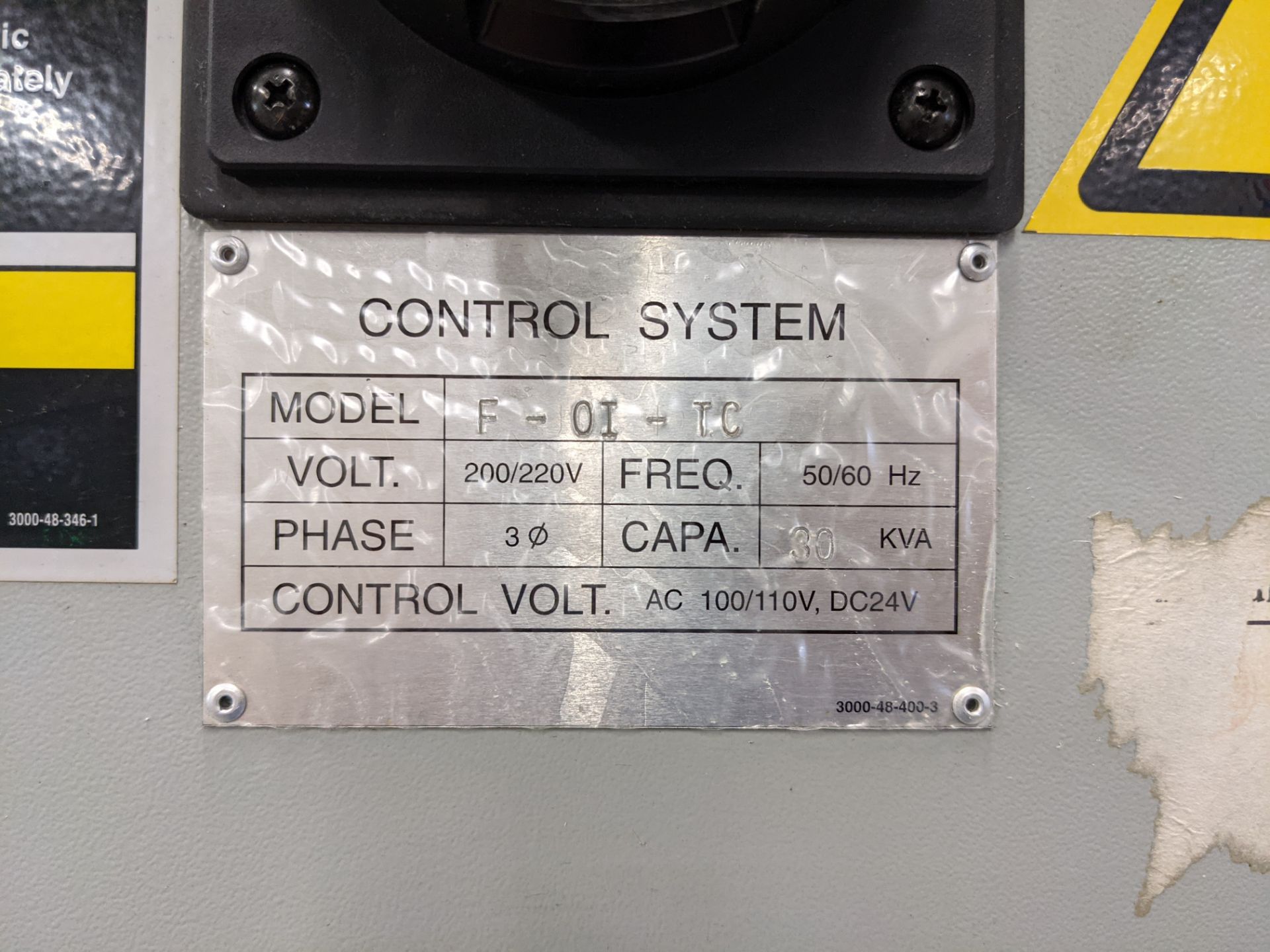

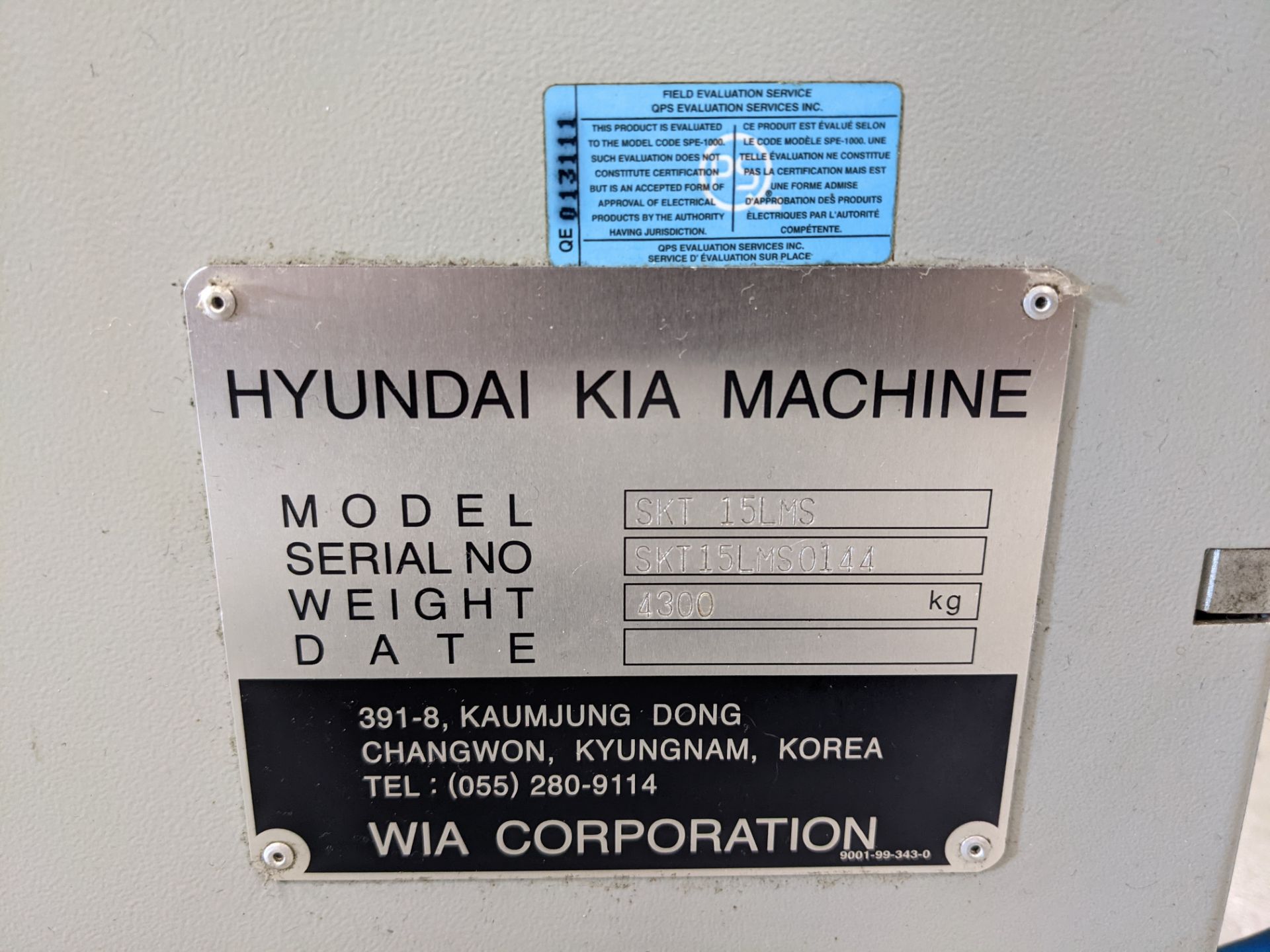

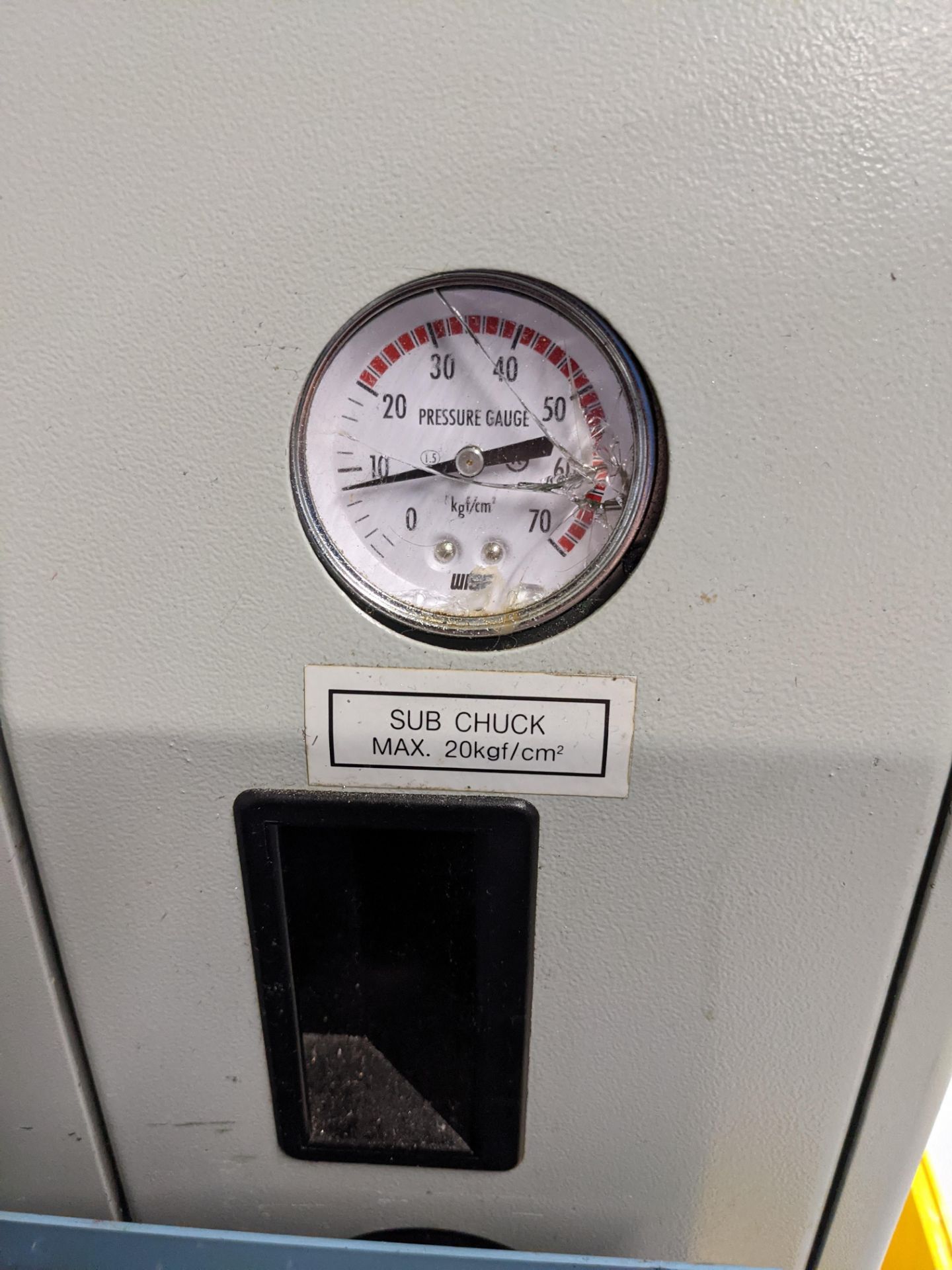

2007 HYUNDAI KIA SKT-15LMS CNC TURNING CENTER WITH SUB SPINDLE, FANUC OI-TB CNC CONTROL, 21” SWING OVER BED, 5,000 RPM MAIN SPINDLE, 6,000 RPM SUB SPINDLE, LIVE TOOLING, COLLET CHUCK, SUB SPINDLE W/ COLLET CHUCK, TOOL PRESETTER, 12-STATION TURRET, 30KVA, 200/220V, 50/60HZ, S/N SKT15LMS0144 APPROX. 7,300 RUN TIME HOURS, INCLUDES ALL LOOSE TOOLING AS SHOWN IN PHOTOS, TOOLING SHOWN IN TURRET IS NOT INCLUDED (MACHINE #5) (RIGGING FEE $1,875 USD)

2007 HYUNDAI KIA SKT-15LMS CNC TURNING CENTER WITH SUB SPINDLE, FANUC OI-TB CNC CONTROL, 21” SWING OVER BED, 5,000 RPM MAIN SPINDLE, 6,000 RPM SUB SPINDLE, LIVE TOOLING, COLLET CHUCK, SUB SPINDLE W/ COLLET CHUCK, TOOL PRESETTER, 12-STATION TURRET, 30KVA, 200/220V, 50/60HZ, S/N SKT15LMS0144 APPROX. 7,300 RUN TIME HOURS, INCLUDES ALL LOOSE TOOLING AS SHOWN IN PHOTOS, TOOLING SHOWN IN TURRET IS NOT INCLUDED (MACHINE #5) (RIGGING FEE $1,875 USD)

Battlefield International Inc. - Surplus to the Ongoing Operations

Ends from

Venue Address

THE EXCLUSIVE RIGGER FOR THIS AUCTION:

National Rigging and Transportation

100 Municipal Street

Welland, Ontario

Canada L3B 3P2

Attn: Darren Chapman

Office: 1-905-788-1110

Mobile: 1-905-704-9011

darren@nationalrigging.com

Important Information

Auction Date & Time: lots start closing on Thursday, October 14th at 11:00 am ET

Location: 1664 Kohler Rd, Cayuga, Ontario

Inspection: By Appointment Only

18% Buyers Premium applies on all online purchases.

Featuring:

2014 HYUNDAI WIA L400LMC BIG BORE Multi-Axis CNC Turning Center with FANUC 32i-A CNC Control, 18” 3-Jaw Chuck, Big Bore Option with 6.52” Bar Cap., 82.5” Max. Turning Length, 28.5” Max. Turning Dia., 2,000 RPM 50HP Spindle Motor, Tailstock, Tool Presetter, 12-Station Live Tool Turret (2 Axial and 2 Radial Live with 4,000 RPM), Chip Conveyor, 46KVA, 220V, 60Hz, NOTE: INSTALLED NEW in 2017, Approx. 3,300 Runtime hrs., s/n G3199-0113 (MACHINE #16)

2013 HYUNDAI WIA LS2100SY CNC Turning Center with Sub Spindle, FANUC 31i-A CNC Control, 24.8” Swing Over Bed, 4,500 RPM Main Spindle w/ Collet Chuck, 6,000 RPM Sub Spindle with 6” 3-Jaw Chuck, 5,000 RPM Live Tooling, Tool Presetter, 12-Station Turret, Parts Catcher, Chip Conveyor, 220V, 60Hz, 33KVA, Approx. 7,200 Runtime hrs. s/n G3184-0062 (MACHINE #3)

2007 HYUNDAI KIA SKT-15LMS CNC Turning Center with Sub Spindle, FANUC Oi-TB CNC Control, 21” Swing Over Bed, 5,000 RPM Main Spindle, 6,000 RPM Sub Spindle, Live Tooling, Collet Chuck, Sub Spindle w/ Collet Chuck, Tool Presetter, 12-Station Turret, 30KVA, 200/220V, 50/60Hz, s/n SKT15LMS0144 Approx. 7,300 Run Time Hours (MACHINE #5)

2006 HYUNDAI KIA SKT210Y CNC Turning Center with FANUC 2Ti-TB CNC Control, 20” Swing Over Bed, 4,000 RPM Main Spindle, 6,000 RPM Sub Spindle, Collet Chuck, Tailstock, Tool Presetter, Parts Catcher, 12-Station Turret, Live Tooling, LNS Turbo Hinge Belt Chip Conveyor, 21KVA, 200/220V, 50/60Hz, s/n SKT210Y0007 w/ 2006 SAMSYS+ MUS3000 Bar Feeder, s/n 06160, Approx. 9,800 Run Time Hours, s/n SKT210Y0007 (MACHINE #4)

2006 HYUNDAI KIA SKT-15 CNC Turning Center with FANUC Oi-TC CNC Control, 21.6” Swing Over Bed, 5,000 RPM Spindle, Collet Chuck, Tailstock, Tool Presetter, Parts Catcher, 12-Station Turret, Live Tooling, 20KVA, 200/220V, 50/60Hz, Approx. 7,500 Run Time Hours, s/n SKT151190 (MACHINE #15)

2004 HYUNDAI KIA SKT-15LMS CNC Turning Center with Sub Spindle, FANUC Oi-TB CNC Control, 21.6” Swing Over Bed, 5,000 RPM Main Spindle, 6,000 RPM Sub-Spindle, 4,000 RPM Live Tooling, Tool Presetter, 12-Station Turret, Collet Chuck, 3-Jaw Chuck, 30KVA, 200/220V, 50/60Hz, Approx. 7,400 Run Time Hours, s/n SKT15LMS069 (MACHINE #1)

2006 FADAL VMC2216FX CNC Vertical Machining Center with FADAL GE FANUC Oi-MC CNC Control, 16” x 39” Table, Travels: X-22”, Y-16”, Z-20”, CAT 40, 8,000 RPM, 15HP, (21) ATC, 16KVA, 240VAC, 50/60Hz, Approx. 3,202 Run Time Hours s/n 012006089132 (MACHINE #10)

2010 TROTEC FP100-20 Speedy 100 Fiber Laser Engraver, FP100/20, 20Watts, Input Power: 115VAC, 10A, 50/60Hz, Working Area: 24” x 12”, Maximum Height of Workpiece: 4.92”, Maximum Engraving Speed: 78.75 inch/second, s/n F1-0221

MENTOR DYNAMICS 20-Ton Cap. Free Standing Bridge Crane System, 40’ Span x 173’ Runway, Hook Travels: 28’W x 160’L x 14’H, Speeds: Crane 100 FPM, Trolley 50 FPM, Hoist 14 FPM, Pendant Control, All Support Columns, Rails, Runway, Busbar, 575/3/60 Power Supply, s/n 1288, Currently Installed in 21’ Clearance Height, Installed 2016, Drawings Available (LOCATED IN ST. THOMAS, ON)

=========================================

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Friday, 8:00 AM EST – 8:00 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

PAYMENT: NO PAYMENTS WILL BE ACCEPTED ON SITE. All payments must be in either Cash, Certified Cheque, Wire Transfers or Company Checks must be accompanied with a bank letter guaranteeing irrevocable payment to Infinity Asset Solutions Inc., Visa & Mastercard will be accepted for total payments of $2,000.00 or less (amounts more than $2,000.00 will be subject to a 3% administrative fee).

Payment is due by: 2PM Friday October 15th, 2021.

A 18% buyers premium will be added to all online purchases,

Your credit card added through the Bidspotter.com fully secure and PCI compliant registration process will be charged a $2000.00 deposit in order to be approved to bid within the auction. You will not be approved without your credit card entered at the stage of registration being charged a deposit of $2000.00

Credit Card Payments: Payments via credit card are accepted up to $2000.00 final invoice total (amounts more than $2,000.00 will be subject to a 3% administrative fee). Any invoice total larger than $2000.00 must be paid by wire transfer or certified check. Your deposit may be applied to your final invoice amount, even if your final invoice is larger than $2000.00

Removal deadline: Tuesday October 19th, 2021.

Accounting: Victoria 437-994-6586, vwhitman@infinityassets.com

Banking Information (Wire Transfers):

USD WIRE TRANSFER INSTRUCTIONS:

BENEFICIARY BANK:

RBC ROYAL BANK

3300 HIGHWAY #7, WEST

CONCORD, ONTARIO L4K 1A5

BENEFICIARY NAME:

INFINITY ASSET SOLUTIONS INC.

63 MAPLECRETE ROAD

CONCORD, ONTARIO L4K 1A5

ACCOUNT #: 4010286

TRANSIT #: 00192

BANK #: 003

SWIFT CODE: ROYCCAT2

FOR CUSTOMERS FROM USA:

INTERMEDIARY BANK: J.P. MORGAN, NEW YORK

ABA#: 021000021

IBAN #: 003401028600192

Terms and Conditions of Sale Persons participating in the auction shall be bound by ALL of the following terms and conditions, which are subject to amendments and modifications by the Auctioneer at the time of auction. 1. This catalogue is meant merely as a guide. The Auctioneer believes the descriptions contained herein to be correct, but make no warranty in connection therewith. 2. Auctioneer reserves the right to sell subject to reserve and to bid for its own account and for the accounts of others, whether by verbal or written proxy, all lots are subject to prior sale. 3. The Auctioneer reserves the right to refuse any applicant the privilege of bidding or attending at the auction and may revoke such privilege at any time. 4. All Articles will be sold to the highest bidder conforming to the bid process, provided that the Auctioneer reserves the right to sell articles by individual, group lots and “in bulk,” as he deems appropriate. The Auctioneer reserves the right to sell on behalf of third parties, its own account or on the account of others. Should any dispute arise between two or more bidders or as to any bid, the lot in question may, at the Auctioneers discretion, be immediately put up again and resold. The Auctioneer shall regulate all matters relating to the conduct of the auction and his decision shall be final and binding on all bidders. The record kept by the clerk of sale, shall in all cases be accepted by the bidder as final. 5. All sales shall be concluded as indicated by the Auctioneer and no Purchaser may thereafter revoke his bid. Title to the lots purchased shall not pass until payment in full of the purchase price is received. 6. ALL SALES ARE FINAL, ON AN “AS IS WHERE IS,” “IN PLACE” “WITH ALL FAULTS” BASIS WITH NO CONDITIONS OR WARRANTIES WHETHER EXPRESSED OR IMPLIED, STATUTORYOR OTHERWISE, INCLUDING WITHOUT LIMITATION, WARRANTIES OR CONDITIONS, AS TO TITLE, DESCRIPTION, FITNESS FOR PURPOSE, QUANTITY, QUALITY, MERCHANTABILITY, STATE, CONDITION, LOCATION OR OTHERWISE. NO SALE SHALL BE INVALIDATED AND THE AUCTIONEER SHALL HAVE NO LIABILITY FOR A MISDESCRIPTION OF ANY ARTICLE OR LOT WHETHER CONTAINED IN A CATALOGUE, ADVERTISEMENT, OR OTHERWISE. DESCRIPTIONS HAVE BEEN PREPARED FOR GUIDE PURPOSES ONLY AND SHALL NOT BE RULED UPON BY THE PURCHASER FOR ACCURACY OR COMPLETENESS. PLEASE INSPECT ALL ITEMS BEFORE BIDDING. PURCHASERS SHALL BE DEEMED TO HAVE RELIED ENTIRELY UPON THEIR OWN INSPECTIONS AND INVESTIGATIONS. 7. A deposit of equal to 25 percent of the purchases shall be made at the time of sale. The balance of the purchase price must be paid in full before or immediately after the conclusion of the auction. All payments must be in Cash, Certified Funds, Visa, MasterCard or Interac, Wire Transfers or Company Checks must be accompanied with a bank letter guaranteeing irrevocable payment to Infinity Asset Solutions Inc. Deposits on account of purchases may be made in advance of the auction and the balance thereof will be refunded immediately after the auction. The Auctioneer reserves the right to put articles back up for auction if deposit is not received at or before the time of sale. 8. No article shall be removed unless paid for in full and articles purchased shall be removed within the guidelines and terms stipulated. The Purchaser shall be responsible for all the costs of removal and shall be liable for all damages, including without limitation, any environmental damage, caused during or as a result of the removal. Purchasers shall comply with all environmental laws and regulations including requirements as to bonding of movers. No claims shall be allowed after removal of the purchased article. 9. Where available, documents of transfer, including motor vehicle ownership documents, which are in possession of the Auctioneer, will be provided to the Purchaser following the auction or as soon thereafter as such documents are available. 10. No purchaser may assign, transfer or dispose of his rights in any article purchased before he has paid the purchase price in full. 11. Purchasers shall pay applicable federal and provincial taxes, or furnish exemption certificates at the time of payment for goods purchased. All purchases are subject to Federal Harmonized Sales Tax (H.S.T.) at all times (including buyer's premium). No exceptions whatsoever. 12. Time shall be of the essence. If a Purchaser fails to make payment of remove goods within the time periods hereinabove provided, the Auctioneer may resell the article purchased by auction, private contract or otherwise, as the Auctioneer in his discretion deems advisable, and the Purchaser shall be liable for the shortfall and all costs expenses, including but not limited to interest rates (a minimum of 1.5% per month or 18% per annum), legal fees, moving and storage (a minimum rate of $2.00/sq.ft. per month) and commissions, incurred such as resale. 13. The Auctioneer assumes no responsibility or any liability once title passes, which occurs at time of payment in full. Purchasers are advised to prearrange for insurance coverage of their purchase. Title will revert to the seller in the event purchaser does not remove his purchases by the time specified. 14. If the Auctioneer is unable to deliver an article sold to a Purchaser due to fire, theft or any other reason whatsoever, the Auctioneer shall reimburse the Purchaser for all monies paid to the Auctioneer in respect of the article and the Auctioneer shall have no further liability to the Purchaser arising from or relating to such loss, including without limitation, any damages or loss of profits. 15. Bidders acknowledge that any auction site is a potentially dangerous place with noxious, corrosive and pressurized substances being present, heavy equipment being operated and electric circuits being live. Every person at the Auction Site before, during and after the auction sale shall be deemed to be there at their own risk with notice of the condition of the premises, the activities on the premises and the conduct of third parties, and the Bidder shall so advise his/her agents and employees. No person shall have any claim against the auctioneer, his agents, employees or principals for any injuries sustained for damages to or loss of property which may occur from any cause whatsoever.

EQUIPMENT REMOVAL PROCEDURES TERMS & CONDITIONS

The following are the standard procedures and terms and conditions for the removal of equipment or other items purchased at an Infinity Asset Solutions Inc. (“Infinity”) sale:

- All invoices must be paid in full prior to removal of equipment/ Each invoice must be marked “Paid in Full” and initialed by an authorized Infinity representative.

- All buyers are solely responsible for coordinating the removal of items purchased at the Auction and all associated costs.

- Buyers are responsible for, at their expense: a. Proper and safe disconnection and termination of all electrical, gas, water and/or air lines to machines conforming to all governing building codes; b. Shearing flush to the floor of all anchor bolts or fasteners; c. Erecting safety barriers around pits and holes in the floor created by removal of equipment until repaired; d. Repair all holes in the floor, walls or roof created by the removal of items purchased conforming to all governing building codes; e. Removing, off premises, machine oils and all hazardous materials (including all contaminants) contained in items purchased; f. Repairing all damage cased to the premises by a buyer, its representative or any other party hired by a buyer for the removal of items purchased; g. Leaving the work area in a clean, broom-swept condition conforming to all governing building codes; h. Any other specific terms and conditions communicated by Infinity before, during or after the auction sale; i. Removal of items purchased by the time and date set by Infinity before, during or after the auction sale; and j. The safety of all of a buyer’s employees, agents or representatives including all movers/riggers hired by such buyer.

- Prior to removal, all buyers, or any movers or riggers hired by a buyer, must provide to Infinity a satisfactory certificate of insurance evidencing at leas $5,000,000 in comprehensive liability insurance coverage (including workers compensation and automobile) per person, per occurrence.

- Prior to removal, an authorized Infinity representative must examine and approve the removal of all items purchased at the sale. Such approval shall be indicated by this representative initialing all invoices.

- No items shall be removed until after the auction sale. Removal hours are weekdays only between 8:00 a.m. and 4:00 p.m. unless otherwise specified.

- Buyers and their movers/riggers are jointly and severally liable for all damages, costs and expenses to the premises or any other assets which were cased by any of them, their employees, agents or representatives whether through negligence or otherwise. The Buyer indemnifies and saves Infinity harmless from any and all costs, expenses and claims suffered or incurred by Infinity as a result of any act or omission of such buyer and/or any mover or rigger retained by a buyer.

NO ITEMS SHALL LEAVE THE PREMISES UNTIL THE ABOVE HAS BEEN COMPLIED WITH TO INFINITY’S SATISFACTION.

NOTE: Buyers, please provide all movers or riggers hired by you with a copy of these procedures/terms and conditions as you will be held liable for their conduct.