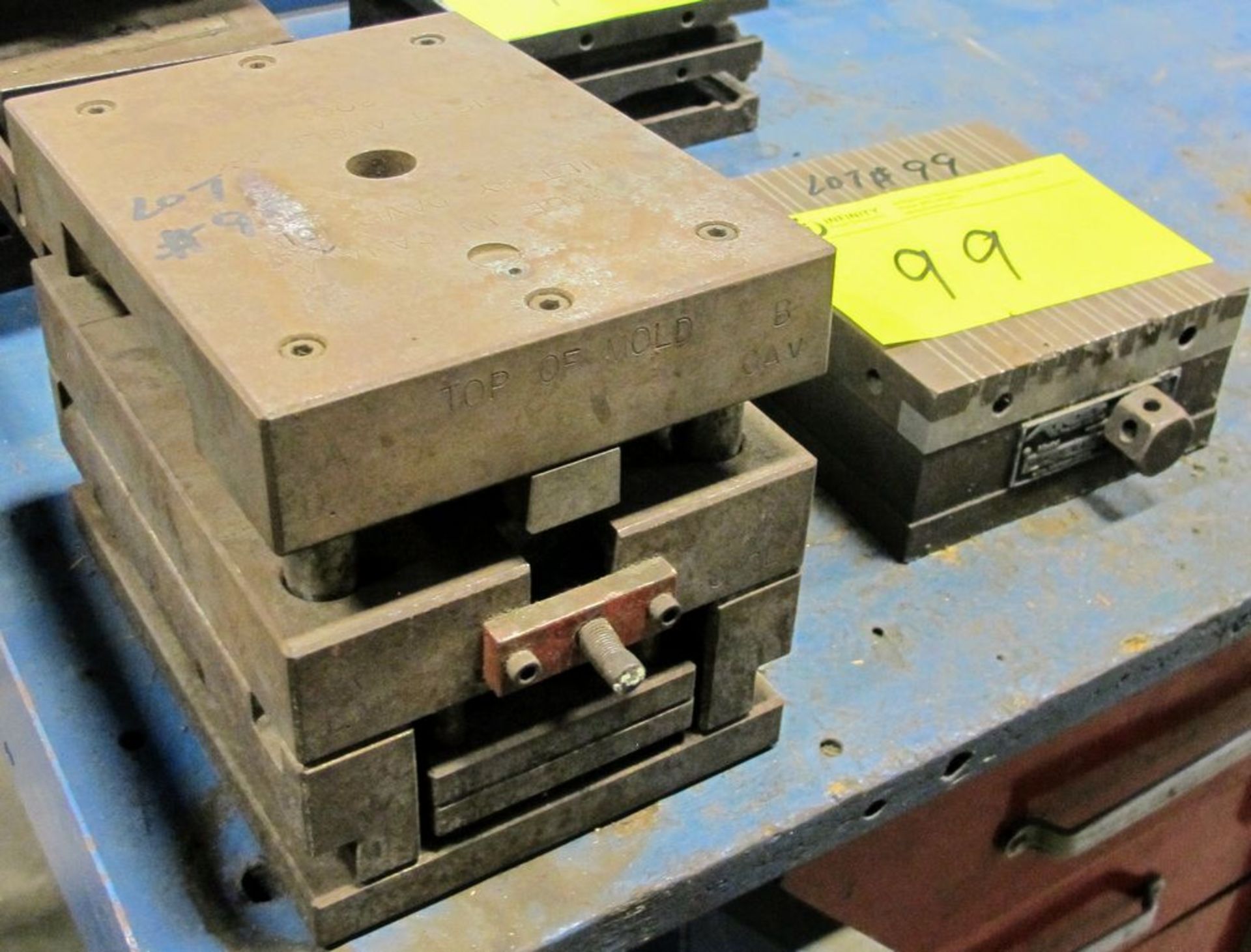

99

LOT (2) MAGNETIC SINE PLATES

LOT (2) MAGNETIC SINE PLATES

LOT (2) MAGNETIC SINE PLATES

Comber Tool & Mold Eng. Inc.

Ends from

Venue Address

For Infinity Asset Solutions Inc delivery information please telephone 905-669-8893.

Important Information

Comber Tool & Mold Eng. Inc.

Date & Time: Lots starts closing on Tuesday, November 19, at 11:00 am

Location: 6537 Taylor Ave, Comber, ON N0P 1J0

Inspection Date: Monday November 18th, 9AM - 4PM or By Appointment

Industry: CNC Machining

18% Buyers Premium applies on all online purchases.

A $2000 refundable security deposit is required upon online registration. See Terms & Conditions Below.

Featuring:

EDM’s

2018 MAKINO U6 Wire EDM (installed Feb 2019), Hyper i CNC Control, s/n W150740, Travels: X-650mm, Y-450mm, Z-420mm, Tank Size 770mm x 590mm, Hyper I Controller, 10 thou and 12 thou PICO guides, 16kg wire spool option, HyperConnect remote access and operation (EDM Viewer & EDM Mail) option, GS-Cut (Belly Wizard) technology, ProTech rust protection, Dual Flush Pumps, Automatic Wire Threading System, “1-Click” Energizer Indexing, Dual Filers with one touch “Air Purge”, Wire Cleaning & Drying system, Multi-function Handbox with digital readout

(2) 2016 SODICK VZ500L Wire EDM, LN2W Control, s/n’s T0310, T0311, Travels: X-500mm, Y-350mm, Z-250mm

2003 SODICK AQ750L Wire EDM, LN1W Control, s/n 0129, Travels: X-29.5”, Y-19.6”, Z-15.7”, 3,300lb Max Workpiece Weight

2002 SODICK AQ750L Wire EDM, LN1W Control, s/n 9058, Travels: X-29.5”, Y-19.6”, Z-15.7”, 3,300lb Max Workpiece Weight

2008 SODICK AD325L Wire EDM, LN1W Control, s/n 0125, Travels: X-320mm, Y-250mm, Z-220mm

2004 SODICK AQ325L Wire EDM, LQ1W Control, s/n 2056, Travels: X-13.7”, Y-9.8”, Z-8.6”, UV-3.1”, Boyu LN-5800 Water Chiller

2003 SODICK AQ325L Wire EDM, LQ1W Control, s/n 1686, Travels: X-13.7”, Y-9.8”, Z-8.6”, UV-3.1”, Boyu LN-5800 Water Chiller

ONA Datic D-360-F Sinker EDM, Datic F60 Control, 16” x 24” Table, s/n 6646/9411

JEM 350 Sinker EDM, 10” x 24” Table, s/n 900349

CNC Vertical Machining Centers

(2) 2015/14 MAKINO F5 CNC Vertical Machining Center, s/n’s V150851, V150789 (Approx. 7,721 Spindle Hrs), 20” x 40” Table (1000mm x 500mm), Makino Professional 5 CNC Control, Travels: X-900mm, Y-500mm, Z-400mm, 20,000 RPM, HSK-A63, Probe, (30) ATC, Blum Laser, Dual Auger Chip Recovery, Oil Matic Oil Temperature Regulator, SMC Air Dryer, 0.05 Micron Glass Scales, Makino’s Core Cooled and Under Race Lubricated Spindle Technology, Makino’s Super Geometric Intelligence (SGI.4)

(2) 2013/2012 MAKINO F3 CNC Vertical Machining Center, s/n’s V140461 (Approx. 11,035 Spindle Hrs), V140342 (Approx. 15,960 Spindle Hrs), 20” x 34” Table (850mm x 500mm), Makino Professional 5 CNC Control, Travels: X-650mm, Y-500mm, Z-450mm, 20,000 RPM, HSK-A63, Probe, (30) ATC, Blum Laser, Oil Matic Oil Temperature Regulator, SMC Air Dryer, 0.05 Micron Glass Scales, Makino’s Core Cooled and Under Race Lubricated Spindle Technology, Makino’s Super Geometric Intelligence (SGI.4)

(2) 2002 HURON KX8 CNC Vertical Machining Center, s/n’s 01B262 (New Spindle), B01262, 24” x 32” Table, Siemens CNC Control, Travels: X-700mm, Y-600mm, Z-450mm, 24,000 RPM, HSK-A63, (20) ATC, Chip Conveyor

MATSUURA MC-1000VF CNC Vertical Machining Center, 20” x 44” Table, Matsuura EN4-1400A CNC Control, (30) ATC, 40 Taper, s/n 930610589

CNC Bridge Type Vertical Machining Centers

2000 NICOLAS CORREA FP-40/40 CNC Bridge Type Vertical Machining Center, s/n 8951101, 50” x 160” Table (4000mm x 1250mm), 80” Between Housings (2500mm), Heidenhain CNC Control, Travels: X-3500mm, Y-3000mm, Z-1000mm, 50 Taper, Horizontal Spindle, Dual Chip Conveyor

NICOLAS CORREA FP-30/30 CNC Bridge Type Vertical Machining Center, s/n 8900104, 49” x 120” Table (3000mm x 1250mm), 69” Between Housings (1680mm), Heidenhain CNC Control, Travels: X-2500mm, Y-1800mm, Z-800mm, 50 Taper, Horizontal Spindle

2001 NICOLAS CORREA Euro-2.000 CNC Bridge Type Vertical Machining Center, s/n 900054, 40” x 80” Table (1000mm x 2000mm), 49” Between Housings, GE Fanuc Series 16i-M CNC Control, Travels: X-2000mm, Y-1250mm, Z-650mm, CAT40, ATC, Dual Auger Chip Recovery

NICOLAS CORREA Euro-2.000 CNC Bridge Type Vertical Machining Center, s/n 9000104, 40” x 80” Table (1000mm x 2000mm), 49” Between Housings, GE Fanuc Series 16i-M CNC Control, Travels: X-2000mm, Y-1250mm, Z-650mm, CAT40, ATC, Dual Auger Chip Recovery w/ 4th Axis & Tailstock

Boring Mill

TOSHIBA SHIBAURA BTD-9 Table Type Horizontal Boring Mill, Tosnuc CNC Control, 4” Spindle, 35” x 40” 4th Axis Powered Rotary Table, Cat 50, 1,250 RPM, s/n 113518

CNC Lathes

NAKAMURA-TOME SC-300 CNC Lathe, Fanuc Series 21-T CNC Control, 10” 3-Jaw Chuck, Tailstock, Turret, Chip Conveyor, Micro Air Dust Collector

Milling Machines

BRIDGEPORT Vertical Milling Machine, 9” x 42” Table, Heidenhain 2-Axis DRO, 2HP, 4,200 RPM

(2) MAXIMART S-3VS Vertical Milling Machine, s/n’s 991404, 991073, 10” x 50” Table, Newall 2-Axis DRO, 3HP, 4,300 RPM

KONDIA FV-1 Vertical Milling Machine, 12” x 48” Table, Heidenhain 2-Axis DRO, 4,000 RPM, s/n U-440

KONDIA FV-1 Vertical Milling Machine, 12” x 48” Table, 4,000 RPM, s/n T-711

Lathes

CHIEN YEH STRONG 1500 Engine Lathe, 3-Jaw Chuck, 20” Swing, 74” Bed, Tailstock, Tool Post, 1,800 RPM, 2” Bore

Quality Control

LK G-90C CMM, 79” x 53.5”, s/n G90C/16955/99 w/ LK Power Supply, Renishaw PH9A Probe, Renishaw PI 200 Probe Interface, Renishaw PHC9 Controller, Wilkerson A00-AH-Q81 Air Dryer

2003 LK Integra CMM, 43” x 41”, s/n IN/57301/03 w/ LK Power Supply, Renishaw PHT10 Probe, LK Pendant, Renishaw PHC 10-2 Controller, Renishaw PI200 Interface

DEA A00C CNC Swift CMM, 35” x 29.5”, DEA TU01 Pendant, Power Supply

MITUTOYO PH-3500 Profile Projector, Mitutoyo Micropak 2 2-Axis DRO, s/n 800112

Surface Grinders

BLOHM-HFS Surface Grinder, 20” x 48” Magnetic Chuck, s/n 1101008, Neutrofier III Control Station

NICCO NSG-6H Surface Grinder, 12” x 24” Magnetic Chuck, s/n G4205

(2) BROWN & SHARPE 618 Micromaster Surface Grinder, 6” x 18” Magnetic Chuck, s/n’s 523-6181-1993, 523-6181-5794

Forklifts

HYSTER S60XM Propane Forklift, 6,000lb Cap., 126.4” Max Lift, 2-Stage Mast, Side Shift, Cushion Tires, s/n D187C03594T

TCM FCG25-4L Propane Forklift, 4,300lb Cap., 189” Max Lift, 3-Stage Mast, Side Shift, Outdoor Tires, s/n N/A

Vehicles

2006 DODGE Ram 2500 Pickup Truck, Cummins Turbo Diesel, VIN# 3D3KS26C26G252909

2000 DODGE Ram 2500 Pickup Truck, Cummins 24 Valve Turbo Diesel, Laramie SLT, VIN# 3B7KC26691M516234

Support Equipment

2015 ATLAS COPCO GA37VSD+ FF Air Compressor, 50HP, s/n AP1828409

2000 ATLAS COPCO GA37 Air Compressor, 50HP, s/n AII 366302

Hydraulic Press, Approx. 150 Ton Cap., 45” x 56” Bed, Pit Mounted

WMW Heckert Radial Arm Drill, 5’ Arm

ROUBAX VERTICUT 115-A Roll-in Saw, s/n 486

RUEMELIN AG Sandblast Cabinet, 60” x 36”, s/n 34806

RUEMELIN D5698 Dust Collector, 375 Gallon, s/n 34807

RUSCH HBS 250 Horizontal Bandsaw

MILLER Syncrowave 300 Welder w/ Miller Coolmate V3 Cooling Unit

HOBART Welder w/ Wire Feeder

TORRIT Dust Collector

40’ Seacan

PLUS: HSK-A63, 40 & 50 Taper Tool Holders, Tool Holder carts, Lista Cabinets, Drill Bits, End Mills, Reamers, Precision Instruments, Granite Plates, Hoist Systems, Heavy Duty Carts, Workbenches, Metal Shelving, Chillers, Transformers, KURT Vises, Toolboxes, Power & Hand Tools, Angle Plates, Lift Carts, Bar Stock, Hydraulic Power Packs, Wire, Motors, Warehouse Fans, Grinding Wheels, Jib Cranes, Dump Hoppers, Pedestal Grinders, Lifting Chains & Magnets, Tool/Cutter Grinders and Much More!

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

PAYMENT: All payments must be in either Cash, Certified Cheque, Wire Transfers or Company Checks must be accompanied with a bank letter guaranteeing irrevocable payment to Infinity Asset Solutions Inc., Visa & Mastercard will be accepted for total payments of $2,000.00 or less.

Payment is due by:

A 18% buyers premium will be added to all online purchases,

Your credit card added through the Bidspotter.com fully secure and PCI compliant registration process will be charged a $2000.00 deposit in order to be approved to bid within the auction. You will not be approved without your credit card entered at the stage of registration being charged a deposit of $2000.00

Credit Card Payments: Payments via credit card are accepted up to $2000.00 final invoice total. Any invoice total larger than $2000.00 must be paid by wire transfer or certified check. Your deposit may be applied to your final invoice amount, even if your final invoice is larger than $2000.00

Removal: Friday November 29, 2019

Site Supervisor: Charlie 519-791-1162

Accounting: Victoria 437-994-6586, vwhitman@infinityassets.com

Banking Information (Wire Transfers):

Canadian WIRE TRANSFER INSTRUCTIONS.

Beneficiary Bank: ROYAL BANK OF CANADA

3300 HIGHWAY #7

CONCORD, ONTARIO

Beneficiary Customer:

INFINITY ASSET SOLUTIONS INC.

ACCOUNT #: 1007137

TRANSIT #: 00192

BANK #: 003

SWIFT # ROYCCAT2

Terms and Conditions of Sale Persons participating in the auction shall be bound by ALL of the following terms and conditions, which are subject to amendments and modifications by the Auctioneer at the time of auction. 1. This catalogue is meant merely as a guide. The Auctioneer believes the descriptions contained herein to be correct, but make no warranty in connection therewith. 2. Auctioneer reserves the right to sell subject to reserve and to bid for its own account and for the accounts of others, whether by verbal or written proxy, all lots are subject to prior sale. 3. The Auctioneer reserves the right to refuse any applicant the privilege of bidding or attending at the auction and may revoke such privilege at any time. 4. All Articles will be sold to the highest bidder conforming to the bid process, provided that the Auctioneer reserves the right to sell articles by individual, group lots and “in bulk,” as he deems appropriate. The Auctioneer reserves the right to sell on behalf of third parties, its own account or on the account of others. Should any dispute arise between two or more bidders or as to any bid, the lot in question may, at the Auctioneers discretion, be immediately put up again and resold. The Auctioneer shall regulate all matters relating to the conduct of the auction and his decision shall be final and binding on all bidders. The record kept by the clerk of sale, shall in all cases be accepted by the bidder as final. 5. All sales shall be concluded as indicated by the Auctioneer and no Purchaser may thereafter revoke his bid. Title to the lots purchased shall not pass until payment in full of the purchase price is received. 6. ALL SALES ARE FINAL, ON AN “AS IS WHERE IS,” “IN PLACE” “WITH ALL FAULTS” BASIS WITH NO CONDITIONS OR WARRANTIES WHETHER EXPRESSED OR IMPLIED, STATUTORYOR OTHERWISE, INCLUDING WITHOUT LIMITATION, WARRANTIES OR CONDITIONS, AS TO TITLE, DESCRIPTION, FITNESS FOR PURPOSE, QUANTITY, QUALITY, MERCHANTABILITY, STATE, CONDITION, LOCATION OR OTHERWISE. NO SALE SHALL BE INVALIDATED AND THE AUCTIONEER SHALL HAVE NO LIABILITY FOR A MISDESCRIPTION OF ANY ARTICLE OR LOT WHETHER CONTAINED IN A CATALOGUE, ADVERTISEMENT, OR OTHERWISE. DESCRIPTIONS HAVE BEEN PREPARED FOR GUIDE PURPOSES ONLY AND SHALL NOT BE RULED UPON BY THE PURCHASER FOR ACCURACY OR COMPLETENESS. PLEASE INSPECT ALL ITEMS BEFORE BIDDING. PURCHASERS SHALL BE DEEMED TO HAVE RELIED ENTIRELY UPON THEIR OWN INSPECTIONS AND INVESTIGATIONS. 7. A deposit of equal to 25 percent of the purchases shall be made at the time of sale. The balance of the purchase price must be paid in full before or immediately after the conclusion of the auction. All payments must be in Cash, Certified Funds, Visa, MasterCard or Interac, Wire Transfers or Company Checks must be accompanied with a bank letter guaranteeing irrevocable payment to Infinity Asset Solutions Inc. Deposits on account of purchases may be made in advance of the auction and the balance thereof will be refunded immediately after the auction. The Auctioneer reserves the right to put articles back up for auction if deposit is not received at or before the time of sale. 8. No article shall be removed unless paid for in full and articles purchased shall be removed within the guidelines and terms stipulated. The Purchaser shall be responsible for all the costs of removal and shall be liable for all damages, including without limitation, any environmental damage, caused during or as a result of the removal. Purchasers shall comply with all environmental laws and regulations including requirements as to bonding of movers. No claims shall be allowed after removal of the purchased article. 9. Where available, documents of transfer, including motor vehicle ownership documents, which are in possession of the Auctioneer, will be provided to the Purchaser following the auction or as soon thereafter as such documents are available. 10. No purchaser may assign, transfer or dispose of his rights in any article purchased before he has paid the purchase price in full. 11. Purchasers shall pay applicable federal and provincial taxes, or furnish exemption certificates at the time of payment for goods purchased. All purchases are subject to Federal Harmonized Sales Tax (H.S.T.) at all times. No exceptions whatsoever. 12. Time shall be of the essence. If a Purchaser fails to make payment of remove goods within the time periods hereinabove provided, the Auctioneer may resell the article purchased by auction, private contract or otherwise, as the Auctioneer in his discretion deems advisable, and the Purchaser shall be liable for the shortfall and all costs expenses, including but not limited to interest rates (a minimum of 1.5% per month or 18% per annum), legal fees, moving and storage (a minimum rate of $2.00/sq.ft. per month) and commissions, incurred such as resale. 13. The Auctioneer assumes no responsibility or any liability once title passes, which occurs at time of payment in full. Purchasers are advised to prearrange for insurance coverage of their purchase. Title will revert to the seller in the event purchaser does not remove his purchases by the time specified. 14. If the Auctioneer is unable to deliver an article sold to a Purchaser due to fire, theft or any other reason whatsoever, the Auctioneer shall reimburse the Purchaser for all monies paid to the Auctioneer in respect of the article and the Auctioneer shall have no further liability to the Purchaser arising from or relating to such loss, including without limitation, any damages or loss of profits. 15. Bidders acknowledge that any auction site is a potentially dangerous place with noxious, corrosive and pressurized substances being present, heavy equipment being operated and electric circuits being live. Every person at the Auction Site before, during and after the auction sale shall be deemed to be there at their own risk with notice of the condition of the premises, the activities on the premises and the conduct of third parties, and the Bidder shall so advise his/her agents and employees. No person shall have any claim against the auctioneer, his agents, employees or principals for any injuries sustained for damages to or loss of property which may occur from any cause whatsoever.