44

MJK0528 Protein Chip Manufacturing Line BULK LOT

1 Used Protein Chip Manufacturing Line BULK LOT

BULK LOT: Sum of lots (39, 40, 41, 42, 43, 45 ) must exceed the price of lot 44 in order for individual items to sell.

Consists of Lots:

MJK0335: Schenck Accurate Feeder

MJK0336: Reading Baking Solutions Clam Shell Continuous Mixer

MJK0337: Reading Baking Systems Rotary Presser/Sheeter

MJK0338: Rotary Cutter With Extra Dies

MJK0339: Transfer Conveyor

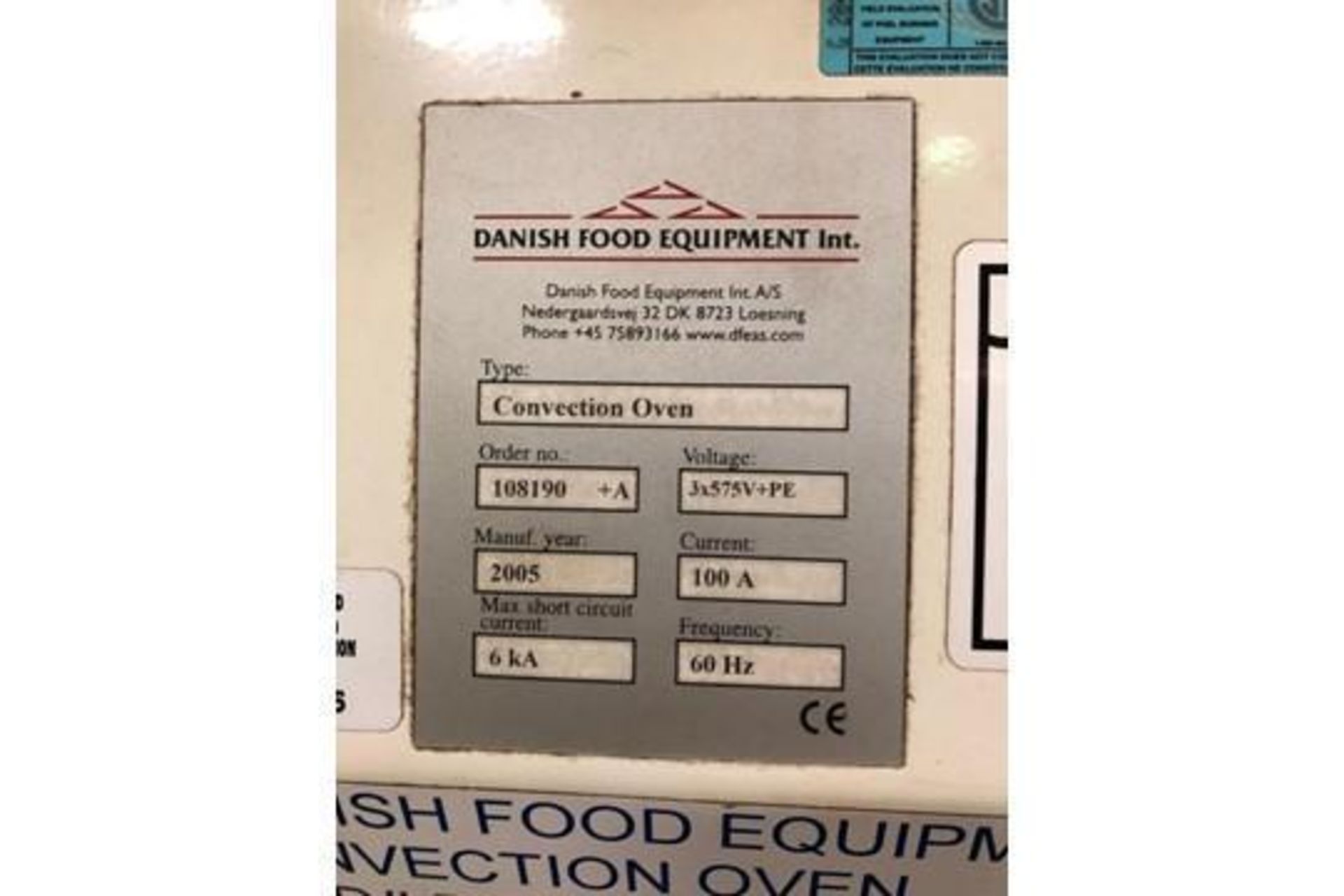

MJK0551: Danish Food Equipment Oven

READING BAKERY SYSTEM CMS 400kg/hr 4 years old

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

Continuous mixing produces a more consistent product and eliminates undesirable batch to batch dough variations

Optimizes food safety by ensuring dough is never exposed to the environment during mixing

Clam-shell design for easy cleaning and maintenance

Reduced energy, labor costs, and smaller production footprint

Precise and uninterrupted ingredient delivery to the mixer

Dough production rates From 100 to 1,250 kg/hour

Schenck Accurate Feeder. Model 1100233619-10A. S/N PFPPB-001

The ability to accurately and consistently meter ingredients into a continuous mixer is critical to the quality and consistency of the product at the mixer discharge

Gravimetric, Loss-in-Weight technology provides precise, uninterrupted dry ingredient metering

Ingredient refills are programmed in advance and controlled by the touchscreen control interface

Flow-meters connected to the closed loop control system ensures that the liquid ingredients are accurately delivered in coordination with the dry ingredients

Liquid addition system for mixer made in 2012, features two lee 30 DB stainless tanks, rated for 250 degrees. Both with flowmeters and 1HP pump

Reading Bakery Continuous Mixer, MODEL# 0X001-000-2013-7099 SERIAL# J115043-040

Mezzanine for blending system 480VAC 3-phase 200A power requirement

FABRICATED CHIP SHEETER and ROTARY CUTTER

Consistent production of sheeted snacks.

The Thomas L. Green Fabricated Chip Sheeter is a forming machine capable of sheeting and cutting shapes from potato doughs consisting of dry premixes, potato flakes, whole grains, corn and other formulations. Dough is delivered to a hopper above two large-diameter, solid core, water-cooled sheeting rolls. In a single pass, dough is reduced and sheeted to a typical thickness of 0.7mm (.027”). Cut shapes are delivered directly into an oven or fryer prior to seasoning and packaging, sheeter die/cutter for chips by Reading Bakery Systems Rotary Cutter.

ROTARY CUTTING STATION

Precisely cut product shapes.

The Thomas L. Green Rotary Cutting Station accurately and continuously cuts distinct product shapes out of a single dough sheet. An integrated conveyor system moves product through and is pressured against a rotating die assembly. Operators can adjust the pressure on the dough sheet during operation to ensure a thorough cut and consistent piece production. Model SH202-48-2013-7102, Serial Number J115043-080 with Dies by American Engraving designed potato chip cutter die, tortilla cutter die, and cereal inclusion die. By Reading Bakery Systems

Mesh belt 48’ wide x 120’ long, auto tracking, 575VAC/3-phase/100A system, 6MM BTU/hr total

Spray Dynamics (Heat & Control) Season Application System (tumbler/spraying/seasoning depositing)

Specifications:

Soft Flight® Coating Drum

Spray Dynamics® Soft Flight® Coating Drums are designed and engineered specifically to your product requirements.

Variable tilt frame assembly and product flight design exposes each piece of product to the application of liquid and dry coatings.

Our 304 stainless steel shell-in-shell cylinder drum provides sanitary operation and simple cleaning for snack, meat, dairy, and other process-specific applications.

Custom product flight configuration reduces breakage

304 stainless steel shell-in-shell cylinder

Wash down motor assembly with variable speed controller

NEMA 4 stainless steel control console

Portable casters with brake assembly

Coating Drum 36” dia x 82” long

MODEL SLURRY ENCOATER SERIAL# 1023

Spray Dynamics is a leader in providing the food industry with solutions for application of dry ingredients and other small particulates

The Scarf Plate provides even distribution of dry ingredients, nuts, seeds and many other small particulates.

The combination of Spray Dynamics Uni-SpenseTM and Scarf Plate can be mounted on a variety of stands designed to fit around most exit conveyors with positive tools-free locking mechanisms to ensure the scarf remains in the same position day after day

Danish Food Equipment Oven

1-Used 1.2 (48") Meter Wide Mesh Belt X 104' Long

PLC CONTROLS

5 ZONE

480v/3ph/60hz (Oven is 575 but comes with a down transformer)

New in 2005, refurbished in 2013, Great Shape Now!

Specifications:

- Manufactured by Delta Food Equipment (Owned by Meincke)

- Delta Three Tunnel Oven - 5 Zone

- Belt width: 1.2 meters wire mesh

- The oven is being used baking at 500F. Max temperature is 650F.

- It was being used to par bake pizza crusts, and recently chips prior to a dryer however, it will work with most types of flatbreads.

- It was only being used approximately 10 hours per week for flatbreads then was installed in 2013 for chips.

- Bake chamber: 104 ft long (can be set for 110 ft). Made up of 16 two meter sections.

- The intake section is 6 ft long and exit section is 8 ft long.

- Inspection hatch located on every section.

- Burners are Lo Nox Weishaupt new in 2013. Gas valves are new in 2013. Screen is Allen Bradley Panelview 1000. PLC system is Allen Bradley.

- We have full documentation on all electronics and programming.

Website: https://www.readingbakery.com/rotary-cutting-station-bakery-equipment.html

Location: El Monte, CA

Load Out: $TBD

Skidding: $TBD

1 Used Protein Chip Manufacturing Line BULK LOT

BULK LOT: Sum of lots (39, 40, 41, 42, 43, 45 ) must exceed the price of lot 44 in order for individual items to sell.

Consists of Lots:

MJK0335: Schenck Accurate Feeder

MJK0336: Reading Baking Solutions Clam Shell Continuous Mixer

MJK0337: Reading Baking Systems Rotary Presser/Sheeter

MJK0338: Rotary Cutter With Extra Dies

MJK0339: Transfer Conveyor

MJK0551: Danish Food Equipment Oven

READING BAKERY SYSTEM CMS 400kg/hr 4 years old

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

Continuous mixing produces a more consistent product and eliminates undesirable batch to batch dough variations

Optimizes food safety by ensuring dough is never exposed to the environment during mixing

Clam-shell design for easy cleaning and maintenance

Reduced energy, labor costs, and smaller production footprint

Precise and uninterrupted ingredient delivery to the mixer

Dough production rates From 100 to 1,250 kg/hour

Schenck Accurate Feeder. Model 1100233619-10A. S/N PFPPB-001

The ability to accurately and consistently meter ingredients into a continuous mixer is critical to the quality and consistency of the product at the mixer discharge

Gravimetric, Loss-in-Weight technology provides precise, uninterrupted dry ingredient metering

Ingredient refills are programmed in advance and controlled by the touchscreen control interface

Flow-meters connected to the closed loop control system ensures that the liquid ingredients are accurately delivered in coordination with the dry ingredients

Liquid addition system for mixer made in 2012, features two lee 30 DB stainless tanks, rated for 250 degrees. Both with flowmeters and 1HP pump

Reading Bakery Continuous Mixer, MODEL# 0X001-000-2013-7099 SERIAL# J115043-040

Mezzanine for blending system 480VAC 3-phase 200A power requirement

FABRICATED CHIP SHEETER and ROTARY CUTTER

Consistent production of sheeted snacks.

The Thomas L. Green Fabricated Chip Sheeter is a forming machine capable of sheeting and cutting shapes from potato doughs consisting of dry premixes, potato flakes, whole grains, corn and other formulations. Dough is delivered to a hopper above two large-diameter, solid core, water-cooled sheeting rolls. In a single pass, dough is reduced and sheeted to a typical thickness of 0.7mm (.027”). Cut shapes are delivered directly into an oven or fryer prior to seasoning and packaging, sheeter die/cutter for chips by Reading Bakery Systems Rotary Cutter.

ROTARY CUTTING STATION

Precisely cut product shapes.

The Thomas L. Green Rotary Cutting Station accurately and continuously cuts distinct product shapes out of a single dough sheet. An integrated conveyor system moves product through and is pressured against a rotating die assembly. Operators can adjust the pressure on the dough sheet during operation to ensure a thorough cut and consistent piece production. Model SH202-48-2013-7102, Serial Number J115043-080 with Dies by American Engraving designed potato chip cutter die, tortilla cutter die, and cereal inclusion die. By Reading Bakery Systems

Mesh belt 48’ wide x 120’ long, auto tracking, 575VAC/3-phase/100A system, 6MM BTU/hr total

Spray Dynamics (Heat & Control) Season Application System (tumbler/spraying/seasoning depositing)

Specifications:

Soft Flight® Coating Drum

Spray Dynamics® Soft Flight® Coating Drums are designed and engineered specifically to your product requirements.

Variable tilt frame assembly and product flight design exposes each piece of product to the application of liquid and dry coatings.

Our 304 stainless steel shell-in-shell cylinder drum provides sanitary operation and simple cleaning for snack, meat, dairy, and other process-specific applications.

Custom product flight configuration reduces breakage

304 stainless steel shell-in-shell cylinder

Wash down motor assembly with variable speed controller

NEMA 4 stainless steel control console

Portable casters with brake assembly

Coating Drum 36” dia x 82” long

MODEL SLURRY ENCOATER SERIAL# 1023

Spray Dynamics is a leader in providing the food industry with solutions for application of dry ingredients and other small particulates

The Scarf Plate provides even distribution of dry ingredients, nuts, seeds and many other small particulates.

The combination of Spray Dynamics Uni-SpenseTM and Scarf Plate can be mounted on a variety of stands designed to fit around most exit conveyors with positive tools-free locking mechanisms to ensure the scarf remains in the same position day after day

Danish Food Equipment Oven

1-Used 1.2 (48") Meter Wide Mesh Belt X 104' Long

PLC CONTROLS

5 ZONE

480v/3ph/60hz (Oven is 575 but comes with a down transformer)

New in 2005, refurbished in 2013, Great Shape Now!

Specifications:

- Manufactured by Delta Food Equipment (Owned by Meincke)

- Delta Three Tunnel Oven - 5 Zone

- Belt width: 1.2 meters wire mesh

- The oven is being used baking at 500F. Max temperature is 650F.

- It was being used to par bake pizza crusts, and recently chips prior to a dryer however, it will work with most types of flatbreads.

- It was only being used approximately 10 hours per week for flatbreads then was installed in 2013 for chips.

- Bake chamber: 104 ft long (can be set for 110 ft). Made up of 16 two meter sections.

- The intake section is 6 ft long and exit section is 8 ft long.

- Inspection hatch located on every section.

- Burners are Lo Nox Weishaupt new in 2013. Gas valves are new in 2013. Screen is Allen Bradley Panelview 1000. PLC system is Allen Bradley.

- We have full documentation on all electronics and programming.

Website: https://www.readingbakery.com/rotary-cutting-station-bakery-equipment.html

Location: El Monte, CA

Load Out: $TBD

Skidding: $TBD

Nutra Manufacturing & Packaging Equipment

Ends from

General delivery information available from the auctioneer

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Important Information

Nutra Manufacturing & Packaging Equipment

AUCTION DATE: lots start closing on Tuesday, June 8th at 10:00 am PT

LOCATION: 1310 Mountain View Circle, Azusa, California

INSPECTION: By appointment only. Please contact us to schedule. 818-495-3038

PICKUP: TBD

RIGGING:

There is no self-rigging. All Rigging and Load out will be completed by a contracted and approved Rigger.

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com