67

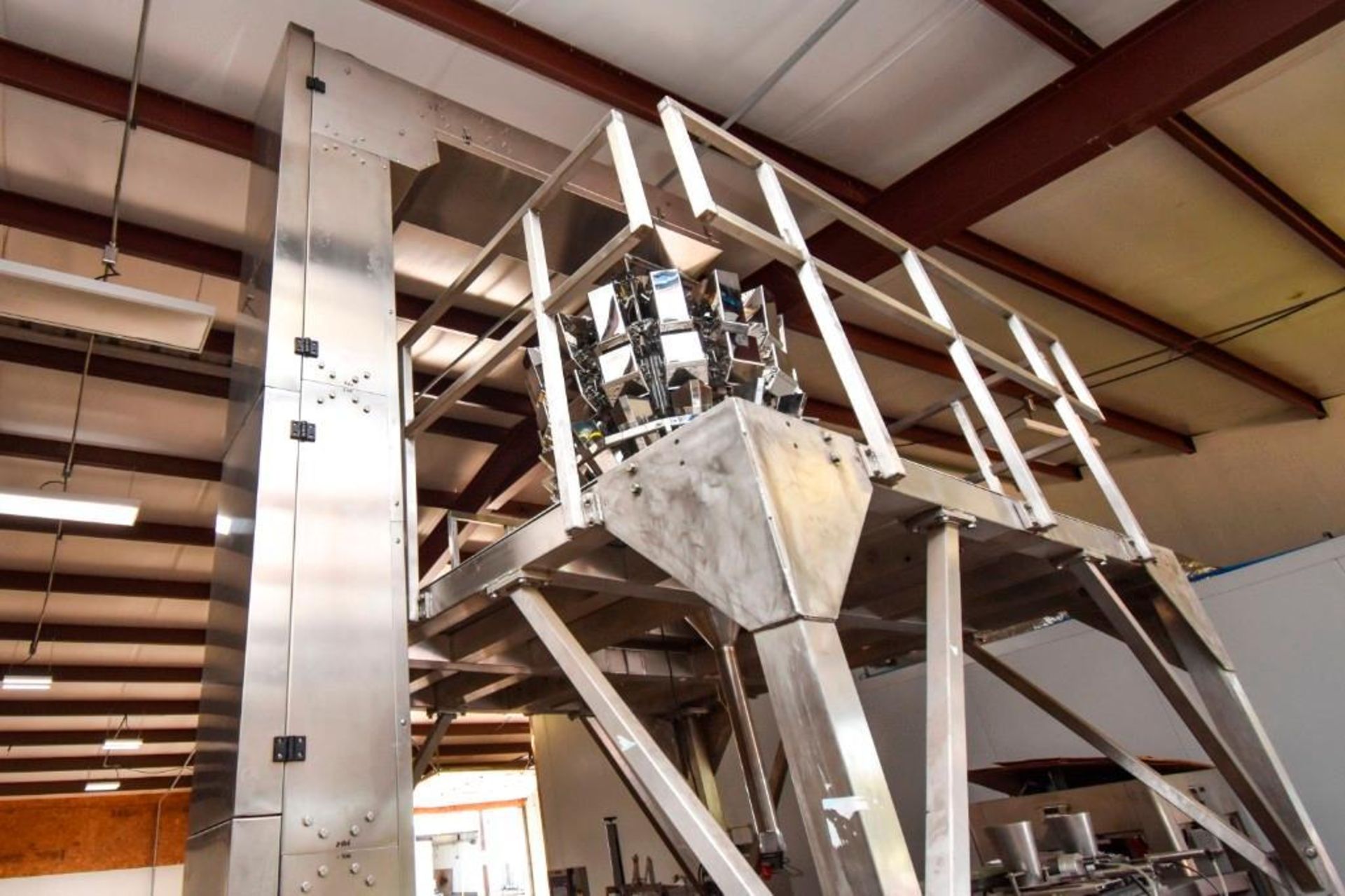

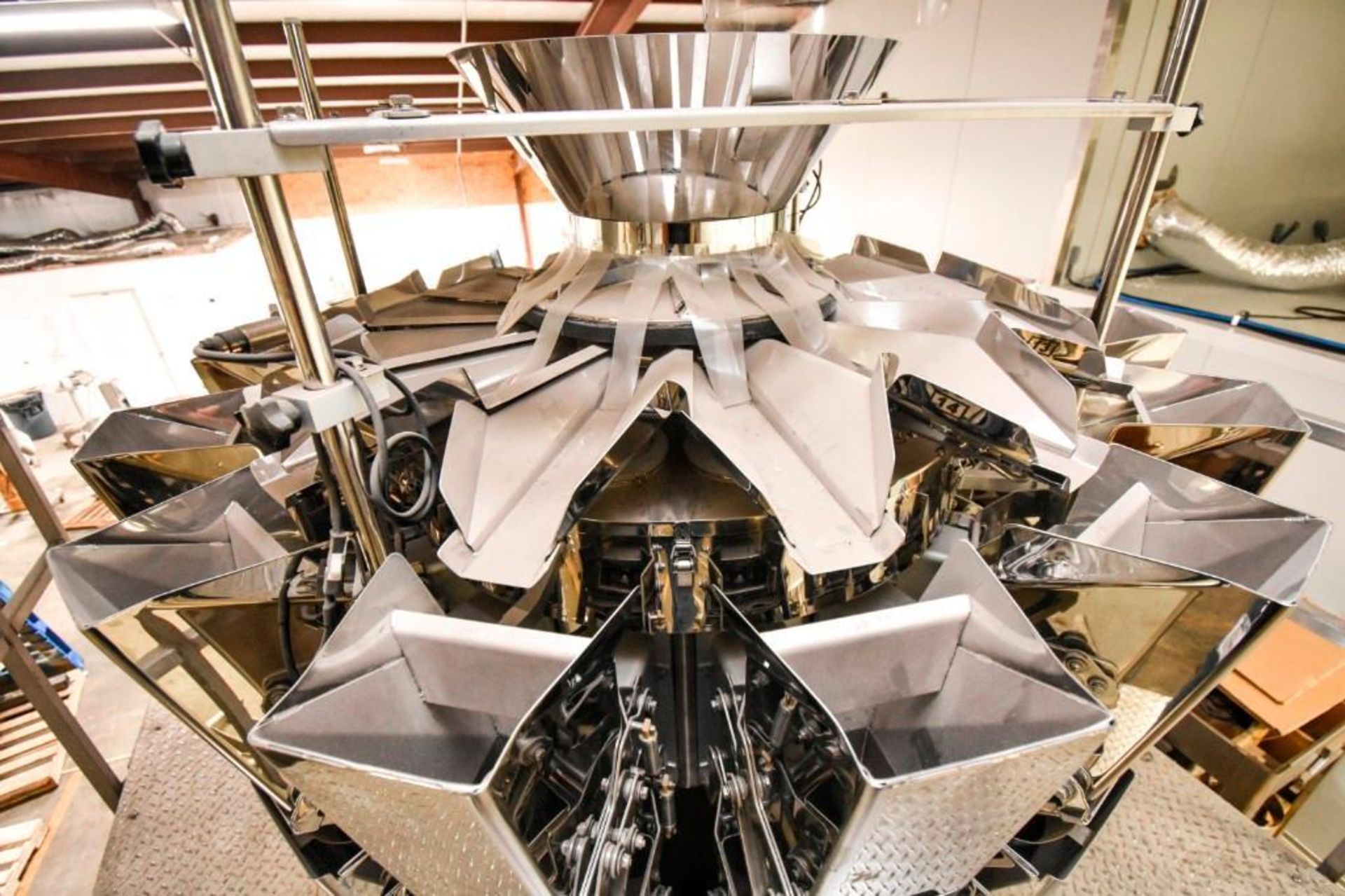

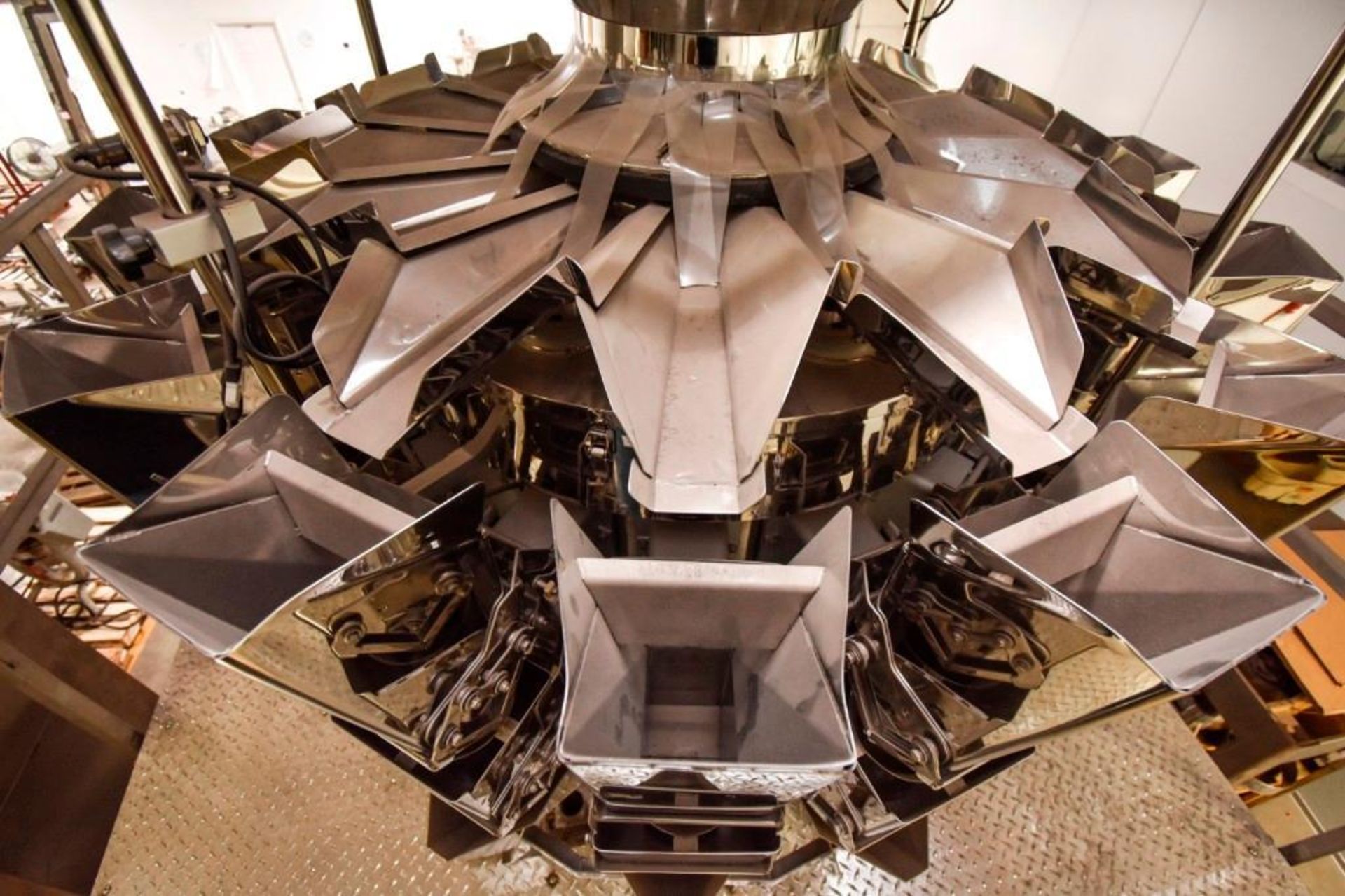

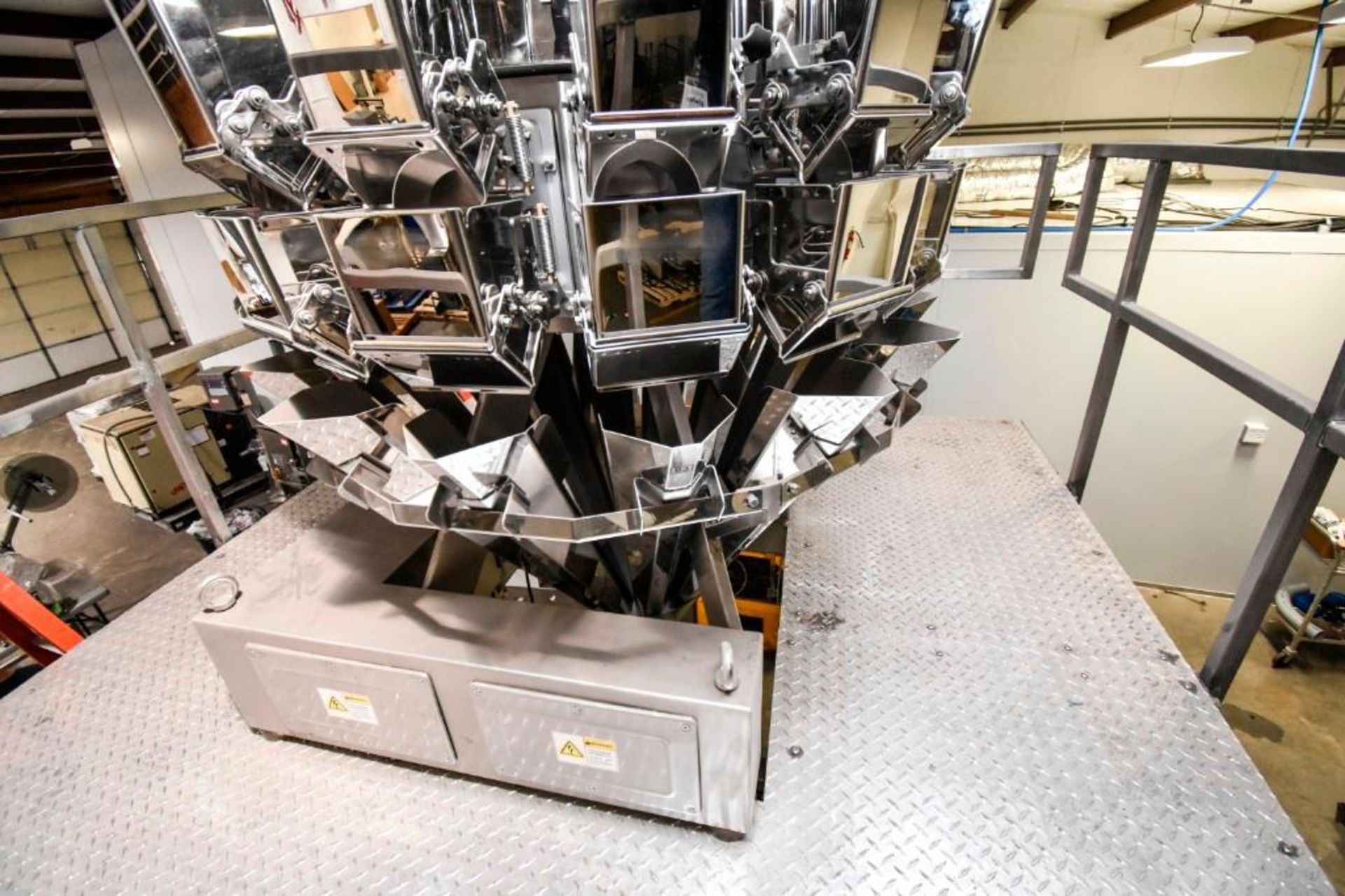

14 Head Scale with 2 APPE DOY 100 Pouch Filling Machine

1 Used 14 Head Scale with 2 APPE DOY 100 Pouch Filling Machine

Standard Technical Data

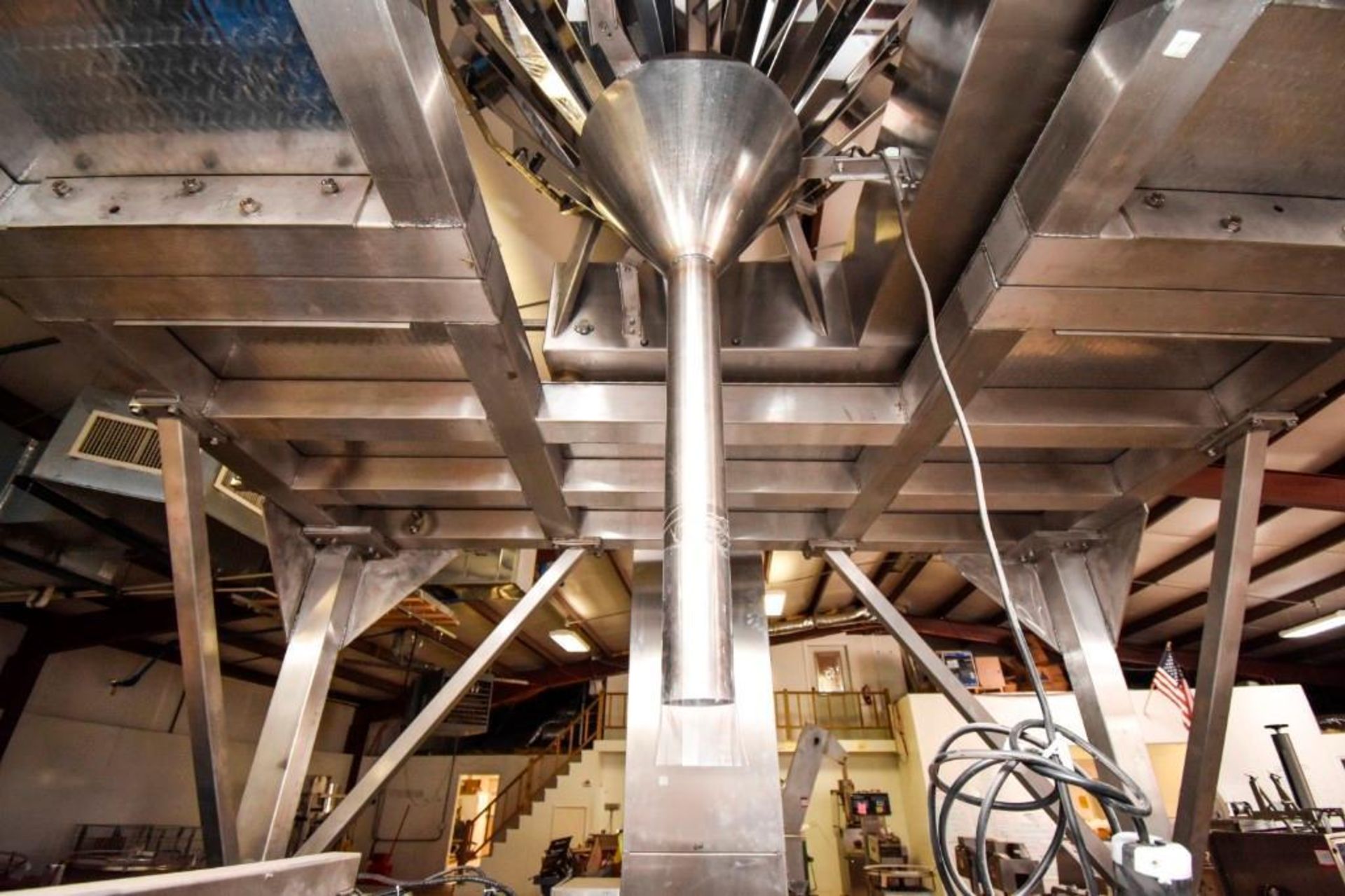

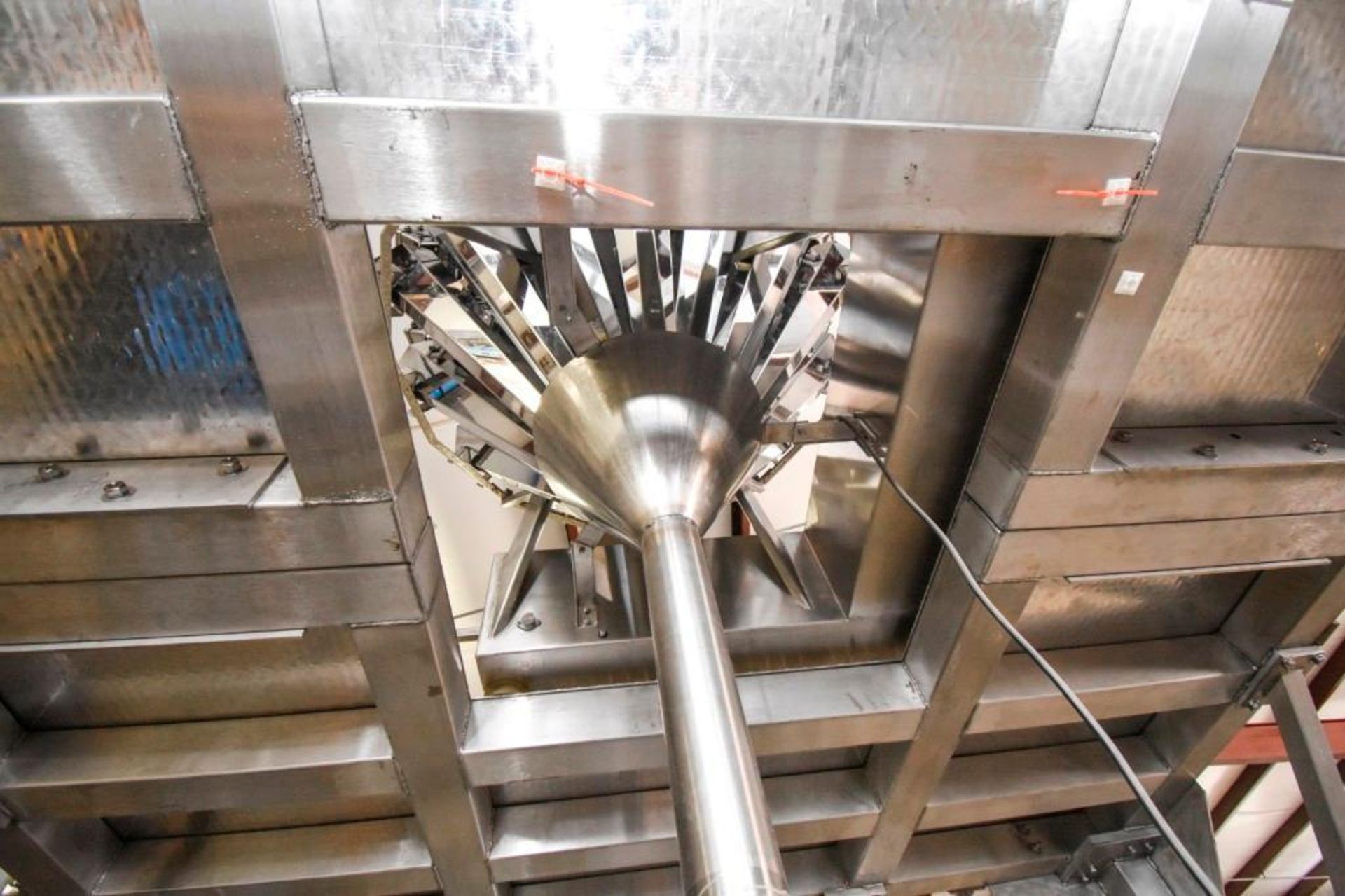

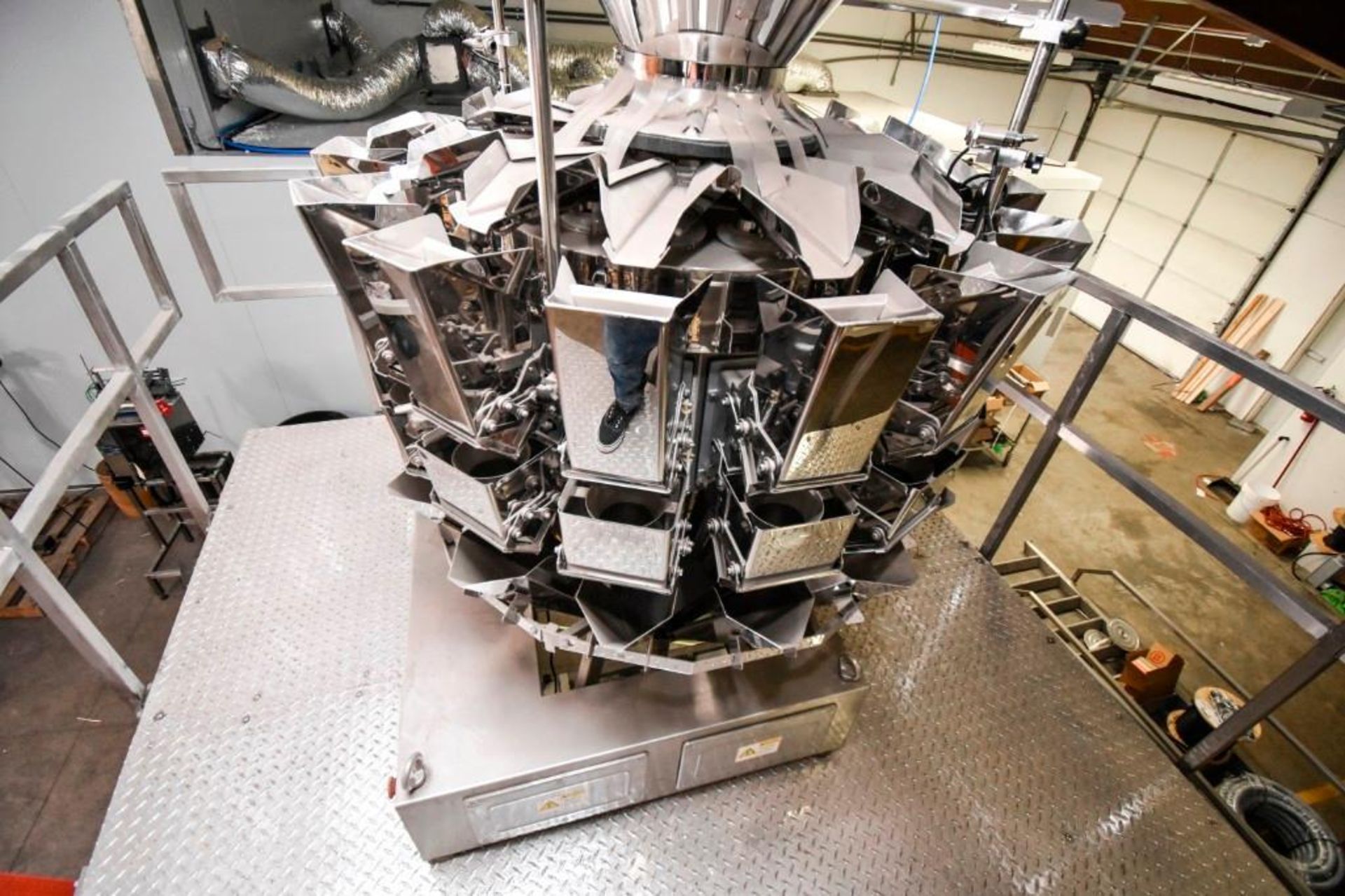

14 Head Combination Scale

Machine height: 1300 mm / 51″

Machine width: 1200 mm / 47.2”

Machine length: 1700 mm / 67″

Machine Weight: 500Kg / 1102 lbs

Weighing Accuracy: 0.5 grams

Electrical power supply: AC single phase 220V/60 Hz

Power consumption: 2.5 KW

Bag Width: 100mm – 300 mm

Bag Length: 130 mm – 320 mm

Power: 220 Volt, 1 Phase, 15 amps

Air 15-20 CFM @87 PSI

Key Features:

- Circular Arc Corner machine frame

- Independent control for each weighing head

- Intelligent multisampling for accurate weighing

- Intelligent fault alarm for easy maintenance

- CAN bus technology for faster processing

- Stainless Steel (#304) Construction, Food Safe

- 9” LCD Touch Screen

- Precise and Ultra-Fast Stepper motors

- Noise Filtering System

- Extremely accurate load cells

- Spring-less buckets for smoother and quieter operation

- Robust Housing for Stepper Motors

- Digital load cells weighing module

- Automatic cyclical or specified zeroing

- Multiple Dumps to maximize production Speed

- Digital load cells weighing module

- Automatic cyclical or specified zeroing

- Multiple Dumps to maximize production Speed

- Error Free Weighing Controls

- Flexibility to adjust control variables

- 3.0 Liter Bucket Volume

- Customized guided Discharge chutes

- Pre-programmed for up to 50 different weighs for various products

- Self Diagnostic feature helps troubleshoot any operational problems

- Single Touch Quick emptying of the Scale

- Single Touch Zeroing of all buckets

- Soft Calibration of the Load Cells

- Displays product level on the scale on Running Screen

- On-Screen Help Menu

General Information:

The 14-head scale is a single discharge multi-head combination net weigher ideal for weighing or counting a wide range of products including confectionery, bakery, pet food or treats, pasta, cereal, charcoal, fresh produce, and salty snacks up to 110 discharges per minute.

Applications:

Sticky products

Fresh meat and fish, whether in a sauce or not, poultry, and cheese (including grated cheese) can be moved along by using belts or screw feeders rather than vibration.

Granules and powders

While free-flowing, fine-grained powders can be weighed more cheaply by other means (such as cut-gate or linear weighers, or volumetric feeders), granules such as coffee granules and products such as loose tea can be weighed on today’s multi heads.

Fragile products

Weighers with more shallow angles of descent and various cushioned inserts have made it possible to pack delicate and brittle items such as hand-made chocolates and gourmet biscuits. These are often paired with baggers or other packaging systems designed to handle fragile products.

Complex products

Using mix-weighing combined with a distribution system tailored to deliver separate components into a tray, a ready meal can be assembled with just the right quantities of, say, rice, meat, and vegetables in the appropriate compartments.

Includes 2 APPE DOY 100 Pouch Filling Machine

Product Principal Features

- Ideal for Stand up Pouches of various forms and sizes

- Solid Stainless Steel Structure

- PLC Controlled machine with touch screen HMI Screen

- Speeds ranging from 15 – 20 bags/ min

- Automatically picks the bag from the magazine and open it under the filler

- 300 pouches holding capacity magazine

- Bags can be loaded while the machine in operation, safe and easy load

- Multiple bag detection sensors placed at various points of the cycle to ensure correct bag placement and accuracy

- Auto Stop and Alarm at the event of defected bag detection or misalignment

- Pouches are removed from the magazine with a unique combination of vacuum and pneumatic actuators. Actuators are rotated to the fill area and opened.

- During filling, pouches are held in place with our POSI HOLD gripper system which allows for heavy weight s and shock loads with our disturbing the position of the bag.

- Strong pneumatic finger gripping to hold the bag firmly

- Digitally controlled ribbed or flat constant heat seal bars give an attractive seal to the finished bag.

- Pouches are sealed in place eliminating wrinkles, folded corners & Mis-aligned seals.

- The transition bucket receives the product from the filler, opens the mouth of the bag, and dispenses the product inside the bag.

- Sanitary design for easy cleaning.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Quitman, Texas

Load Out: $4524

Skidding: $884

1 Used 14 Head Scale with 2 APPE DOY 100 Pouch Filling Machine

Standard Technical Data

14 Head Combination Scale

Machine height: 1300 mm / 51″

Machine width: 1200 mm / 47.2”

Machine length: 1700 mm / 67″

Machine Weight: 500Kg / 1102 lbs

Weighing Accuracy: 0.5 grams

Electrical power supply: AC single phase 220V/60 Hz

Power consumption: 2.5 KW

Bag Width: 100mm – 300 mm

Bag Length: 130 mm – 320 mm

Power: 220 Volt, 1 Phase, 15 amps

Air 15-20 CFM @87 PSI

Key Features:

- Circular Arc Corner machine frame

- Independent control for each weighing head

- Intelligent multisampling for accurate weighing

- Intelligent fault alarm for easy maintenance

- CAN bus technology for faster processing

- Stainless Steel (#304) Construction, Food Safe

- 9” LCD Touch Screen

- Precise and Ultra-Fast Stepper motors

- Noise Filtering System

- Extremely accurate load cells

- Spring-less buckets for smoother and quieter operation

- Robust Housing for Stepper Motors

- Digital load cells weighing module

- Automatic cyclical or specified zeroing

- Multiple Dumps to maximize production Speed

- Digital load cells weighing module

- Automatic cyclical or specified zeroing

- Multiple Dumps to maximize production Speed

- Error Free Weighing Controls

- Flexibility to adjust control variables

- 3.0 Liter Bucket Volume

- Customized guided Discharge chutes

- Pre-programmed for up to 50 different weighs for various products

- Self Diagnostic feature helps troubleshoot any operational problems

- Single Touch Quick emptying of the Scale

- Single Touch Zeroing of all buckets

- Soft Calibration of the Load Cells

- Displays product level on the scale on Running Screen

- On-Screen Help Menu

General Information:

The 14-head scale is a single discharge multi-head combination net weigher ideal for weighing or counting a wide range of products including confectionery, bakery, pet food or treats, pasta, cereal, charcoal, fresh produce, and salty snacks up to 110 discharges per minute.

Applications:

Sticky products

Fresh meat and fish, whether in a sauce or not, poultry, and cheese (including grated cheese) can be moved along by using belts or screw feeders rather than vibration.

Granules and powders

While free-flowing, fine-grained powders can be weighed more cheaply by other means (such as cut-gate or linear weighers, or volumetric feeders), granules such as coffee granules and products such as loose tea can be weighed on today’s multi heads.

Fragile products

Weighers with more shallow angles of descent and various cushioned inserts have made it possible to pack delicate and brittle items such as hand-made chocolates and gourmet biscuits. These are often paired with baggers or other packaging systems designed to handle fragile products.

Complex products

Using mix-weighing combined with a distribution system tailored to deliver separate components into a tray, a ready meal can be assembled with just the right quantities of, say, rice, meat, and vegetables in the appropriate compartments.

Includes 2 APPE DOY 100 Pouch Filling Machine

Product Principal Features

- Ideal for Stand up Pouches of various forms and sizes

- Solid Stainless Steel Structure

- PLC Controlled machine with touch screen HMI Screen

- Speeds ranging from 15 – 20 bags/ min

- Automatically picks the bag from the magazine and open it under the filler

- 300 pouches holding capacity magazine

- Bags can be loaded while the machine in operation, safe and easy load

- Multiple bag detection sensors placed at various points of the cycle to ensure correct bag placement and accuracy

- Auto Stop and Alarm at the event of defected bag detection or misalignment

- Pouches are removed from the magazine with a unique combination of vacuum and pneumatic actuators. Actuators are rotated to the fill area and opened.

- During filling, pouches are held in place with our POSI HOLD gripper system which allows for heavy weight s and shock loads with our disturbing the position of the bag.

- Strong pneumatic finger gripping to hold the bag firmly

- Digitally controlled ribbed or flat constant heat seal bars give an attractive seal to the finished bag.

- Pouches are sealed in place eliminating wrinkles, folded corners & Mis-aligned seals.

- The transition bucket receives the product from the filler, opens the mouth of the bag, and dispenses the product inside the bag.

- Sanitary design for easy cleaning.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Quitman, Texas

Load Out: $4524

Skidding: $884

INW / Protec Laboratories Surplus Equipment Auction

Ends from

General delivery information available from the auctioneer

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Important Information

IMPORTANT INFORMATION

AUCTION DATE:

LOTs start closing on Thursday, October 29th, 10:00 am PDT

LOCATION: Quitman, Texas

PICKUP: TBD

RIGGING:

There is no self-rigging. All Rigging and Loadout will be completed by a contracted and approved Rigger.

INSPECTION DATES: the 27th of October one day only!!!!, 818-495-3038

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com