50

Baker Perkins Modular Toffee and Caramel Cooker

1 Used Baker Perkins Modular Toffee and Caramel Cooker

Toffee Plant Introduction:

The toffee plant is built up of various elements that give it a great deal of flexibility. Elements can be readily added or taken away from the plant specification to give the most economic configuration. The elements built into a plant will depend upon the output, the evaporation load, and the total cooking or caramelizing time required.

The system incorporates dissolvers, cookers, and caramelizers. they can be arranged to:

a) Simultaneously cook and caramelize the premix to the desired moisture content and required color and flavor.

b) Pre-heat the pre-mix to remove some of the moisture and then simultaneously cook and caramelize to the desired moisture content and the required color and flavor.

c) Evaporate the majority of the moisture and then carry out the final cooking to the required moisture content together with the caramelization to the desired color and flavor.

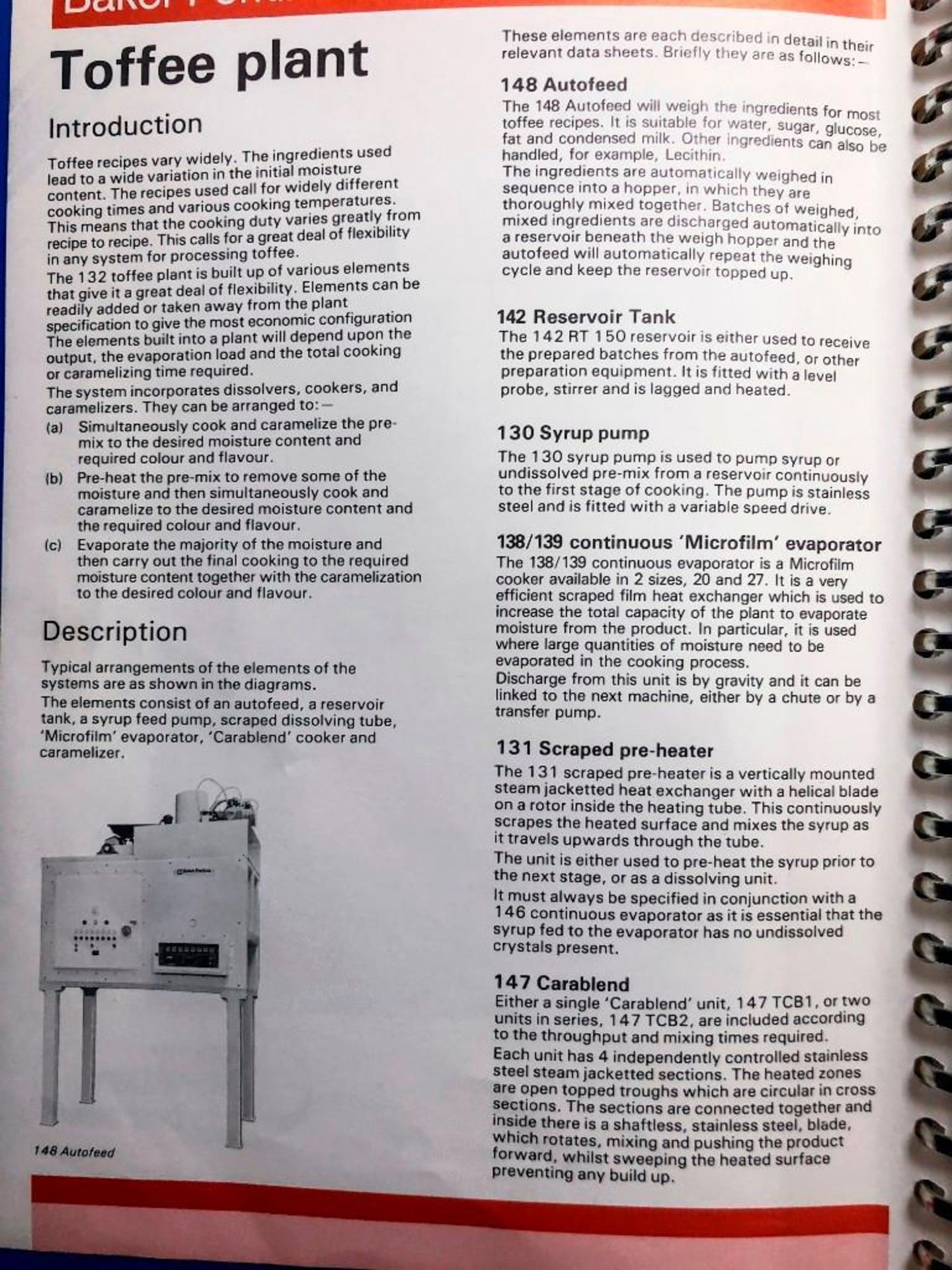

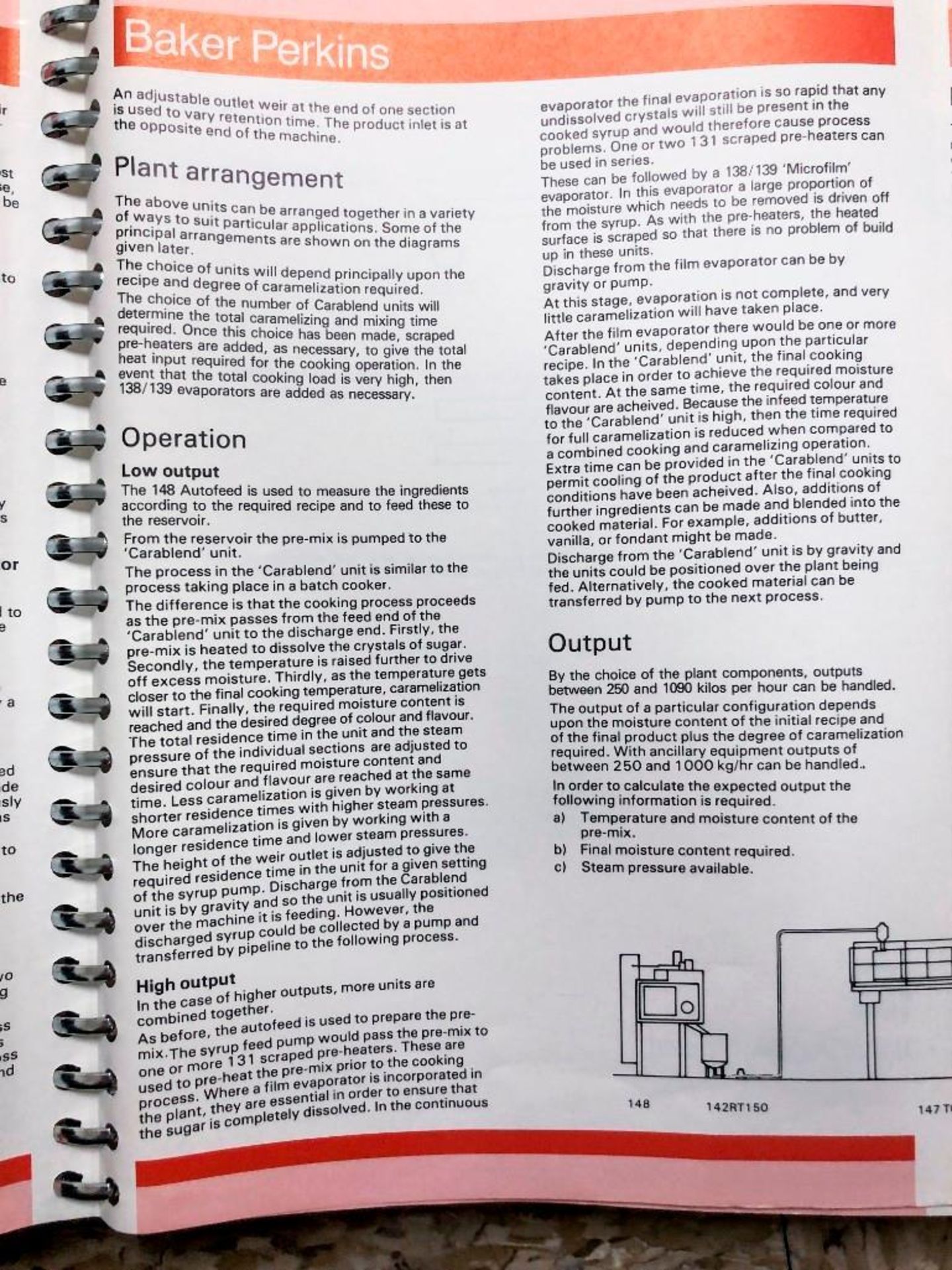

Arrangements:

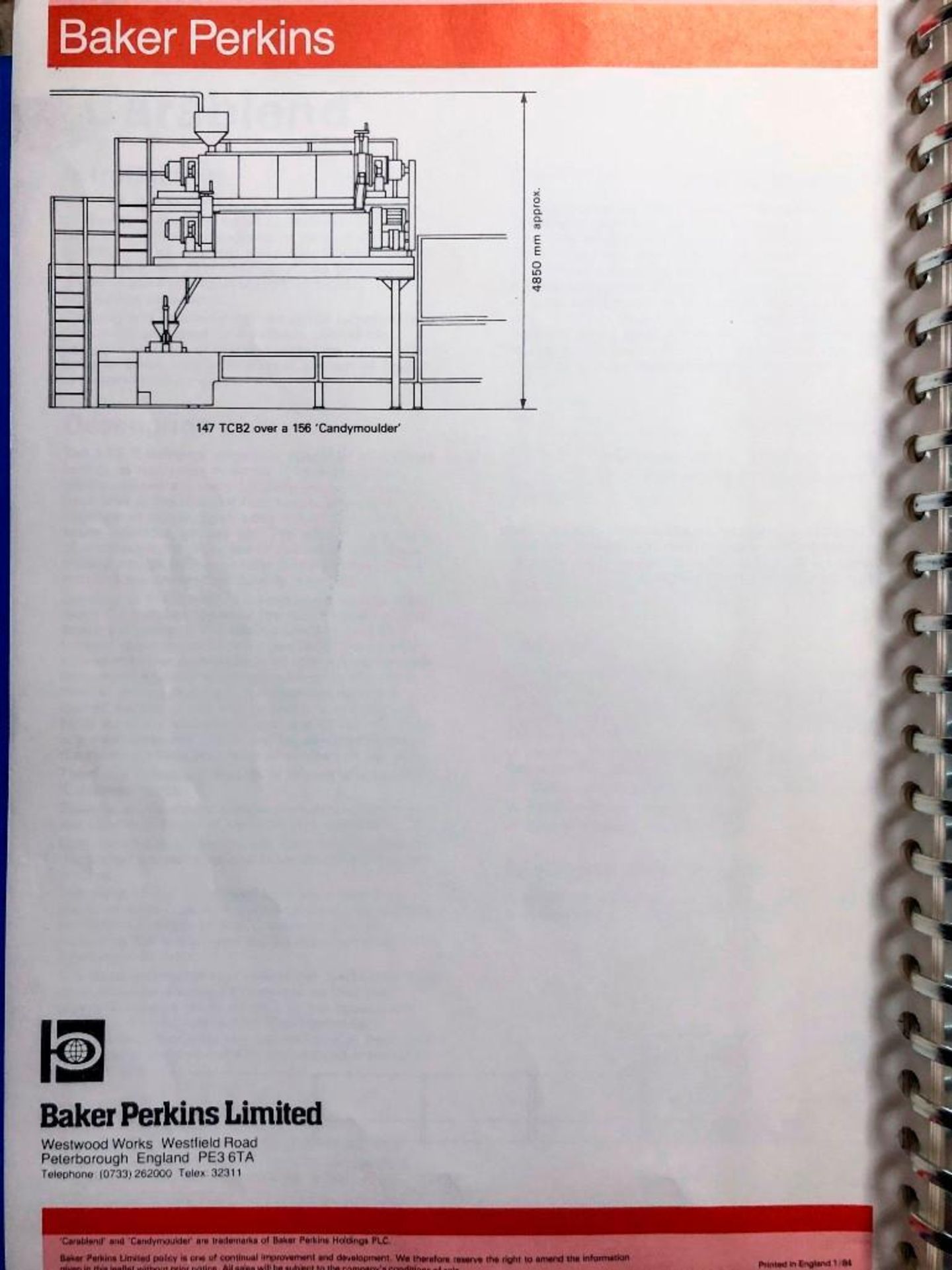

Typical arrangements of the elements of the systems are as shown in the diagrams. The elements consist of:

- An Autofeed

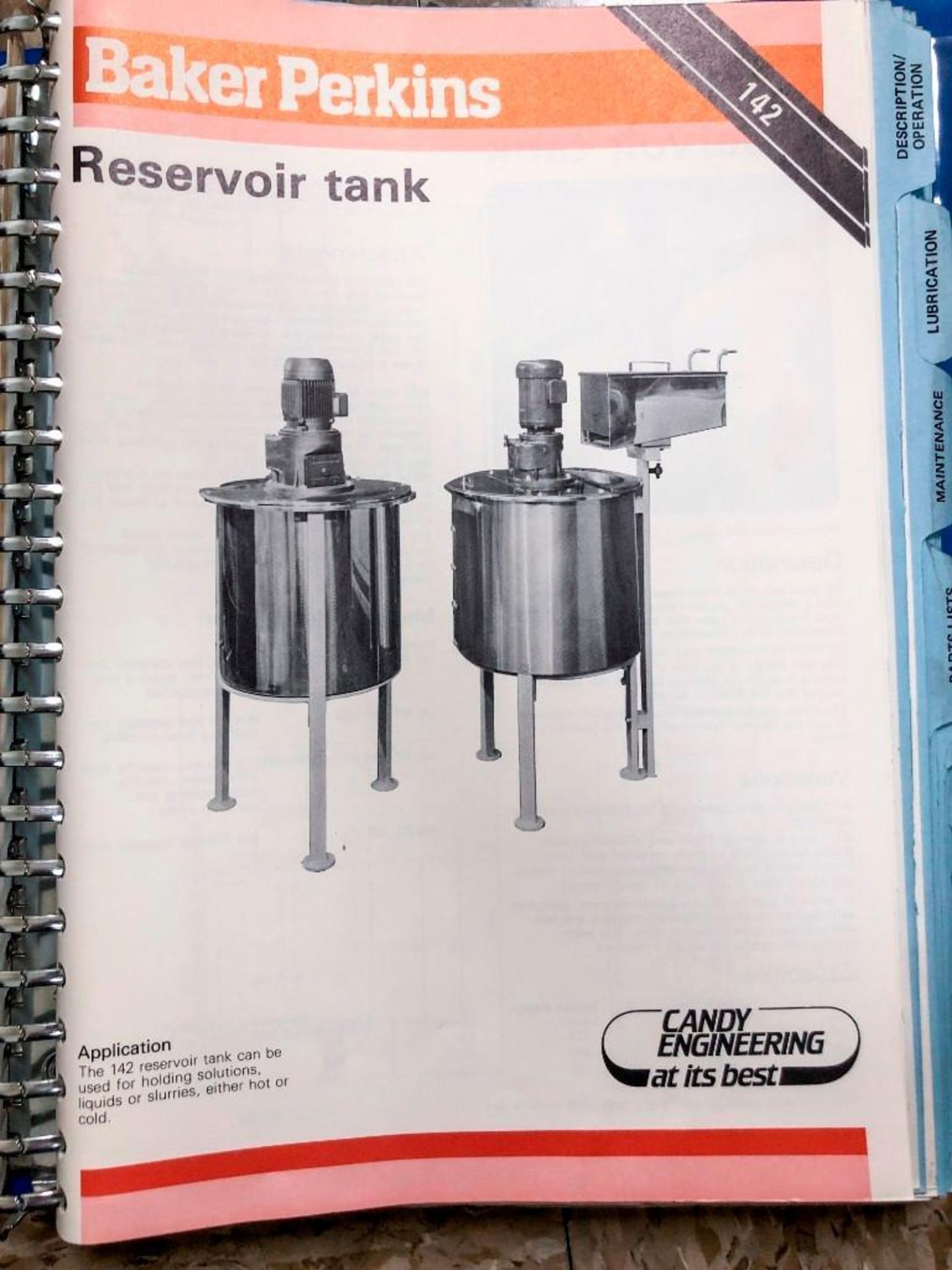

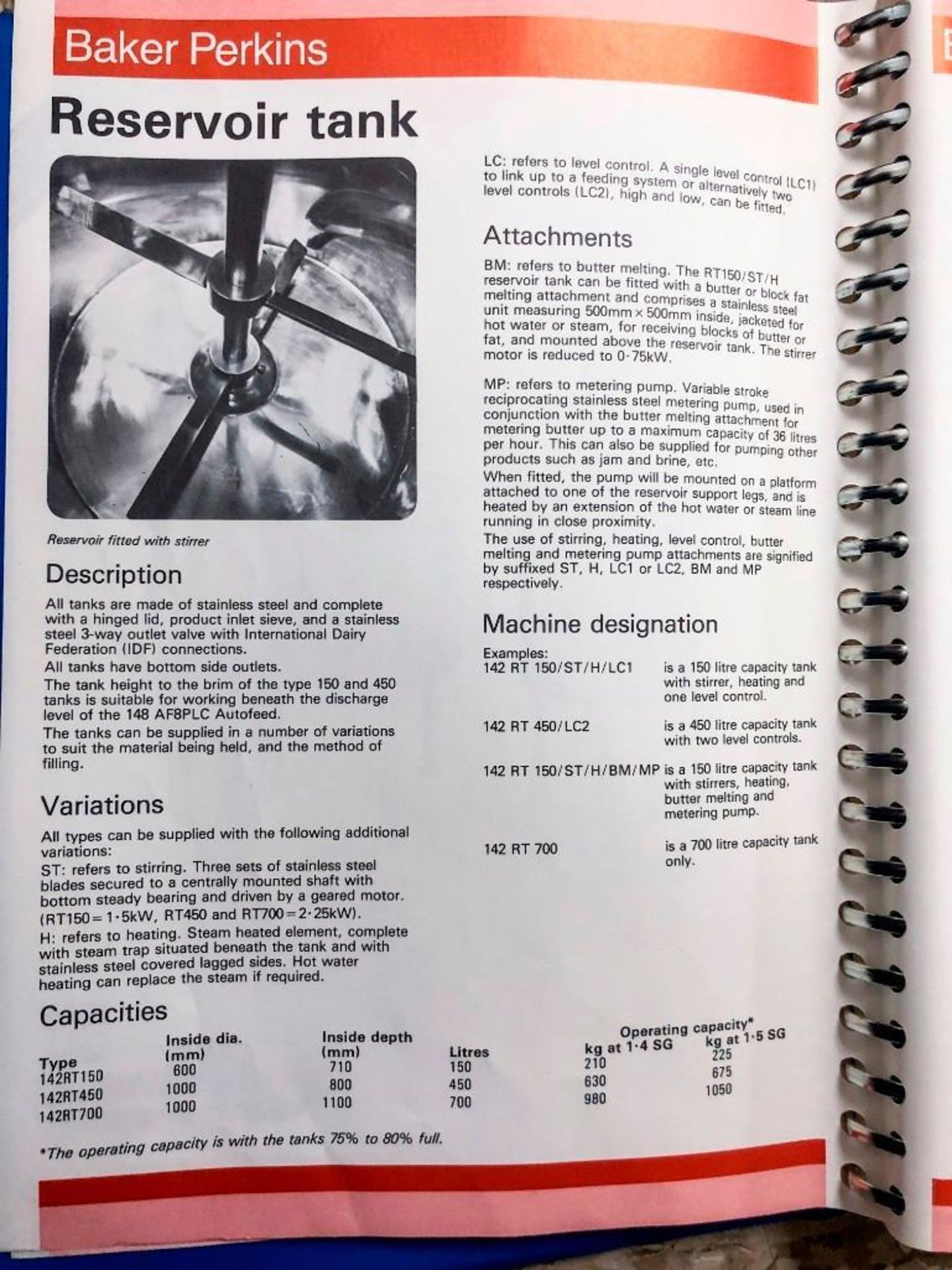

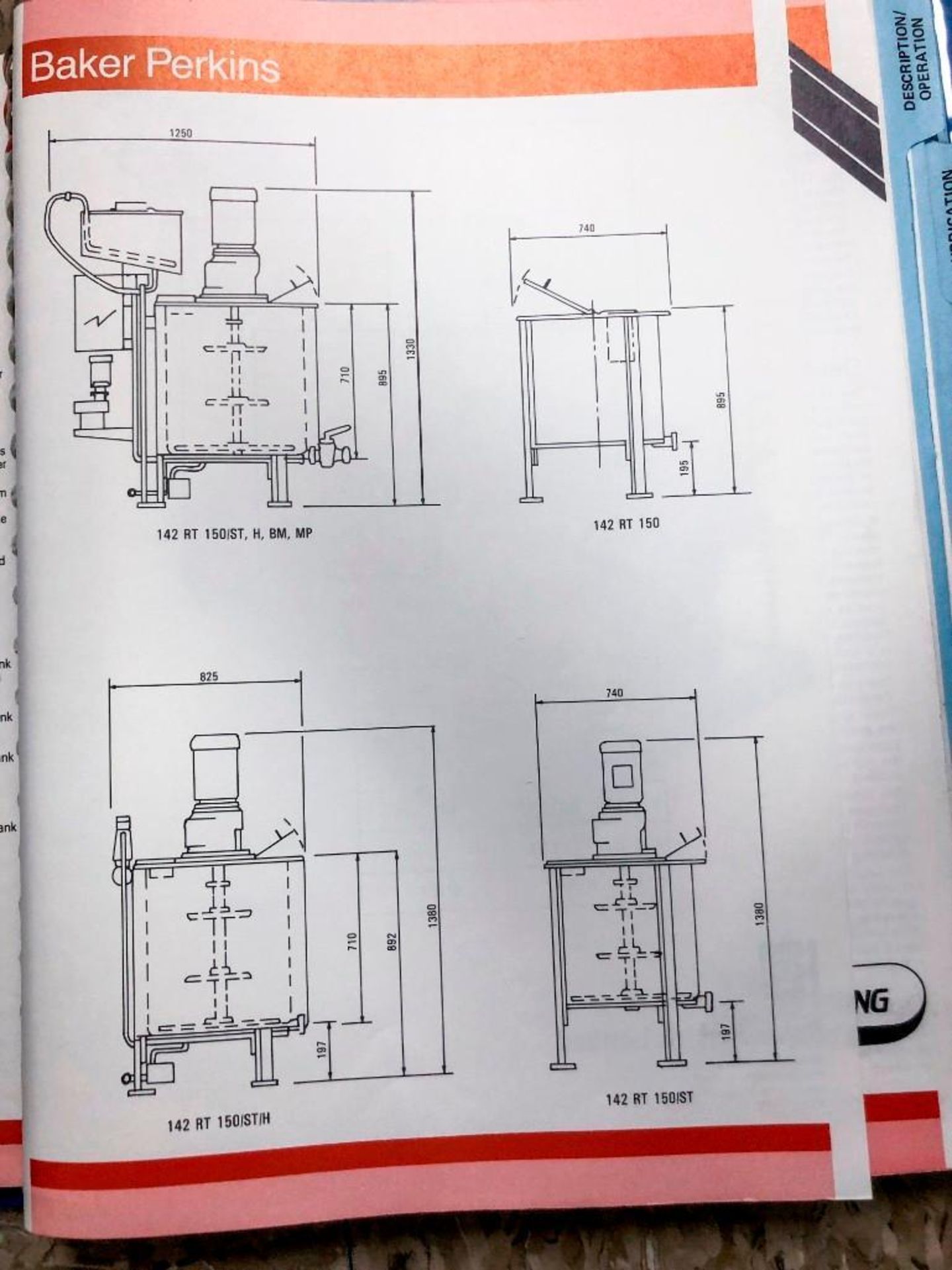

- A Reservoir tank

- Syrup Feed Pump

- Scraped Dissolving Tube

- Microfilm Evaporator

- Carablend cooker

- Caramelizer

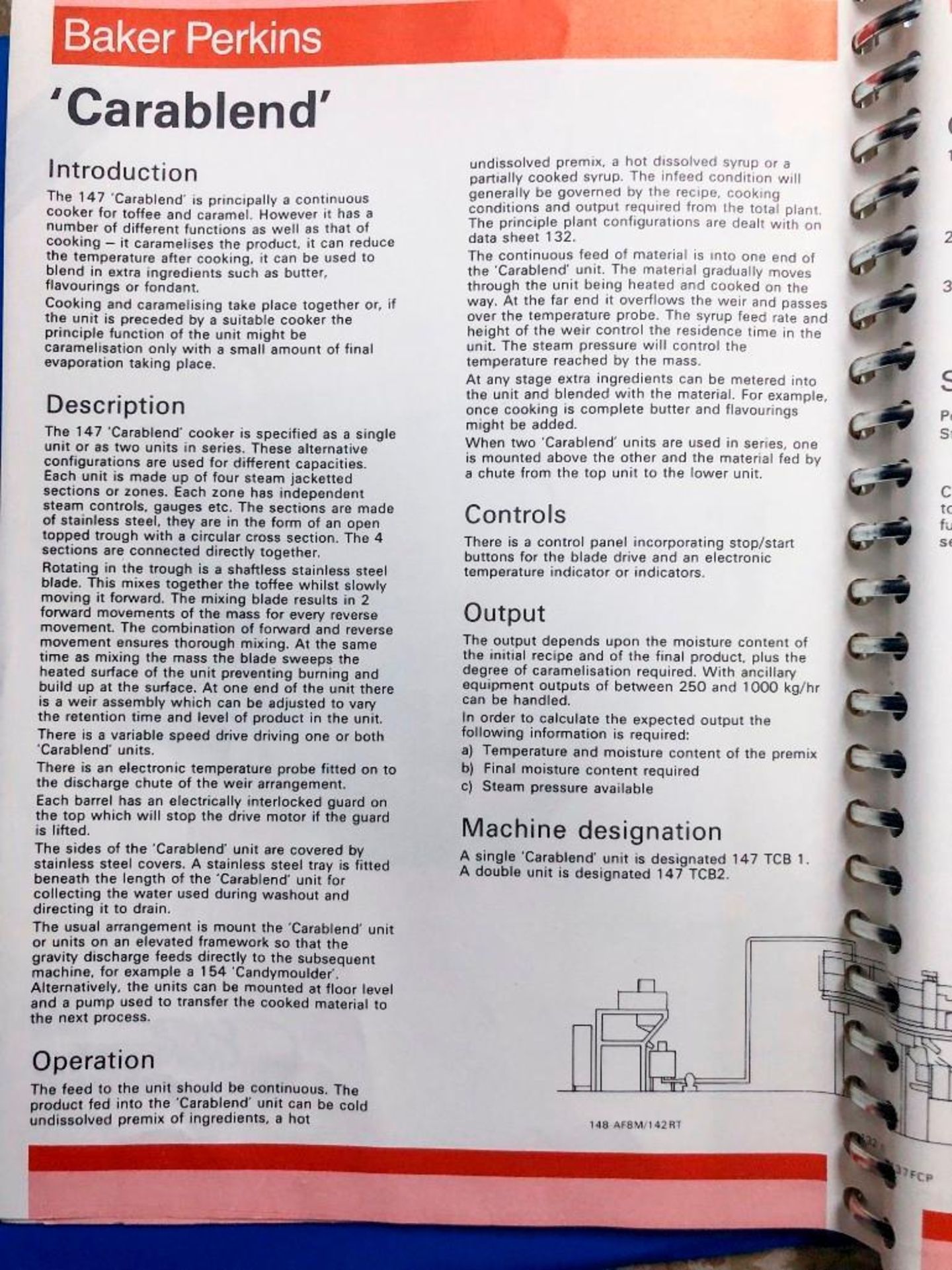

Carablend Info:

The Carablend is principally a continuous cooker for toffee and caramel. However, it has a number of different functions as well as that of cooking. It caramelizes the product, it can reduce the temperature after cooking it can be used to blend in extra ingredients such as butter, flavorings, or fondant. Cooking and caramelizing take place together or, if the unit is preceded by a suitable cooker the principal function of the unit might be caramelization only with a small amount of final evaporation taking place.

The Carablend is specified as a single unit or as two units in series. These alternative configurations are used for different capacities.

- Each unit is made up of four steam jacketed sections or zones. Each zone has independent steam controls. The sections are made of stainless steel, they are in the form of an open-topped trough with a circular cross-section. The 4 sections are connected directly together.

- Rotating in the trough is a shaftless stainless steel blade. This mixes together the toffee whilst slowly moving it forward. The mixing blade results in 2 forward movements of the mass for every reverse movement. The combination of forward and reverse movement ensures thorough mixing. At the same time as mixing the mass, the blade sweeps the heated surface of the unit preventing burning and build up at the surface.

- There is a variable speed drive driving one or both Carablend units

- There is an electronic temperature probe fitted on to the discharge chute of the weir arrangement.

- Each barrel has an electrically interlocked guard on the top which will stop the drive motor if the guard is lifted.

- The sides of the Carablend unit are covered with stainless steel covers. A stainless steel tray is fitted beneath the length of the Carablend unit for collecting the water used during washout and directing it to drain.

- The usual arrangement is to mount the Carablend unit or units on an elevated framework so that the gravity discharge feeds directly to the subsequent machine. Alternatively, the units can be mounted at floor level and a pump used to transfer the cooked material to the next process.

Scraped Pre-Heat Info:

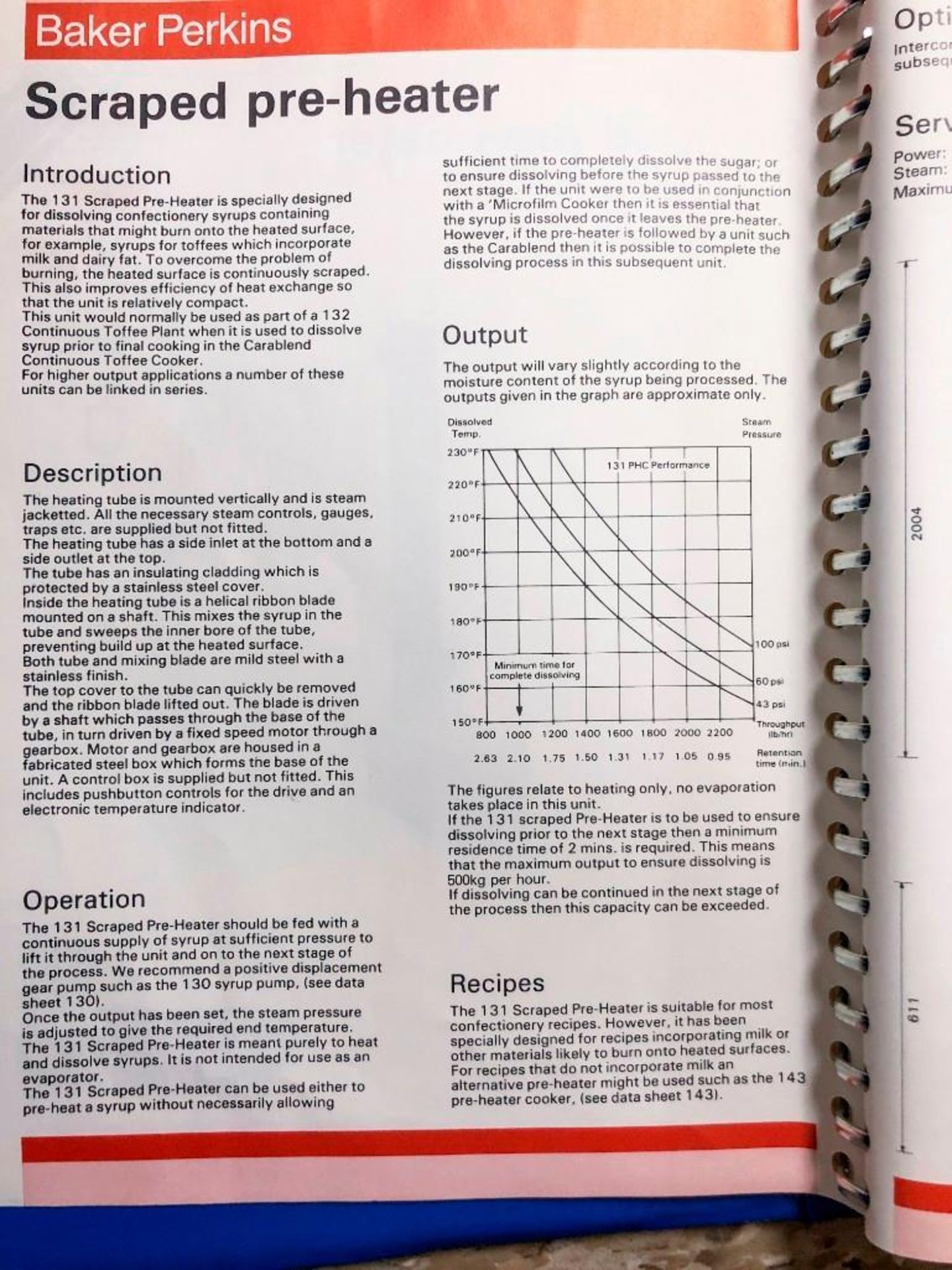

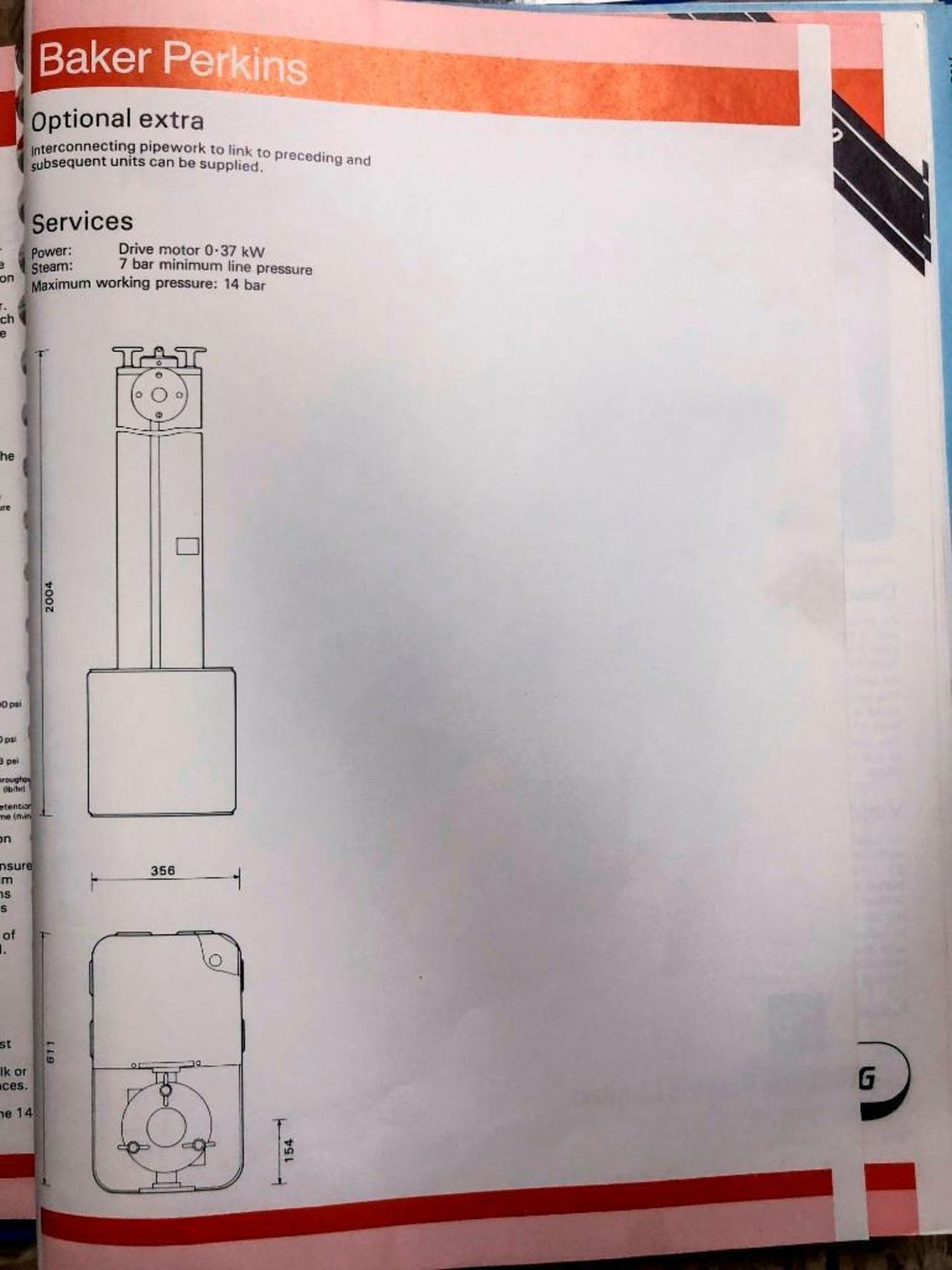

The Scraped Pre-Heater is specially designed for dissolving confectionery syrups containing materials that might burn onto the heated surface, for example, syrups for toffees which incorporate milk and dairy fats. To overcome the problem of burning, the heated surface is continuously scraped. This also improves the efficiency of heat exchange so that the unit is relatively compact.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Gardena, CA

Load Out: $3250

Skidding: $0

Category: Chocolate, Caramel, Nuts, Nut, Peanuts, Macadamian, Candy, Sweets, Cookie, Treat, Confectionary, Cooking, Bakery, Dessert, Mold, Hawaiian Host, Cake, Sweet

1 Used Baker Perkins Modular Toffee and Caramel Cooker

Toffee Plant Introduction:

The toffee plant is built up of various elements that give it a great deal of flexibility. Elements can be readily added or taken away from the plant specification to give the most economic configuration. The elements built into a plant will depend upon the output, the evaporation load, and the total cooking or caramelizing time required.

The system incorporates dissolvers, cookers, and caramelizers. they can be arranged to:

a) Simultaneously cook and caramelize the premix to the desired moisture content and required color and flavor.

b) Pre-heat the pre-mix to remove some of the moisture and then simultaneously cook and caramelize to the desired moisture content and the required color and flavor.

c) Evaporate the majority of the moisture and then carry out the final cooking to the required moisture content together with the caramelization to the desired color and flavor.

Arrangements:

Typical arrangements of the elements of the systems are as shown in the diagrams. The elements consist of:

- An Autofeed

- A Reservoir tank

- Syrup Feed Pump

- Scraped Dissolving Tube

- Microfilm Evaporator

- Carablend cooker

- Caramelizer

Carablend Info:

The Carablend is principally a continuous cooker for toffee and caramel. However, it has a number of different functions as well as that of cooking. It caramelizes the product, it can reduce the temperature after cooking it can be used to blend in extra ingredients such as butter, flavorings, or fondant. Cooking and caramelizing take place together or, if the unit is preceded by a suitable cooker the principal function of the unit might be caramelization only with a small amount of final evaporation taking place.

The Carablend is specified as a single unit or as two units in series. These alternative configurations are used for different capacities.

- Each unit is made up of four steam jacketed sections or zones. Each zone has independent steam controls. The sections are made of stainless steel, they are in the form of an open-topped trough with a circular cross-section. The 4 sections are connected directly together.

- Rotating in the trough is a shaftless stainless steel blade. This mixes together the toffee whilst slowly moving it forward. The mixing blade results in 2 forward movements of the mass for every reverse movement. The combination of forward and reverse movement ensures thorough mixing. At the same time as mixing the mass, the blade sweeps the heated surface of the unit preventing burning and build up at the surface.

- There is a variable speed drive driving one or both Carablend units

- There is an electronic temperature probe fitted on to the discharge chute of the weir arrangement.

- Each barrel has an electrically interlocked guard on the top which will stop the drive motor if the guard is lifted.

- The sides of the Carablend unit are covered with stainless steel covers. A stainless steel tray is fitted beneath the length of the Carablend unit for collecting the water used during washout and directing it to drain.

- The usual arrangement is to mount the Carablend unit or units on an elevated framework so that the gravity discharge feeds directly to the subsequent machine. Alternatively, the units can be mounted at floor level and a pump used to transfer the cooked material to the next process.

Scraped Pre-Heat Info:

The Scraped Pre-Heater is specially designed for dissolving confectionery syrups containing materials that might burn onto the heated surface, for example, syrups for toffees which incorporate milk and dairy fats. To overcome the problem of burning, the heated surface is continuously scraped. This also improves the efficiency of heat exchange so that the unit is relatively compact.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Gardena, CA

Load Out: $3250

Skidding: $0

Category: Chocolate, Caramel, Nuts, Nut, Peanuts, Macadamian, Candy, Sweets, Cookie, Treat, Confectionary, Cooking, Bakery, Dessert, Mold, Hawaiian Host, Cake, Sweet

Hawaiian Host

Ends from

PICKUP:

Pickup to begin on October 7th, 2020 after cleared by payment. All pickups must be complete by October 21st, 2020 at 1pm PDT or equipment will be considered abandoned.

RIGGING:

There is no self-rigging. All Rigging and Loadout will be completed by a contracted and approved Rigger.

Important Information

IMPORTANT INFORMATION

AUCTION DATE:

LOTs start closing on Thursday, October 1st, 10:00 am PDT

LOCATION:

Gardena, California

PICKUP:

Pickup to begin on October 7th, 2020 after cleared by payment. All pickups must be complete by October 21st, 2020 at 1pm PDT or equipment will be considered abandoned.

RIGGING:

There is no self-rigging. All Rigging and Loadout will be completed by a contracted and approved Rigger.

INSPECTION DATES

September 28nd, from 7am - 1pm PDT and September 29th, from 7am - 1pm PDT by Appointment Only. We are able to accomodate in-person or live video. Please email our Sales Department at sales@hillseth.com to schedule an appointment.

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com