107

PRINTER APPLICATOR LABELING SYSTEM & CONVEYOR

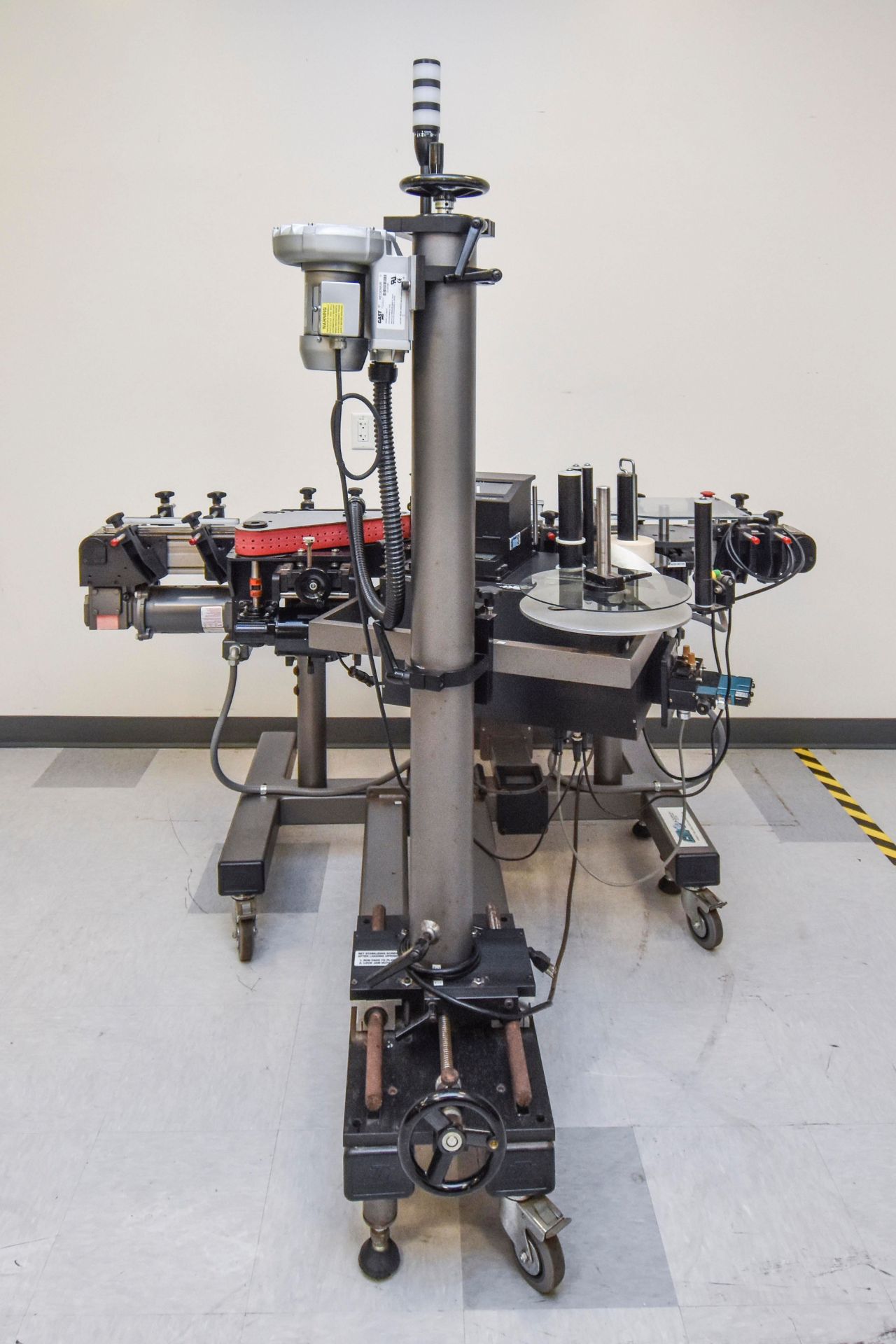

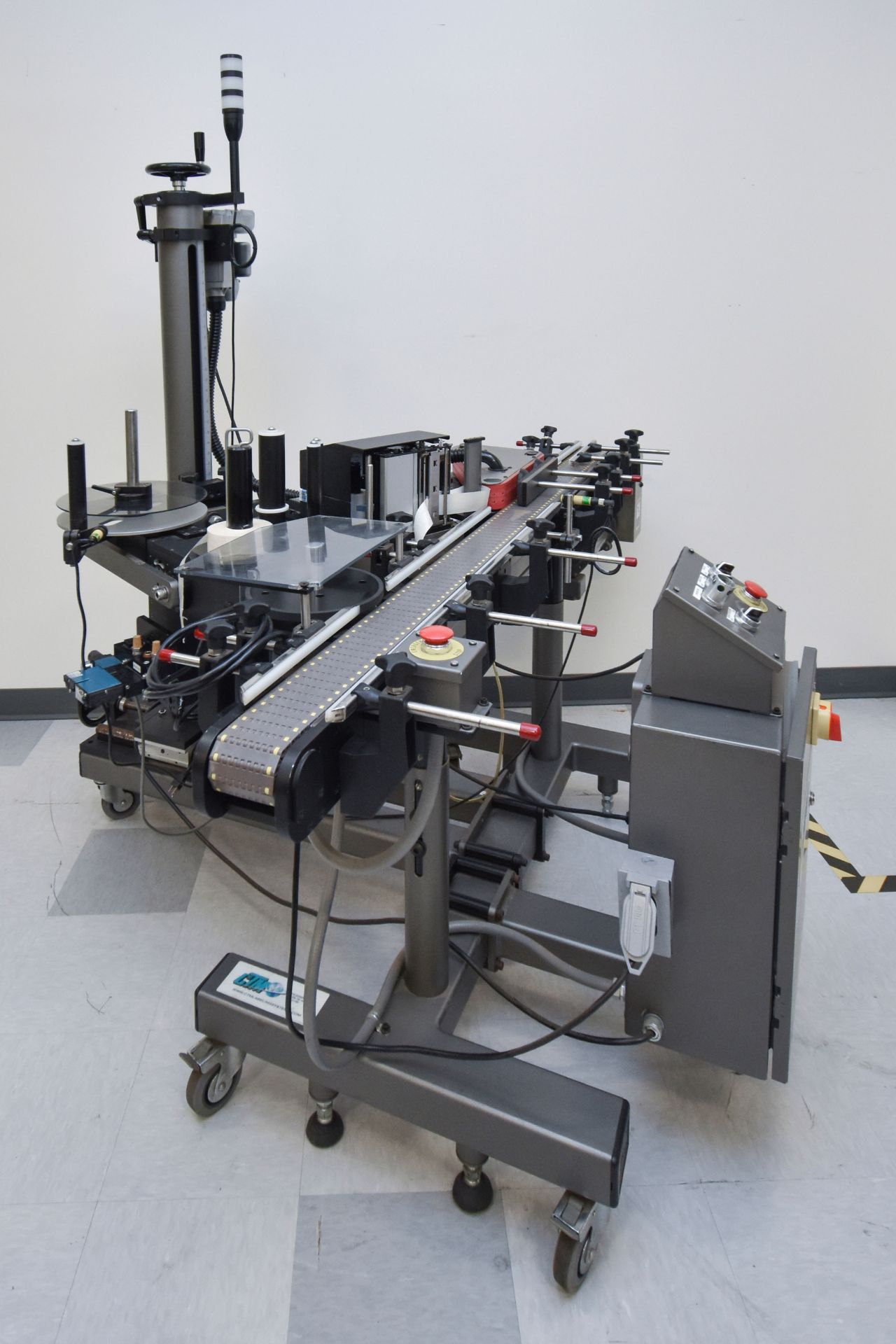

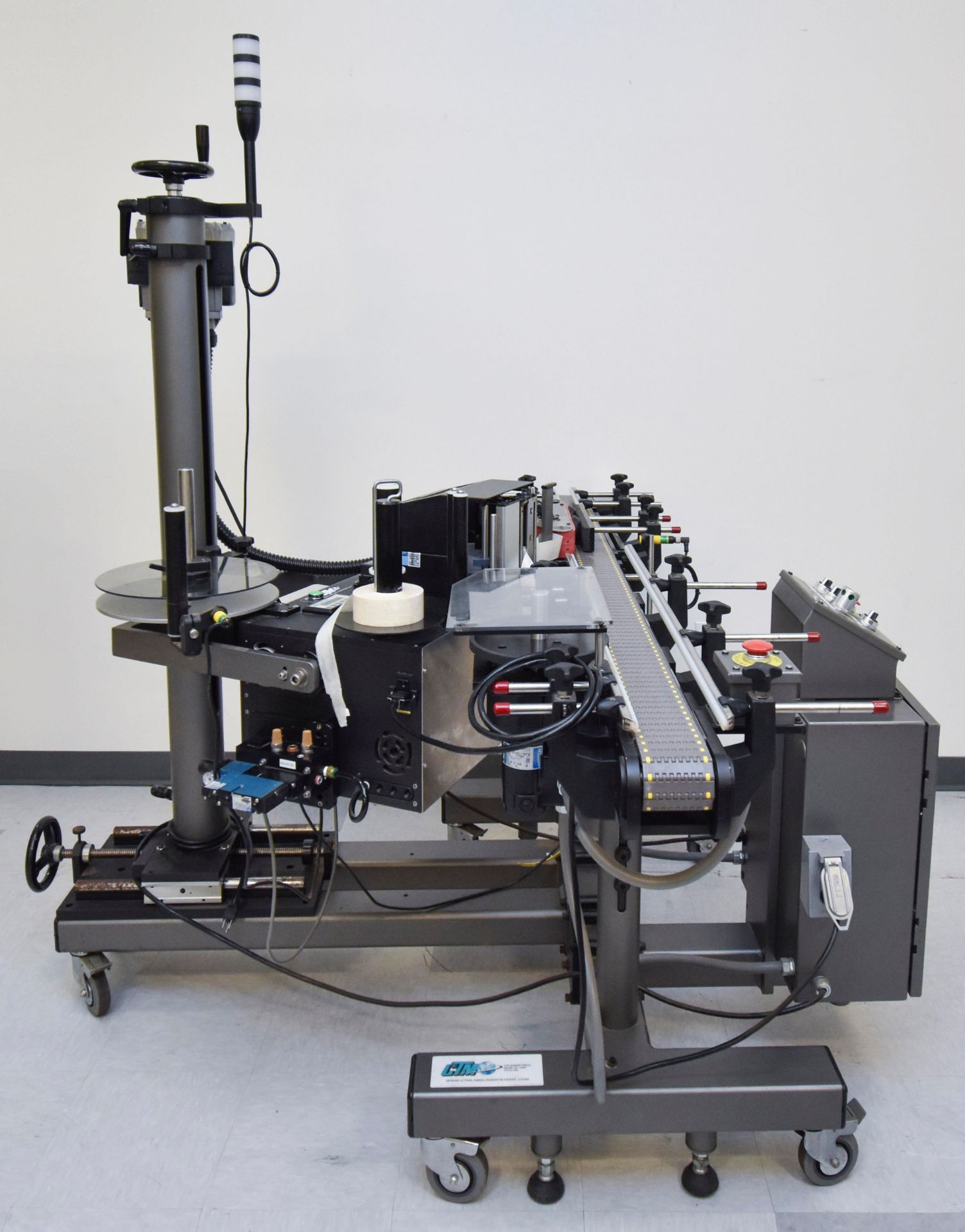

1-Used 360a-WR Wrap System With 1-Used CTM MDL: 3600-PA Printer Applicator Labeling System & Conveyor

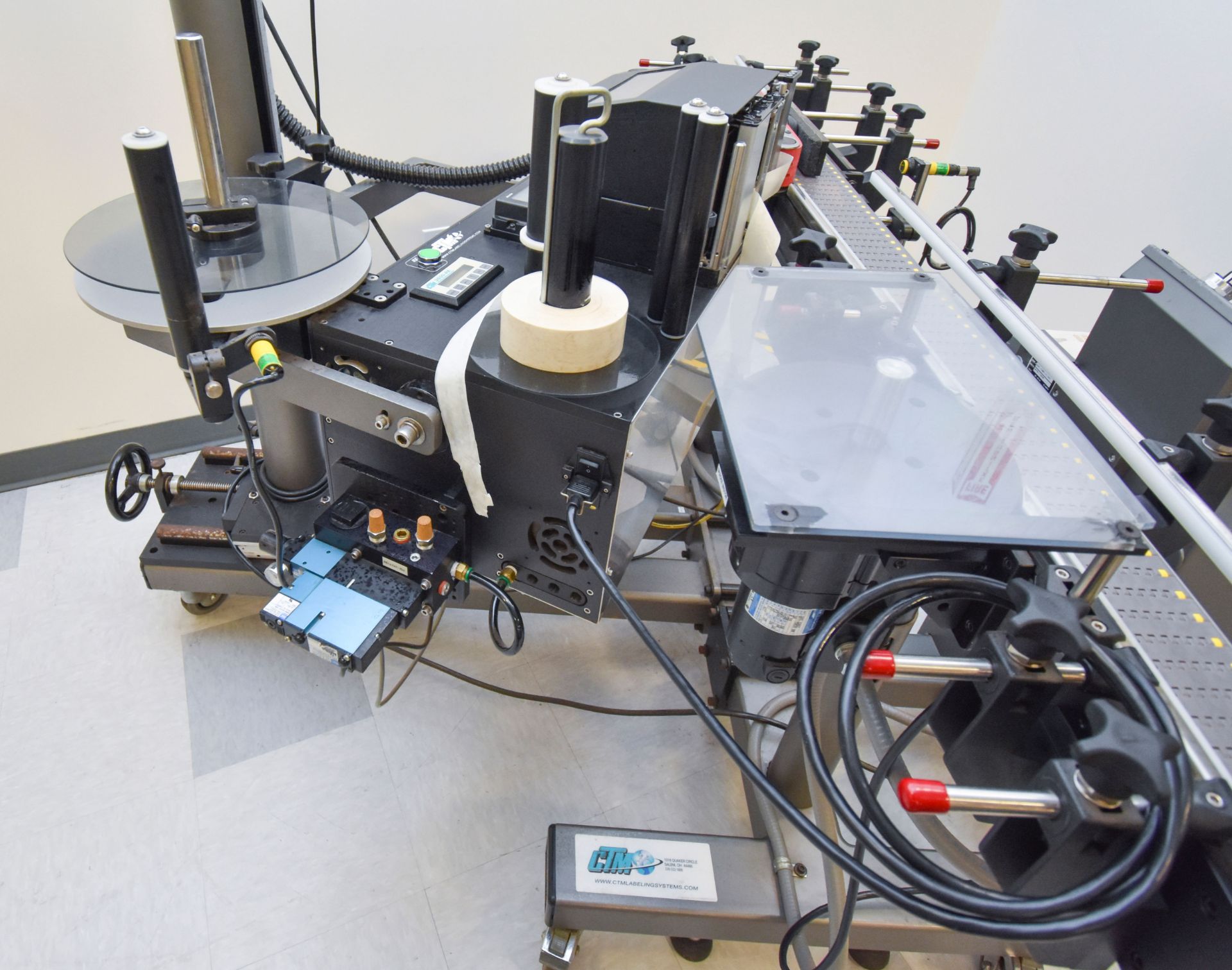

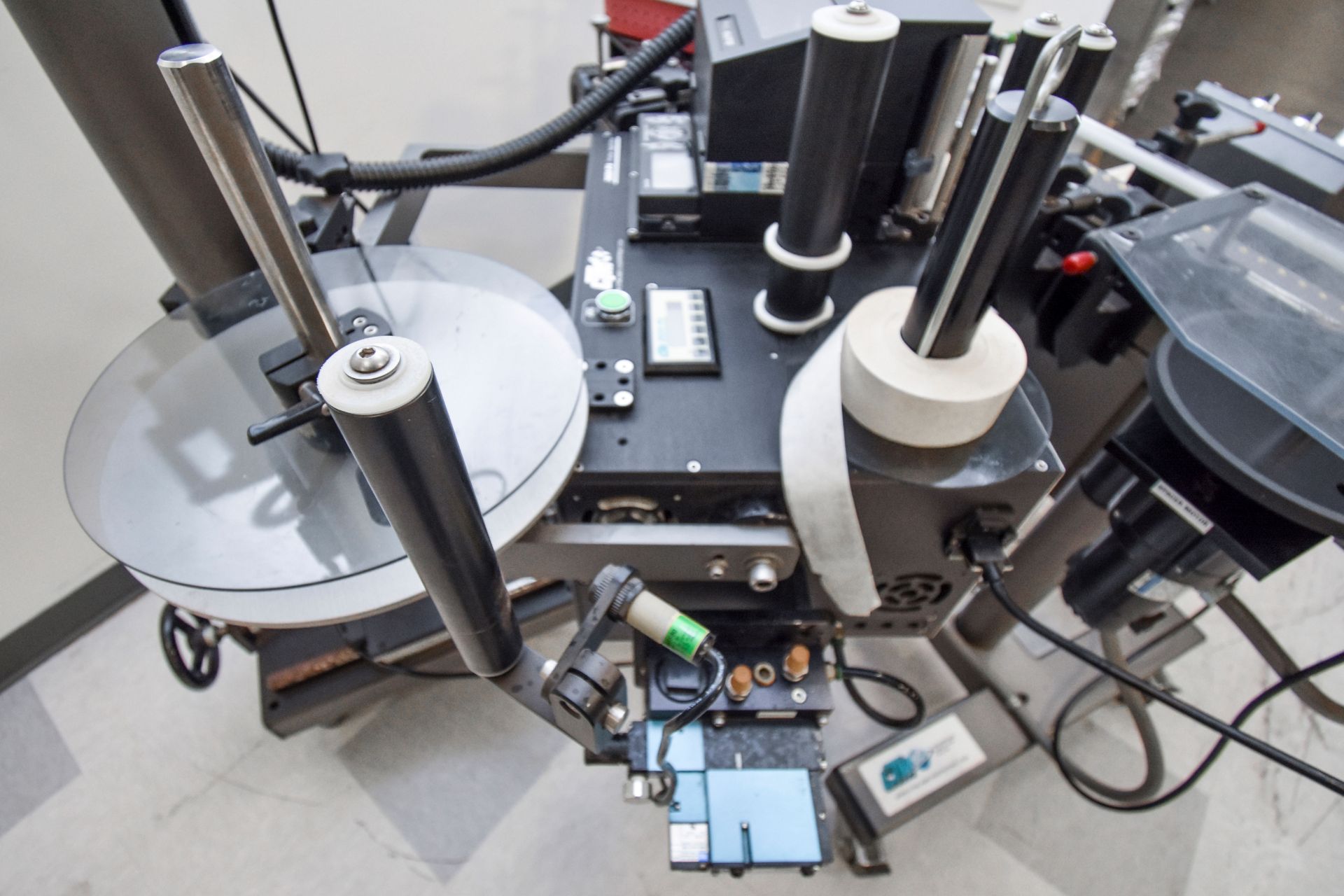

360a-WR Wrap System

Features:

For the cost conscious, low volume or entry level partners the

CTM 360a WR wrap labeling system provides the ideal way for

high quality round product labeling. It uses CTM’s advanced 360a

merge applicator with remote HMI operator touch screen color

display. The 360a is available in the 5" wide and 7-1/2" wide

versions accommodating nearly all applications. For multiple labels

the 360a has 48 label format storage for operator selection- no

need to re-calibrate the same labels.

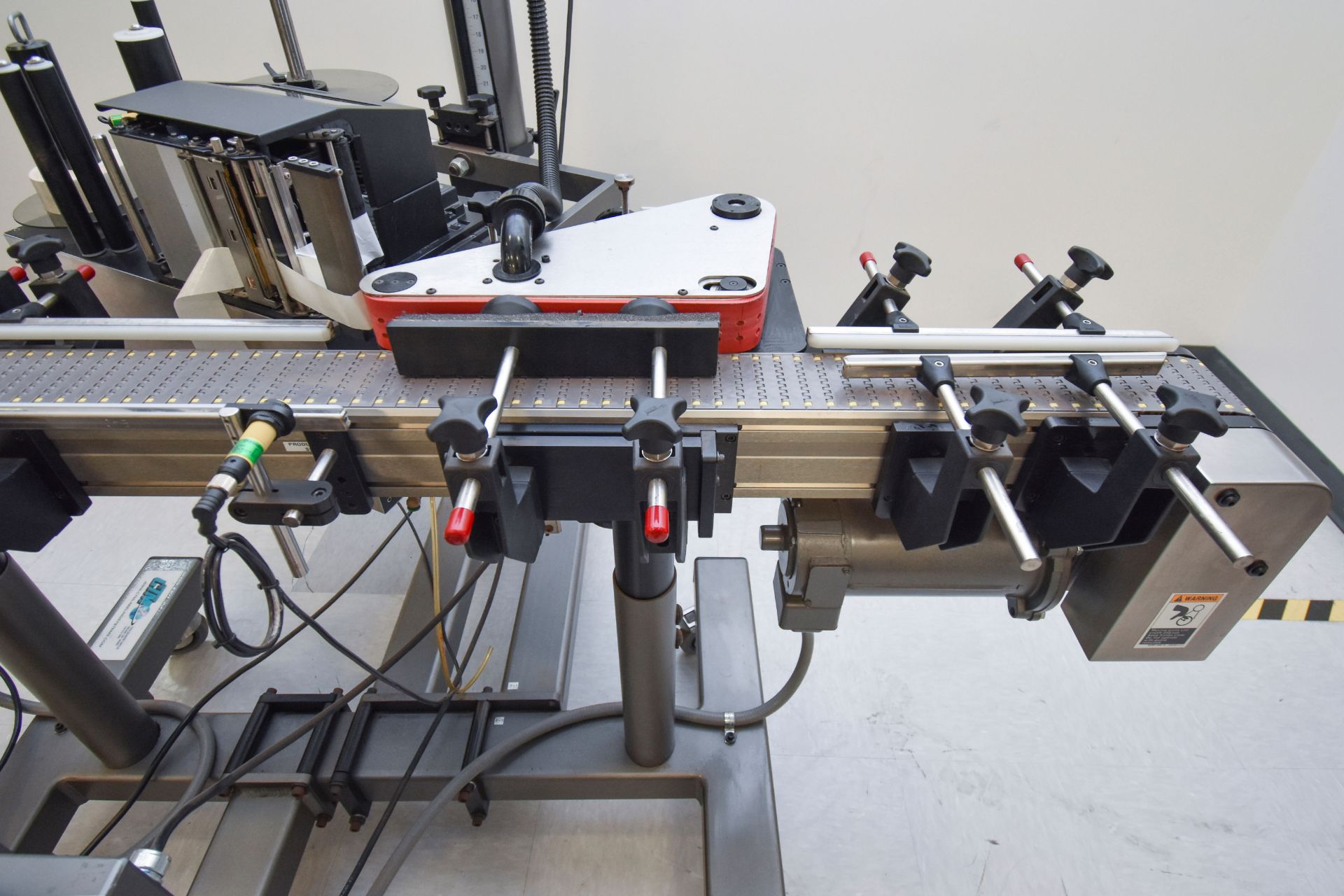

Compact and complete the unit measures a 4' x 4' square footprint

with the 6" wide x 4 ft. long conveyor, wrap belt assembly and ball

bushing traverse for the labeler. Independent speed adjustments

allow set ups for various product and label sizes and cycle rates.

The 360a WR system is provided only as a “build and ship” system

for economy.

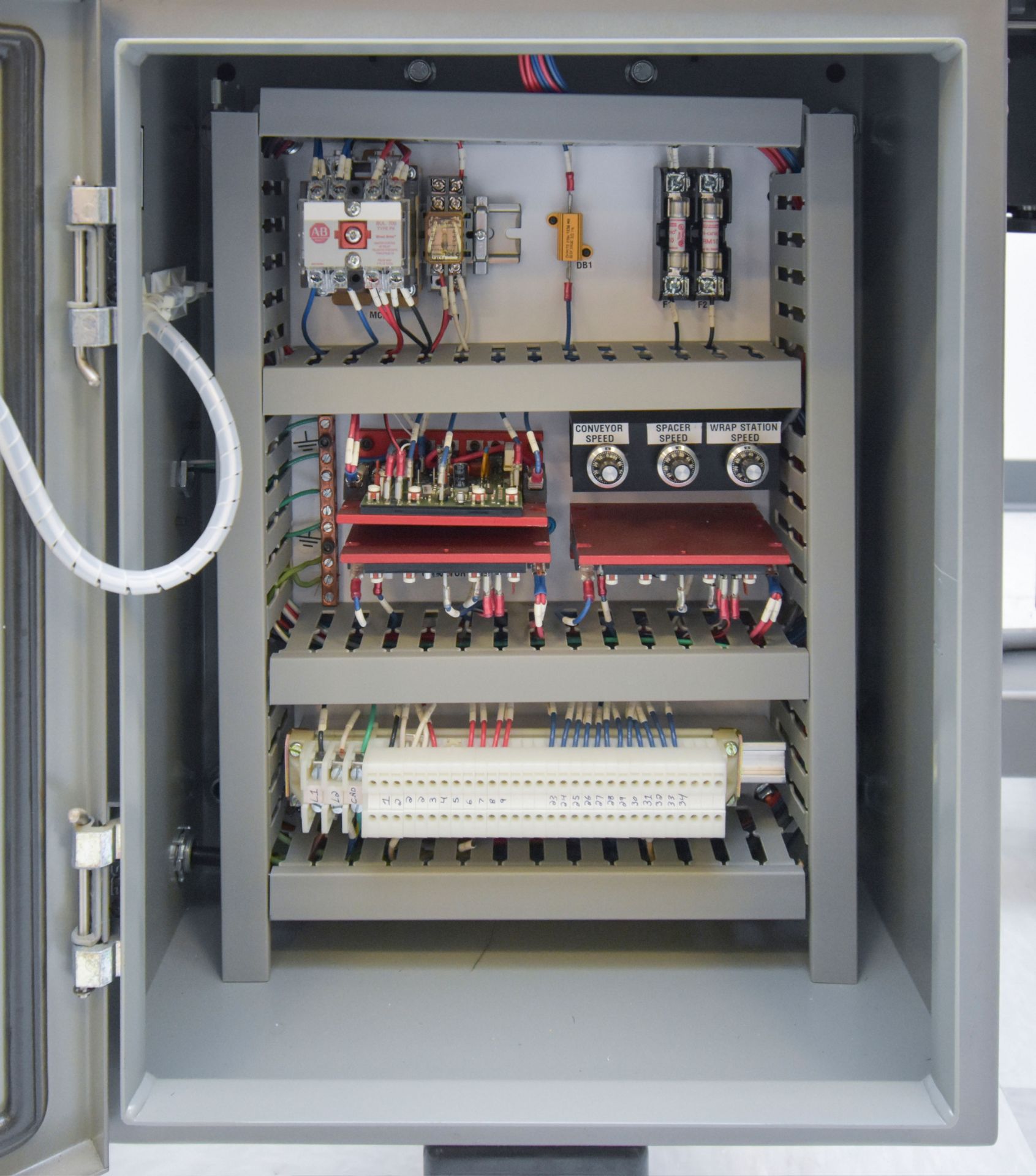

Electrical / Pneumatic:

108-132 Volts AC, 50/60 Hertz, Single Phase, 7 Amps.

Environmental:

Operating: 41° F to 104° F (5° C to 40° C)

Storage: -4° F to 105° F (-20° C to 40° C)

Optional Features:

Low label, Low Ribbon, End of Web, End of Ribbon

Stack light (silent or audible)

Consult CTM Labeling Systems for other options

Weight:

Approx. 700 lbs.

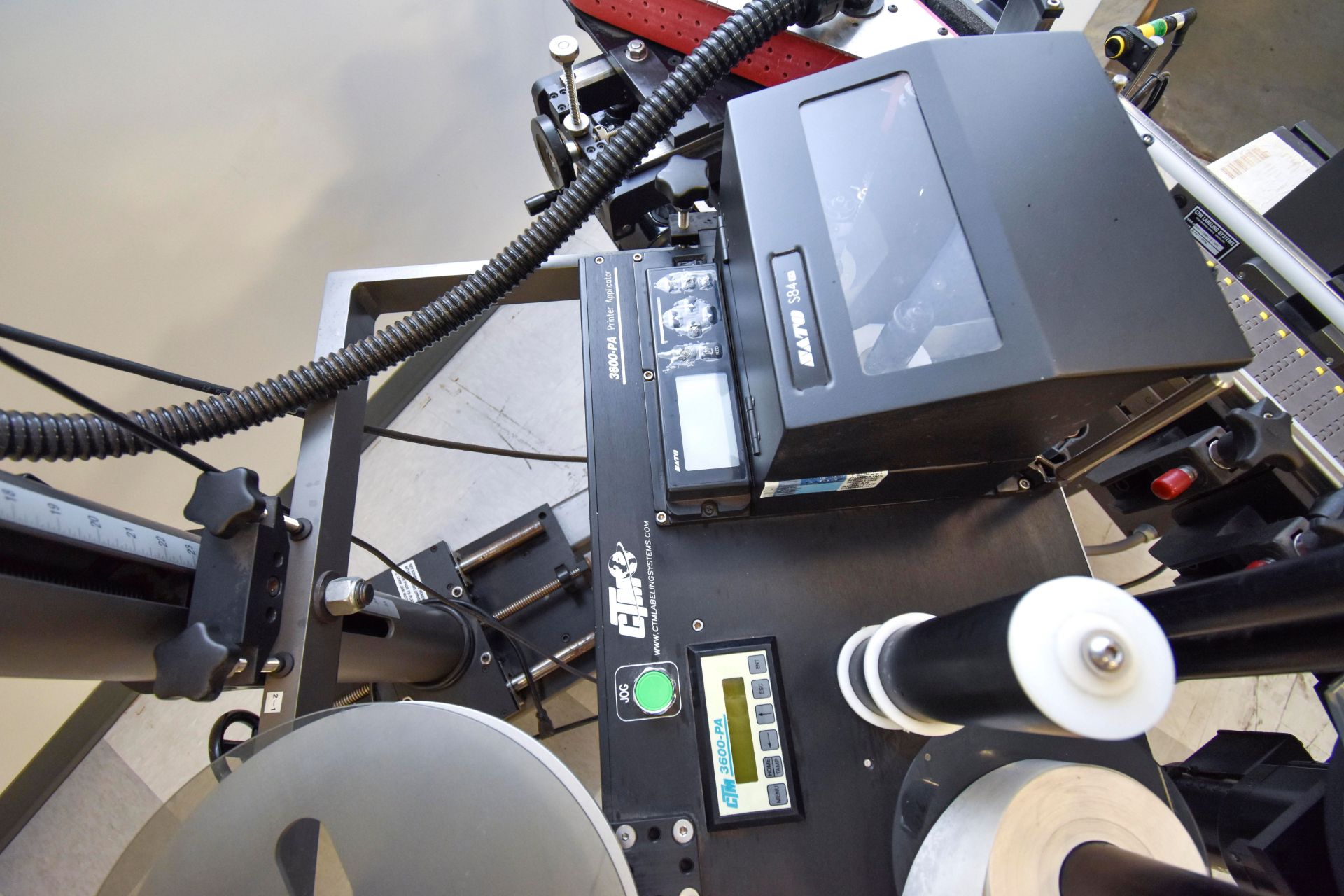

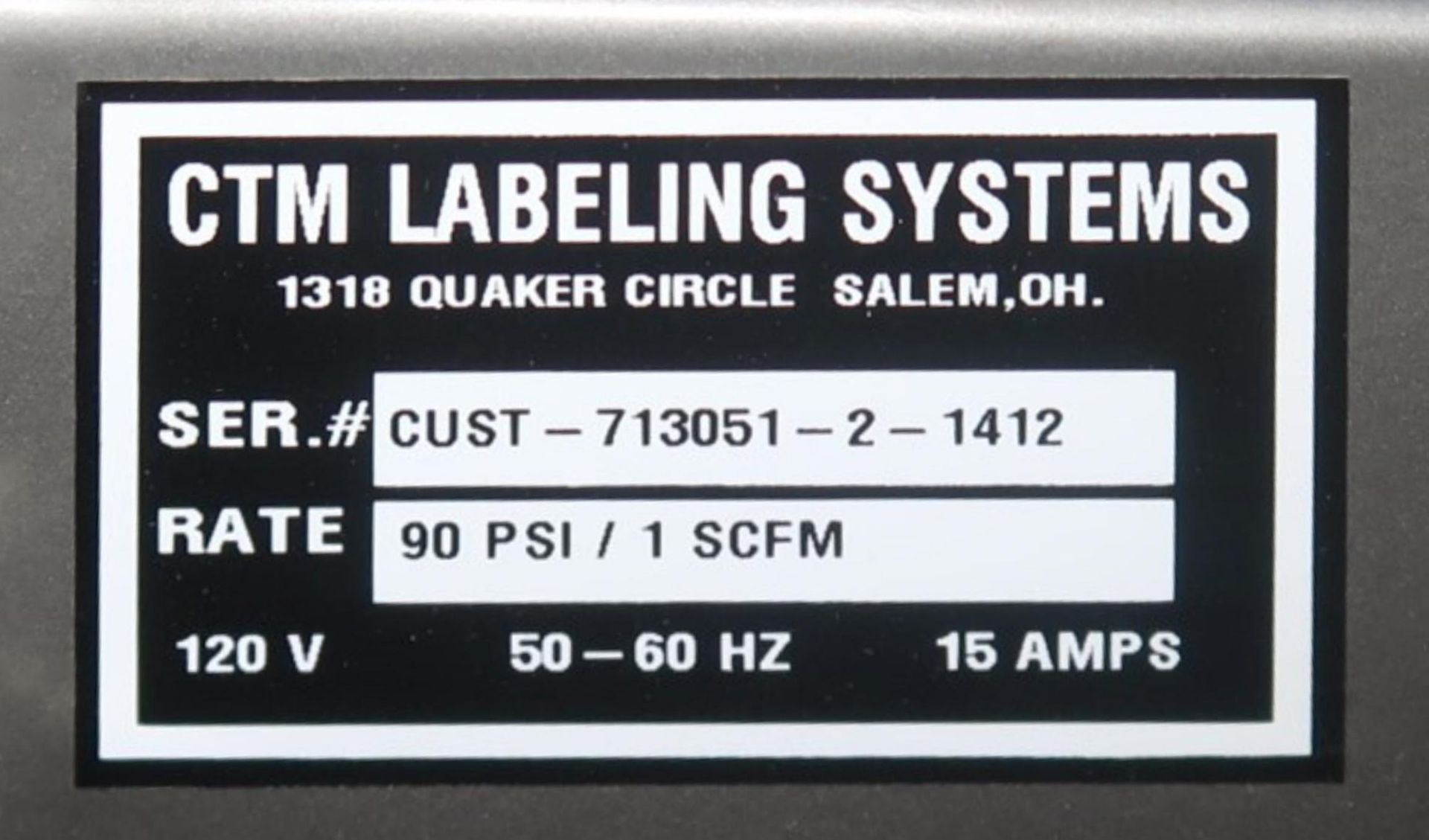

CTM MDL: 3600-PA Printer Applicator Labeling System & Conveyor

Easy to operate, economical, and highly reliable, the Labelette Automatic Pressure Sensitive (APS) labeling machines are your ideal solution for pressure sensitive labeling of plastic, metal, fiber, and glass containers. The APS labelers can handle both cylindrical and oblong containers. The speed, versatility, and reliability of the Labelette APS labelers exceed the competition in labeling equipment technology at a fraction of the price. A variety of models are available to accommodate a wide range of labeling projects.

Standard Machine

Features include Heavy Duty Construction, Tamp Blow Applicator,

External Valves and Controls, Remote Operator Color Touchscreen

Display, 12" O.D. Label Roll, I/O Connection and Communication

Port Connections.

Optional features include Low Label/Low Ribbon, Out of Label/

Out of Ribbon, End of Web, Red, Amber and Green “Ready” Stack

Lights and 16" Unwind and High Capacity Rewind for large label rolls.

Dimensions

31.5" L x 27.5" W x 23.5" H

Weight Approx. 150 lbs.

Electrical:108-132 Volts AC, 5 Amps, 50/60 Hertz, Single Phase

Pneumatic

90 psi., 3-5 cfm

Communications

RS 232, Parallel, Ethernet, USB or Wireless

Environmental Operating: 41OF to 104OF Storage: -4OF to 104OF

(5OC to 40OC) (-20OC to 40OC)

Printing Methods

Thermal Transfer & Direct Thermal

Purchased New in 2015

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location:Azusa,CA

1-Used 360a-WR Wrap System With 1-Used CTM MDL: 3600-PA Printer Applicator Labeling System & Conveyor

360a-WR Wrap System

Features:

For the cost conscious, low volume or entry level partners the

CTM 360a WR wrap labeling system provides the ideal way for

high quality round product labeling. It uses CTM’s advanced 360a

merge applicator with remote HMI operator touch screen color

display. The 360a is available in the 5" wide and 7-1/2" wide

versions accommodating nearly all applications. For multiple labels

the 360a has 48 label format storage for operator selection- no

need to re-calibrate the same labels.

Compact and complete the unit measures a 4' x 4' square footprint

with the 6" wide x 4 ft. long conveyor, wrap belt assembly and ball

bushing traverse for the labeler. Independent speed adjustments

allow set ups for various product and label sizes and cycle rates.

The 360a WR system is provided only as a “build and ship” system

for economy.

Electrical / Pneumatic:

108-132 Volts AC, 50/60 Hertz, Single Phase, 7 Amps.

Environmental:

Operating: 41° F to 104° F (5° C to 40° C)

Storage: -4° F to 105° F (-20° C to 40° C)

Optional Features:

Low label, Low Ribbon, End of Web, End of Ribbon

Stack light (silent or audible)

Consult CTM Labeling Systems for other options

Weight:

Approx. 700 lbs.

CTM MDL: 3600-PA Printer Applicator Labeling System & Conveyor

Easy to operate, economical, and highly reliable, the Labelette Automatic Pressure Sensitive (APS) labeling machines are your ideal solution for pressure sensitive labeling of plastic, metal, fiber, and glass containers. The APS labelers can handle both cylindrical and oblong containers. The speed, versatility, and reliability of the Labelette APS labelers exceed the competition in labeling equipment technology at a fraction of the price. A variety of models are available to accommodate a wide range of labeling projects.

Standard Machine

Features include Heavy Duty Construction, Tamp Blow Applicator,

External Valves and Controls, Remote Operator Color Touchscreen

Display, 12" O.D. Label Roll, I/O Connection and Communication

Port Connections.

Optional features include Low Label/Low Ribbon, Out of Label/

Out of Ribbon, End of Web, Red, Amber and Green “Ready” Stack

Lights and 16" Unwind and High Capacity Rewind for large label rolls.

Dimensions

31.5" L x 27.5" W x 23.5" H

Weight Approx. 150 lbs.

Electrical:108-132 Volts AC, 5 Amps, 50/60 Hertz, Single Phase

Pneumatic

90 psi., 3-5 cfm

Communications

RS 232, Parallel, Ethernet, USB or Wireless

Environmental Operating: 41OF to 104OF Storage: -4OF to 104OF

(5OC to 40OC) (-20OC to 40OC)

Printing Methods

Thermal Transfer & Direct Thermal

Purchased New in 2015

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location:Azusa,CA

PHARMA, VITA, FOOD Manufacturing Equipment Auction, Multiple Locations

Ends from

Venue Address

General delivery information available from the auctioneer

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Important Information

PHARMA, VITA, FOOD Equipment AUCTION

Auction Date: lots start closing on Thursday, January 23rd at 10:00 am PST

Featuring Pharmaceutical Equipment & Machinery as well as Food Equipment, such as: High Capacity Granulation Machine, 20 Station Tablet Presses, Capsule Filling Machines, Tablet Counters, Encapsulators, Metal Inspection,Weight checkers, Coating Pans, Tablet/Capsule Counters, Pharma Pack Cotton Inserters, De-Duster Machines, Automatic Capsule Fillers, Blenders, Mills, Sorters and more.

***PLEASE NOTE***

Assets in this auction are located at various locations.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms and Conditions

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises will be accepted for payment. No equipment will be removed from the sale site until payment is received by Chris Hillseth Enterprises. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- While descriptions are believed to be correct, the seller’s agent or the owners make no warranties or guarantees expressed or implied, as to the genuineness, authenticity of, or defect in any lot and will not be held responsible for advertising discrepancies or inaccuracies. Everything sold AS IS and WHERE IS except as expressly made in writing. No warranties are made as to the merchantability of any items or their fitness for any purpose. Inspect before you bid, absolutely no warranty or guarantee of any kind, either written or implied.

- For bidding approval, at its discretion, Chris Hillseth Enterprises Corp may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If Chris Hillseth Enterprises does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, Chris Hillseth Enterprises reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless Seller its directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Sellers agent and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Randy Aguilar at (818)495-3038 randy@hillseth.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com