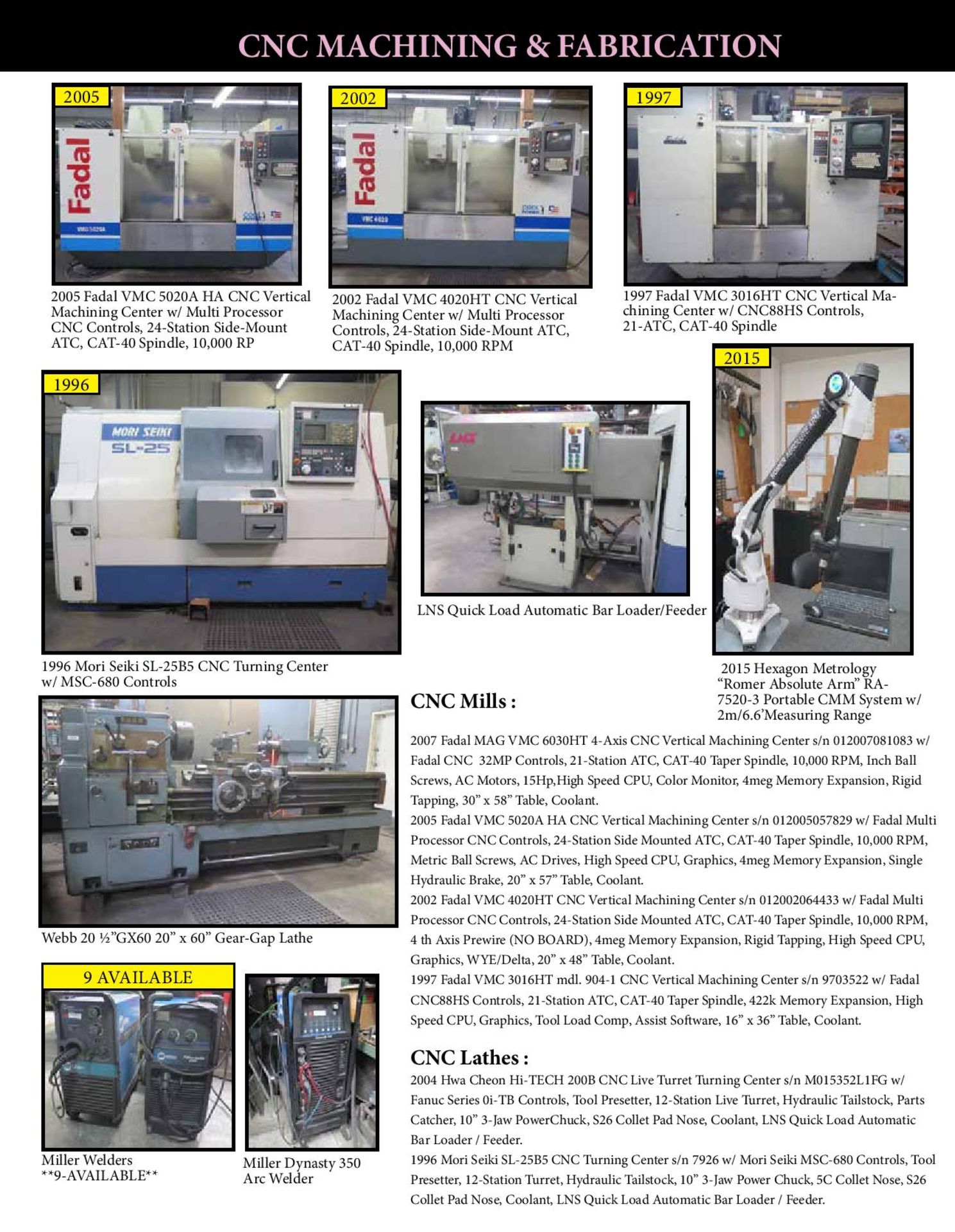

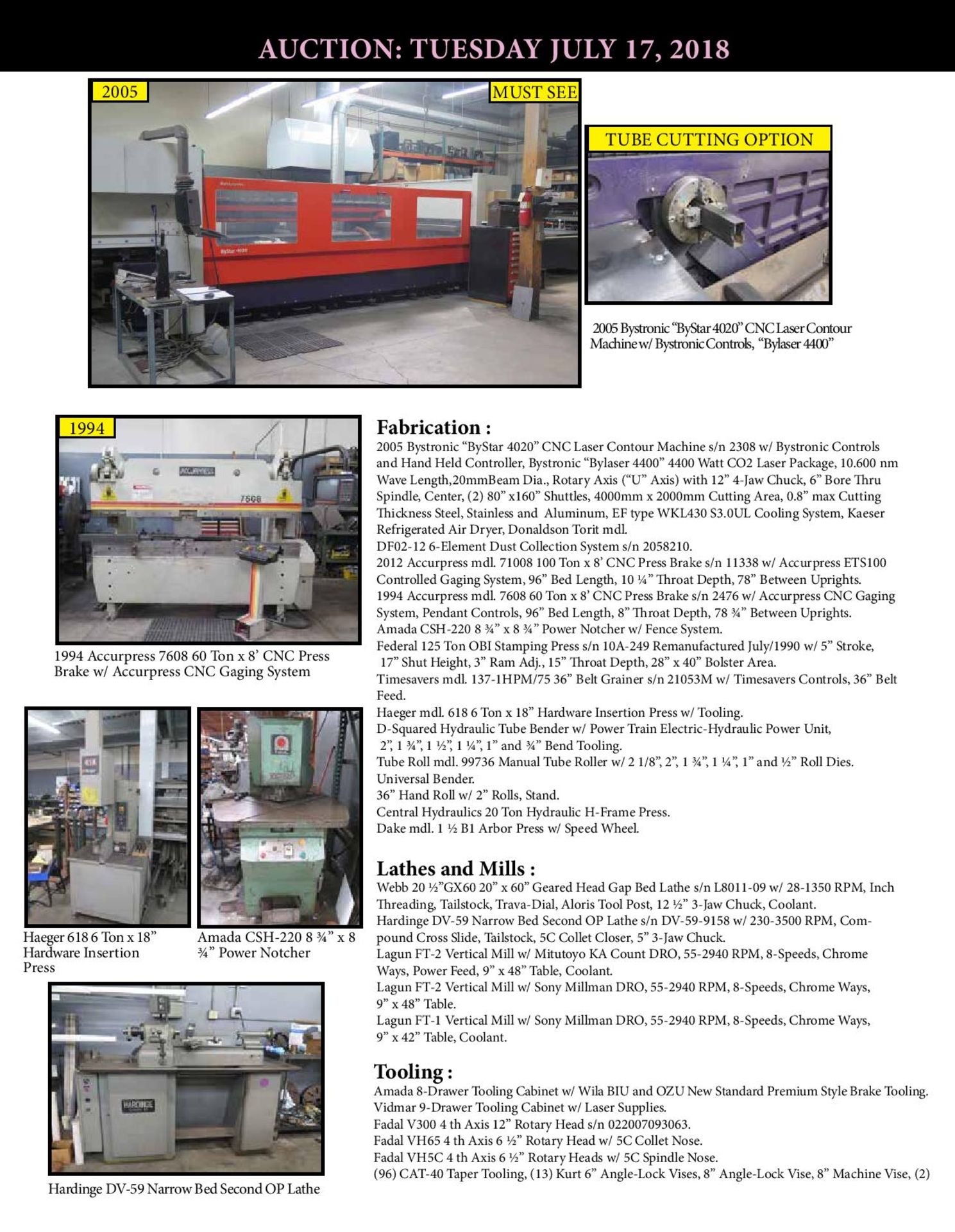

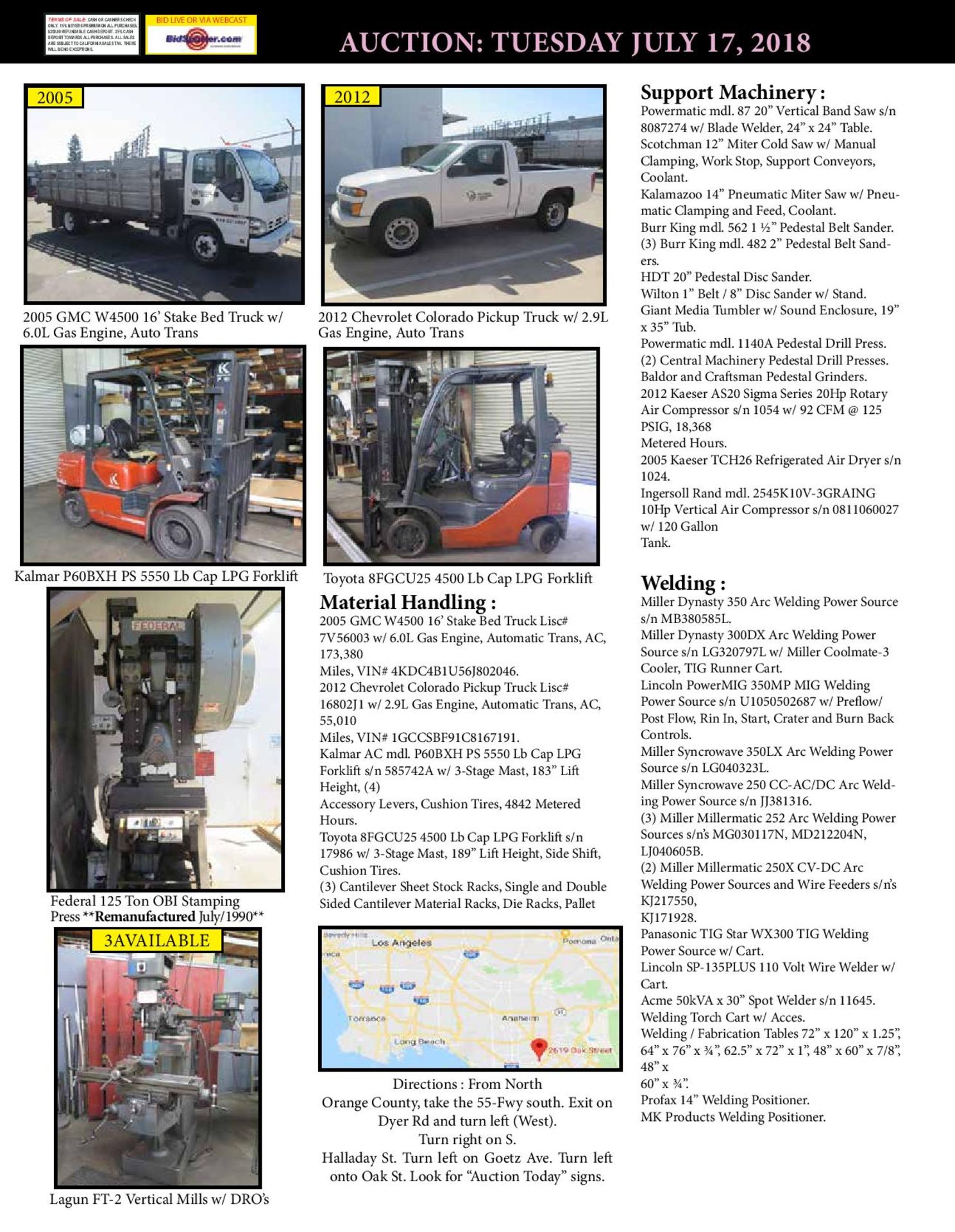

CNC Mills : 2007 Fadal MAG VMC 6030HT 4-Axis CNC Vertical Machining Center s/n 012007081083 w/ Fadal CNC 32MP Controls, 21-Station ATC, CAT-40 Taper Spindle, 10,000 RPM, Inch Ball Screws, AC Motors, 15Hp,High Speed CPU, Color Monitor, 4meg Memory Expansion, Rigid Tapping, 30” x 58” Table, Coolant. 2005 Fadal VMC 5020A HA CNC Vertical Machining Center s/n 012005057829 w/ Fadal Multi Processor CNC Controls, 24-Station Side Mounted ATC, CAT-40 Taper Spindle, 10,000 RPM, Metric Ball Screws, AC Drives, High Speed CPU, Graphics, 4meg Memory Expansion, Single Hydraulic Brake, 20” x 57” Table, Coolant. 2002 Fadal VMC 4020HT CNC Vertical Machining Center s/n 012002064433 w/ Fadal Multi Processor CNC Controls, 24-Station Side Mounted ATC, CAT-40 Taper Spindle, 10,000 RPM, 4 th Axis Prewire (NO BOARD), 4meg Memory Expansion, Rigid Tapping, High Speed CPU, Graphics, WYE/Delta, 20” x 48” Table, Coolant. 1997 Fadal VMC 3016HT mdl. 904-1 CNC Vertical Machining Center s/n 9703522 w/ Fadal CNC88HS Controls, 21-Station ATC, CAT-40 Taper Spindle, 422k Memory Expansion, High Speed CPU, Graphics, Tool Load Comp, Assist Software, 16” x 36” Table, Coolant. CNC Lathes : 2004 Hwa Cheon Hi-TECH 200B CNC Live Turret Turning Center s/n M015352L1FG w/ Fanuc Series 0i-TB Controls, Tool Presetter, 12-Station Live Turret, Hydraulic Tailstock, Parts Catcher, 10” 3-Jaw PowerChuck, S26 Collet Pad Nose, Coolant, LNS Quick Load Automatic Bar Loader / Feeder. 1996 Mori Seiki SL-25B5 CNC Turning Center s/n 7926 w/ Mori Seiki MSC-680 Controls, Tool Presetter, 12-Station Turret, Hydraulic Tailstock, 10” 3-Jaw Power Chuck, 5C Collet Nose, S26 Collet Pad Nose, Coolant, LNS Quick Load Automatic Bar Loader / Feeder.Fabrication : 2005 Bystronic “ByStar 4020” CNC Laser Contour Machine s/n 2308 w/ Bystronic Controls and Hand Held Controller, Bystronic “Bylaser 4400” 4400 Watt CO2 Laser Package, 10.600 nm Wave Length,20mmBeam Dia., Rotary Axis (“U” Axis) with 12” 4-Jaw Chuck, 6” Bore Thru Spindle, Center, (2) 80” x160” Shuttles, 4000mm x 2000mm Cutting Area, 0.8” max Cutting Thickness Steel, Stainless and Aluminum, EF type WKL430 S3.0UL Cooling System, Kaeser Refrigerated Air Dryer, Donaldson Torit mdl. DF02-12 6-Element Dust Collection System s/n 2058210. 2012 Accurpress mdl. 71008 100 Ton x 8’ CNC Press Brake s/n 11338 w/ Accurpress ETS100 Controlled Gaging System, 96” Bed Length, 10 ¼” Throat Depth, 78” Between Uprights. 1994 Accurpress mdl. 7608 60 Ton x 8’ CNC Press Brake s/n 2476 w/ Accurpress CNC Gaging System, Pendant Controls, 96” Bed Length, 8” Throat Depth, 78 ¾” Between Uprights. Amada CSH-220 8 ¾” x 8 ¾” Power Notcher w/ Fence System. Federal 125 Ton OBI Stamping Press s/n 10A-249 Remanufactured July/1990 w/ 5” Stroke, 17” Shut Height, 3” Ram Adj., 15” Throat Depth, 28” x 40” Bolster Area. Timesavers mdl. 137-1HPM/75 36” Belt Grainer s/n 21053M w/ Timesavers Controls, 36” Belt Feed. Haeger mdl. 618 6 Ton x 18” Hardware Insertion Press w/ Tooling. D-Squared Hydraulic Tube Bender w/ Power Train Electric-Hydraulic Power Unit, 2”, 1 ¾”, 1 ½”, 1 ¼”, 1” and ¾” Bend Tooling. Tube Roll mdl. 99736 Manual Tube Roller w/ 2 1/8”, 2”, 1 ¾”, 1 ¼”, 1” and ½” Roll Dies. Universal Bender. 36” Hand Roll w/ 2” Rolls, Stand. Central Hydraulics 20 Ton Hydraulic H-Frame Press. Dake mdl. 1 ½ B1 Arbor Press w/ Speed Wheel. Lathes and Mills : Webb 20 ½”GX60 20” x 60” Geared Head Gap Bed Lathe s/n L8011-09 w/ 28-1350 RPM, Inch Threading, Tailstock, Trava-Dial, Aloris Tool Post, 12 ½” 3-Jaw Chuck, Coolant. Hardinge DV-59 Narrow Bed Second OP Lathe s/n DV-59-9158 w/ 230-3500 RPM, Compound Cross Slide, Tailstock, 5C Collet Closer, 5” 3-Jaw Chuck. Lagun FT-2 Vertical Mill w/ Mitutoyo KA Count DRO, 55-2940 RPM, 8-Speeds, Chrome Ways, Power Feed, 9” x 48” Table, Coolant. Lagun FT-2 Vertical Mill w/ Sony Millman DRO, 55-2940 RPM, 8-Speeds, Chrome Ways, 9” x 48” Table. Lagun FT-1 Vertical Mill w/ Sony Millman DRO, 55-2940 RPM, 8-Speeds, Chrome Ways, 9” x 42” Table, Coolant. Tooling : Amada 8-Drawer Tooling Cabinet w/ Wila BIU and OZU New Standard Premium Style Brake Tooling. Vidmar 9-Drawer Tooling Cabinet w/ Laser Supplies. Fadal V300 4 th Axis 12” Rotary Head s/n 022007093063. Fadal VH65 4 th Axis 6 ½” Rotary Head w/ 5C Collet Nose. Fadal VH5C 4 th Axis 6 ½” Rotary Heads w/ 5C Spindle Nose. (96) CAT-40 Taper Tooling, (13) Kurt 6” Angle-Lock Vises, 8” Angle-Lock Vise, 8” Machine Vise, (2)Support Machinery : Powermatic mdl. 87 20” Vertical Band Saw s/n 8087274 w/ Blade Welder, 24” x 24” Table. Scotchman 12” Miter Cold Saw w/ Manual Clamping, Work Stop, Support Conveyors, Coolant. Kalamazoo 14” Pneumatic Miter Saw w/ Pneumatic Clamping and Feed, Coolant. Burr King mdl. 562 1 ½” Pedestal Belt Sander. (3) Burr King mdl. 482 2” Pedestal Belt Sanders. HDT 20” Pedestal Disc Sander. Wilton 1” Belt / 8” Disc Sander w/ Stand. Giant Media Tumbler w/ Sound Enclosure, 19” x 35” Tub. Powermatic mdl. 1140A Pedestal Drill Press. (2) Central Machinery Pedestal Drill Presses. Baldor and Craftsman Pedestal Grinders. 2012 Kaeser AS20 Sigma Series 20Hp Rotary Air Compressor s/n 1054 w/ 92 CFM @ 125 PSIG, 18,368 Metered Hours. 2005 Kaeser TCH26 Refrigerated Air Dryer s/n 1024. Ingersoll Rand mdl. 2545K10V-3GRAING 10Hp Vertical Air Compressor s/n 0811060027 w/ 120 Gallon Tank. Material Handling : 2005 GMC W4500 16’ Stake Bed Truck Lisc# 7V56003 w/ 6.0L Gas Engine, Automatic Trans, AC, 173,380 Miles, VIN# 4KDC4B1U56J802046. 2012 Chevrolet Colorado Pickup Truck Lisc# 16802J1 w/ 2.9L Gas Engine, Automatic Trans, AC, 55,010 Miles, VIN# 1GCCSBF91C8167191. Kalmar AC mdl. P60BXH PS 5550 Lb Cap LPG Forklift s/n 585742A w/ 3-Stage Mast, 183” Lift Height, (4) Accessory Levers, Cushion Tires, 4842 Metered Hours. Toyota 8FGCU25 4500 Lb Cap LPG Forklift s/n 17986 w/ 3-Stage Mast, 189” Lift Height, Side Shift, Cushion Tires. (3) Cantilever Sheet Stock Racks, Single and Double Sided Cantilever Material Racks, Die Racks, Pallet Welding : Miller Dynasty 350 Arc Welding Power Source s/n MB380585L. Miller Dynasty 300DX Arc Welding Power Source s/n LG320797L w/ Miller Coolmate-3 Cooler, TIG Runner Cart. Lincoln PowerMIG 350MP MIG Welding Power Source s/n U1050502687 w/ Preflow/ Post Flow, Rin In, Start, Crater and Burn Back Controls. Miller Syncrowave 350LX Arc Welding Power Source s/n LG040323L. Miller Syncrowave 250 CC-AC/DC Arc Welding Power Source s/n JJ381316. (3) Miller Millermatic 252 Arc Welding Power Sources s/n’s MG030117N, MD212204N, LJ040605B. (2) Miller Millermatic 250X CV-DC Arc Welding Power Sources and Wire Feeders s/n’s KJ217550, KJ171928. Panasonic TIG Star WX300 TIG Welding Power Source w/ Cart. Lincoln SP-135PLUS 110 Volt Wire Welder w/ Cart. Acme 50kVA x 30” Spot Welder s/n 11645. Welding Torch Cart w/ Acces. Welding / Fabrication Tables 72” x 120” x 1.25”, 64” x 76” x ¾”, 62.5” x 72” x 1”, 48” x 60” x 7/8”, 48” x 60” x ¾”. Profax 14” Welding Positioner. MK Products Welding Positioner.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Thursday, 8:00 AM EST – 10:00 PM EST

- Friday, 8:00 AM EST – 6:30 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Frequently Asked Questions

Terms and Conditions

BY REGISTERING TO BID ON LINE, ALL Registered BIDDERS ARE AGREEING TO ALL THE FOLLOWING TERMS AND CONDITIONS:

1) If registering online, all registered bidders must provide email address and fax number in order to process proper invoice.

2) Bidders by registering assume a legal responsibility to pay for lots sold to him with no exchanges, refunds, adjustments, or refusals.

PURCHASERS ARE TO SATISFY THEMSELVES AS TO CONDITIONS, QUALITY AND DESCRIPTION OF LOTS BEFORE BIDDING.

3) All lots are offered AS IS, WHERE IS, and become the property and responsibility of the bidder at time of the sale.

All lots to be sold as shown, with all faults, imperfections and errors of description. All SALES ARE FINAL.

4) No warranties or guarantees, expressed or implied are made by the auctioneer, concerning the accurace of description, genuineness, authenticity, or condition of lots.

5) A 18% BUYERS PREMIUM WILL BE PAID BY THE BUYER AS PART OF THE PURCHASE PRICE.

6) American Auctioneers Group, Inc. are not responsible for accidents, damage or loss of any kind to bidders, persons online or their property. We cannot be responsible and assume no liability for the packing, loading or securing of merchandise to your vehicle or truck.

All winning bidders are responsible to hire an insured rigger for the removal of items.

7) All purchases must be removed from the premises in the time allocated, as announced by the auctioneer.

8) A deposit of 25% of purchases will be required of every buyer. The deposit and final payment must be paid for by CASH, CASHIER'S CHECK OR WIRE TRANSFER BEFORE REMOVAL.

Deposits will not be returned if, items are not removed or paid for within the time announced or posted.

9) All buyers shall, at the time of purchase pay any state and local taxes, unless documentation is on file with AAG exempting from such taxes.

10) While quantities and description are believed to be correct, there are no guarantees and the auctioneers, owners, and advertising counsel will not be held responsible for advertising discrepancies, inaccuracies or failure of merchandise to correspond with any standard expected. All lots shall auctioned and bid upon lot number.

11) The auctioneer shall in no event be liable to the purchaser for non delivery of any lot for any reason except for the return to the purchaser of the deposit or money paid on such non delivered lots.

.

ANY ITEMS NOT REMOVED ON OR BEFORE THE REMOVAL DATE SHALL BE DEEMED ABANDONED AND WILL BE REMOVED AND SCRAPPED AT THE BUYERS EXPENSE

12) ALL SALES IN U.S. DOLLARS ONLY

13) If you do not have a credit card to register with bidspotter, then please call our office at 818-763-2021 and make arrangements to overnight checks.

14) PAYMENTS MUST BE MADE OR WIRE INITIATED BY CLOSE OF BUSINESS THE DAY AFTER THE SALE. Credit card authorization and company checks (not accompanied by bank letter) are for deposit only, and in the case of company checks (not accompanied by bank letters), will be returned to customer once full payment in cash, cashier's check or wire transfer is made.

INTERNET BUYERS PREMIUM IS 18%.

ALL SALES TAX WILL BE SUBJECT TO LOCAL SALES TAX.

AAG OFFICE NUMBER IS 818-763-2021

AAG FAX NUMBER IS 818-291-9495

Cash, Cashier check, or Wire transfer ONLY.

Credit Card is required for registrations but cannot be used for purchases.

See Full Terms And Conditions