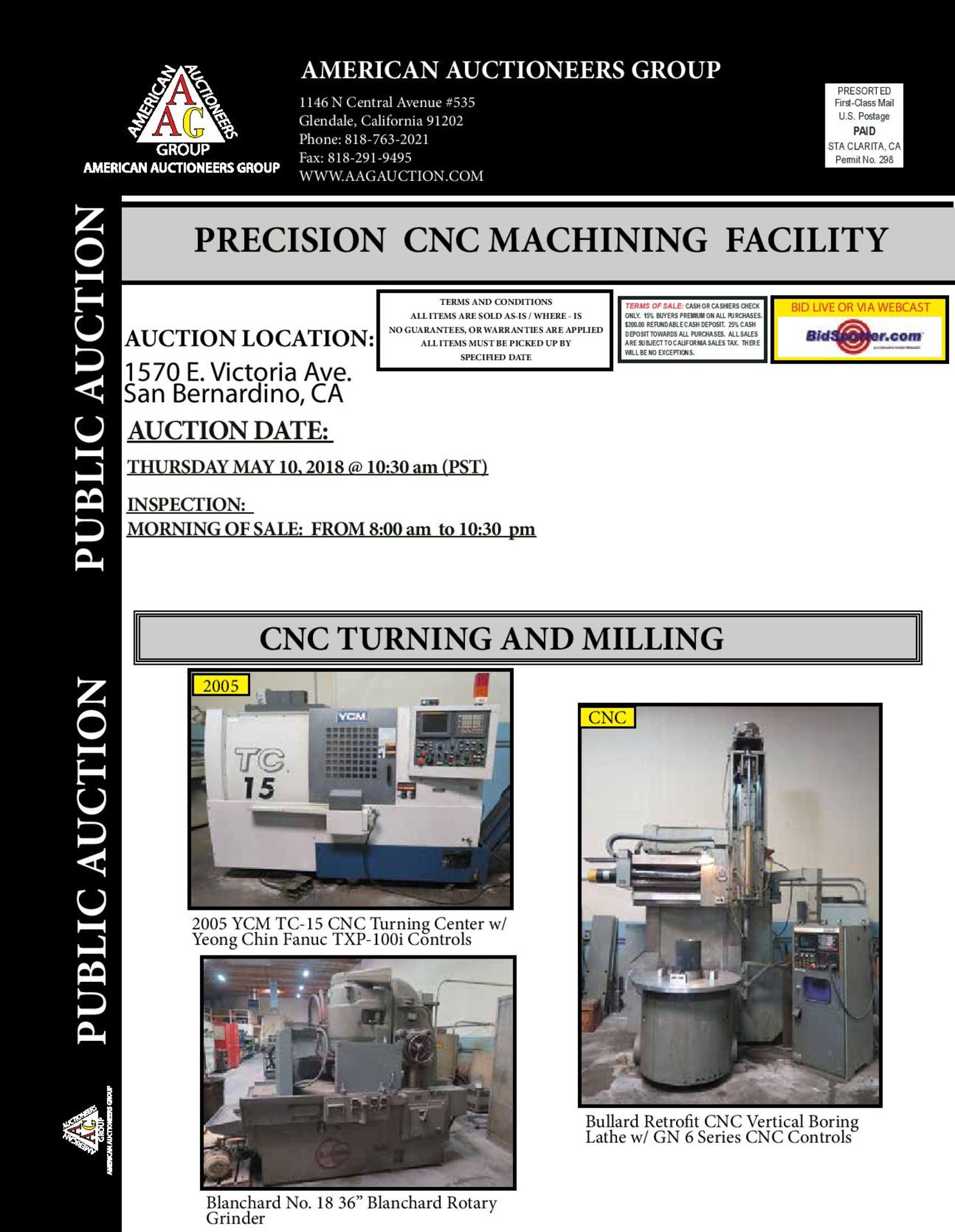

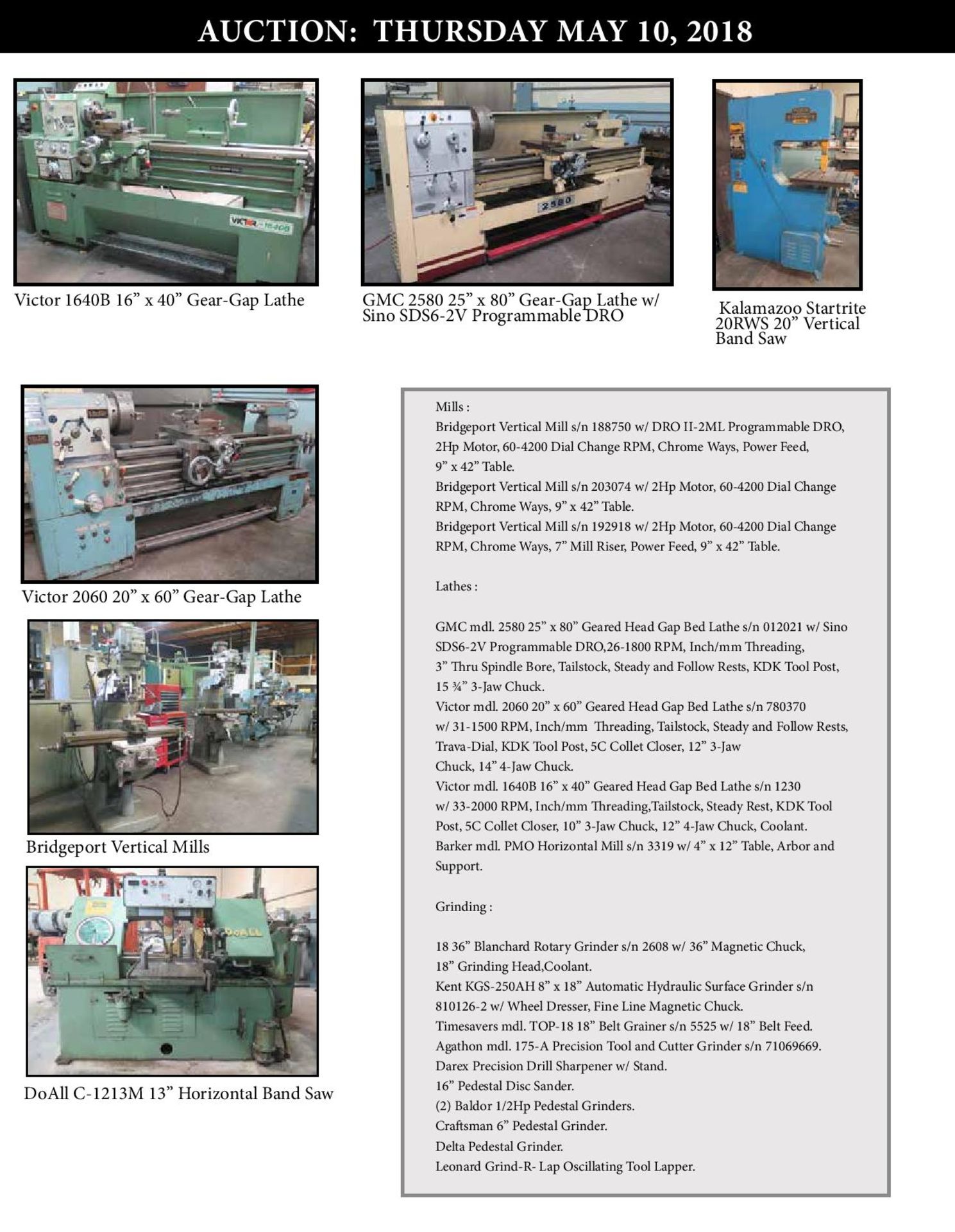

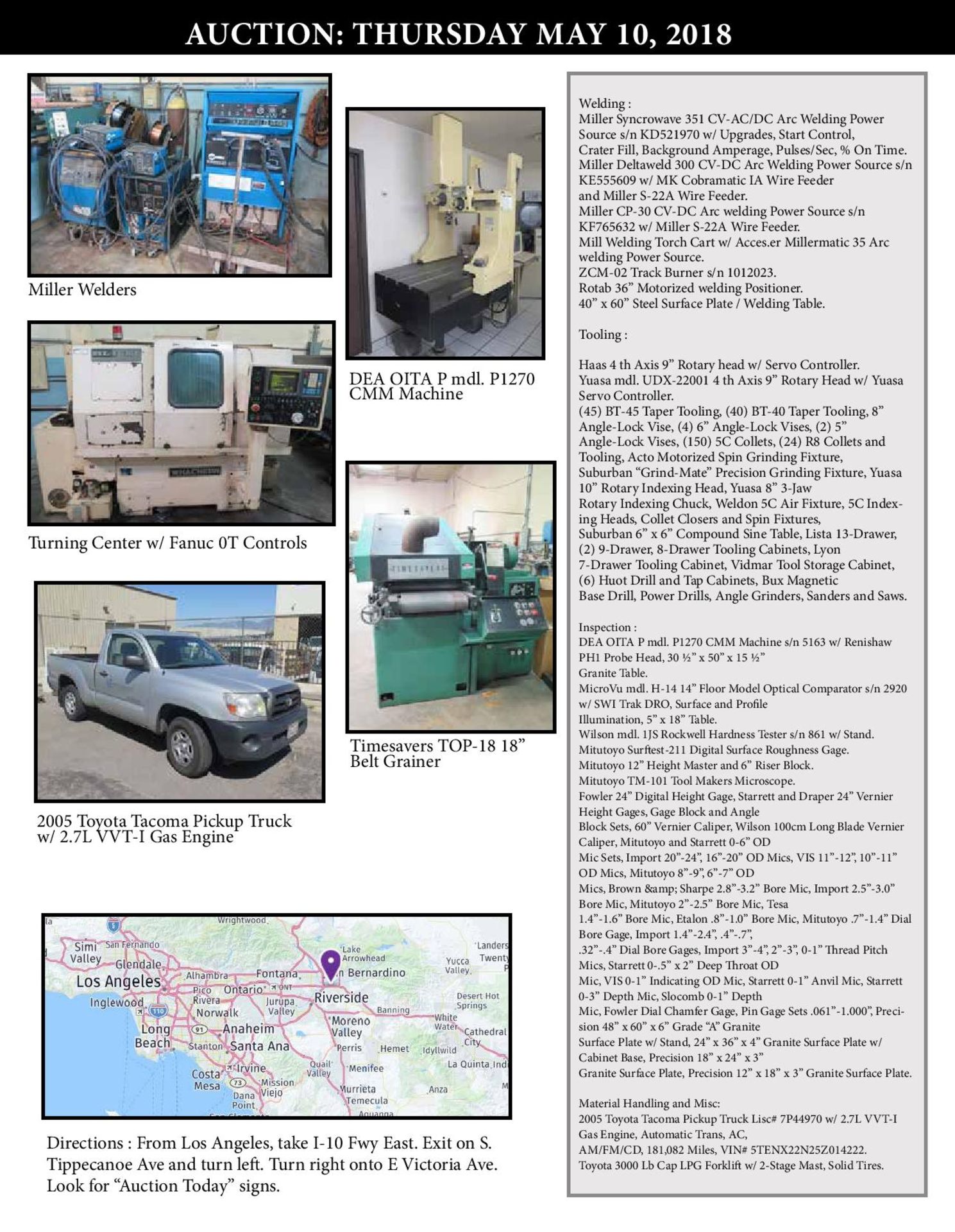

CNC Mills : Matsuura MC-1000V 4-Axis CNC Vertical Machining Center s/n 84064084 w/ Fanuc System 6M Controls, 35-Station ATC, BT-45 Taper Spindle, 200-3580 RPM, Travels “X”=41.3”, “Y”=20”, “Z”=22”, 4 th -Axis 12” Rotary Head, Coolant. Mori Seiki MV-45/40 CNC Vertical Machining Center s/n 628 w/ Fanuc System 11M Controls, 20-Station ATC, BT-40 Taper Spindle, Memory Upgrade, 18” x 44” Table, Chip Conveyor, Coolant. Mori Seiki MV-40 CNC Vertical Machining Center s/n 69 w/ Fanuc System 6M Controls, 20-Station ATC, BT-40 Taper Spindle, 60-6000 RPM, Travels “X”=30”, “Y”=13.78”, “Z”= 19.68”, 14” x 42” Table, Coolant. Victor V Center-4 CNC Vertical Machining Center w/ Fanuc 10M Controls, 16-Station ATC, BT-40 Taper Spindle, 150-6000 RPM, Travels “X”=22”, “Y”=16”, “Z”=18”, 16 ½” x 36” Table, Coolant. Fadal VMC4020 mdl. 904-1 CNC Vertical Machining Center s/n 8604408 w/ Fadal CNC88 Controls, 21- Station ATC, CAT-40 Taper Spindle, 10,000 RPM, 20” x 48” Table, Coolant.CNC Lathes : 2005 YCM TC-15 CNC Turning Center s/n 0755 w/ Yeong Chin Fanuc TXP-100i Controls, 12-Station Turret, Hydraulic Tailstock, 8” 3-Jaw Power Chuck, Chip Conveyor Coolant. Bullard Retrofit CNC Vertical Boring Lathe w/ GN 6 Series CNC Controls, 36” Chuck. Mazak M4 22” x 68” CNC Twin Turret CNC Gap Bed Lathe w/ Fanuc 5T Controls, 6-Station Drill/Bore Turret, 8-Station Turning Turret, Hydraulic Tailstock, Steady Rest, 12” 3-Jaw Chuck, Coolant. Takisawa TC-2 CNC Turning Center s/n C8905038- 241 w/ Fanuc 0T Controls, 8-Station Turret, Hydraulic Tailstock, 8” 3-Jaw Power Chuck, Coolant. Whacheon RL-1CNC CNC Turning Center s/n 8809- 100 w/ Fanuc 0T Controls, 6-Station Turret, 8” x 13” Cross Slide Tooling Table, 5C Collet Nose, Coolant, Bar Feed. Wickman 26-130 CNC Cross Slide Lathe s/n 28024 w/ GE Fanuc 0T Controls, Crawford Colleted Spindle, Part Chute, 7 ¾” x 30 ¼” Table, Ikura Seiki “Bartop” Automatic Bar Loader / Feeder.Support Machinery : Pioneer Broach mdl. VM-215- 3 Vertical Broaching Machine s/n A1019 w/ 11 ½” x 11 ½” Table, Coolant. DoAll mdl. C-1213M 13” Horizontal Band Saw s/n 143-83163 w/ Hydraulic Clamping, Work Stop,Coolant, Conveyor. Kalamazoo Startrite mdl. 20RWS 20” Vertical Band Saw s/n 71793 w/ Blade Welder, Dial Change FPM. MN Thackaberry 14” Abrasive Cutoff Saw. Hansvedt SM-150B Die Sinker EDM Machine w/ mdl. 150B Power Supply, 9” x 15” Tooling Table, Maple-Top Work Bench and Acces. IMC American Compressors mdl. 10BB 10Hp Rotary Vane Air Compressor s/n 99B80064 w/ Ingersoll Rand “Hydrogard” Refrigerated Air Dryer, Vertical Air Storage Tank. Bracker AG mdl. RN002 Radial Riveter s/n 60522. (2) Pedestal Drill Presses. Servo Products mdl. 7000 Precision Micro Drill Press s/n 7465 w/ Work Light, 6” x 6 ½” Table. Milwaukee 14” Abrasive Cutoff Saw. Mills : Bridgeport Vertical Mill s/n 188750 w/ DRO II-2ML Programmable DRO, 2Hp Motor, 60-4200 Dial Change RPM, Chrome Ways, Power Feed, 9” x 42” Table. Bridgeport Vertical Mill s/n 203074 w/ 2Hp Motor, 60-4200 Dial Change RPM, Chrome Ways, 9” x 42” Table. Bridgeport Vertical Mill s/n 192918 w/ 2Hp Motor, 60-4200 Dial Change RPM, Chrome Ways, 7” Mill Riser, Power Feed, 9” x 42” Table.Lathes : GMC mdl. 2580 25” x 80” Geared Head Gap Bed Lathe s/n 012021 w/ Sino SDS6-2V Programmable DRO,26-1800 RPM, Inch/mm Threading, 3” Thru Spindle Bore, Tailstock, Steady and Follow Rests, KDK Tool Post, 15 ¾” 3-Jaw Chuck. Victor mdl. 2060 20” x 60” Geared Head Gap Bed Lathe s/n 780370 w/ 31-1500 RPM, Inch/mm Threading, Tailstock, Steady and Follow Rests, Trava-Dial, KDK Tool Post, 5C Collet Closer, 12” 3-Jaw Chuck, 14” 4-Jaw Chuck. Victor mdl. 1640B 16” x 40” Geared Head Gap Bed Lathe s/n 1230 w/ 33-2000 RPM, Inch/mm Threading,Tailstock, Steady Rest, KDK Tool Post, 5C Collet Closer, 10” 3-Jaw Chuck, 12” 4-Jaw Chuck, Coolant. Barker mdl. PMO Horizontal Mill s/n 3319 w/ 4” x 12” Table, Arbor and Support.Grinding : 18 36” Blanchard Rotary Grinder s/n 2608 w/ 36” Magnetic Chuck, 18” Grinding Head,Coolant. Kent KGS-250AH 8” x 18” Automatic Hydraulic Surface Grinder s/n 810126-2 w/ Wheel Dresser, Fine Line Magnetic Chuck. Timesavers mdl. TOP-18 18” Belt Grainer s/n 5525 w/ 18” Belt Feed. Agathon mdl. 175-A Precision Tool and Cutter Grinder s/n 71069669. Darex Precision Drill Sharpener w/ Stand. 16” Pedestal Disc Sander. (2) Baldor 1/2Hp Pedestal Grinders. Craftsman 6” Pedestal Grinder. Delta Pedestal Grinder. Leonard Grind-R- Lap Oscillating Tool Lapper.Welding : Miller Syncrowave 351 CV-AC/DC Arc Welding Power Source s/n KD521970 w/ Upgrades, Start Control, Crater Fill, Background Amperage, Pulses/Sec, % On Time. Miller Deltaweld 300 CV-DC Arc Welding Power Source s/n KE555609 w/ MK Cobramatic IA Wire Feeder and Miller S-22A Wire Feeder. Miller CP-30 CV-DC Arc welding Power Source s/n KF765632 w/ Miller S-22A Wire Feeder. Mill Welding Torch Cart w/ Acces.er Millermatic 35 Arc welding Power Source. ZCM-02 Track Burner s/n 1012023. Rotab 36” Motorized welding Positioner. 40” x 60” Steel Surface Plate / Welding Table. Tooling : Haas 4 th Axis 9” Rotary head w/ Servo Controller. Yuasa mdl. UDX-22001 4 th Axis 9” Rotary Head w/ Yuasa Servo Controller. (45) BT-45 Taper Tooling, (40) BT-40 Taper Tooling, 8” Angle-Lock Vise, (4) 6” Angle-Lock Vises, (2) 5” Angle-Lock Vises, (150) 5C Collets, (24) R8 Collets and Tooling, Acto Motorized Spin Grinding Fixture, Suburban “Grind-Mate” Precision Grinding Fixture, Yuasa 10” Rotary Indexing Head, Yuasa 8” 3-Jaw Rotary Indexing Chuck, Weldon 5C Air Fixture, 5C Indexing Heads, Collet Closers and Spin Fixtures, Suburban 6” x 6” Compound Sine Table, Lista 13-Drawer, (2) 9-Drawer, 8-Drawer Tooling Cabinets, Lyon 7-Drawer Tooling Cabinet, Vidmar Tool Storage Cabinet, (6) Huot Drill and Tap Cabinets, Bux Magnetic Base Drill, Power Drills, Angle Grinders, Sanders and Saws. Inspection : DEA OITA P mdl. P1270 CMM Machine s/n 5163 w/ Renishaw PH1 Probe Head, 30 ½” x 50” x 15 ½” Granite Table. MicroVu mdl. H-14 14” Floor Model Optical Comparator s/n 2920 w/ SWI Trak DRO, Surface and Profile Illumination, 5” x 18” Table. Wilson mdl. 1JS Rockwell Hardness Tester s/n 861 w/ Stand. Mitutoyo Surftest-211 Digital Surface Roughness Gage. Mitutoyo 12” Height Master and 6” Riser Block. Mitutoyo TM-101 Tool Makers Microscope. Fowler 24” Digital Height Gage, Starrett and Draper 24” Vernier Height Gages, Gage Block and Angle Block Sets, 60” Vernier Caliper, Wilson 100cm Long Blade Vernier Caliper, Mitutoyo and Starrett 0-6” OD Mic Sets, Import 20”-24”, 16”-20” OD Mics, VIS 11”-12”, 10”-11” OD Mics, Mitutoyo 8”-9”, 6”-7” OD Mics, Brown & Sharpe 2.8”-3.2” Bore Mic, Import 2.5”-3.0” Bore Mic, Mitutoyo 2”-2.5” Bore Mic, Tesa 1.4”-1.6” Bore Mic, Etalon .8”-1.0” Bore Mic, Mitutoyo .7”-1.4” Dial Bore Gage, Import 1.4”-2.4”, .4”-.7”, .32”-.4” Dial Bore Gages, Import 3”-4”, 2”-3”, 0-1” Thread Pitch Mics, Starrett 0-.5” x 2” Deep Throat OD Mic, VIS 0-1” Indicating OD Mic, Starrett 0-1” Anvil Mic, Starrett 0-3” Depth Mic, Slocomb 0-1” Depth Mic, Fowler Dial Chamfer Gage, Pin Gage Sets .061”-1.000”, Precision 48” x 60” x 6” Grade “A” Granite & MORE!

BidSpotter Customer Service Support Department

To reach a member of our qualified support staff regarding information or questions pertaining to the bidding process; please reach us by phone or email.

Terms and Conditions

BY REGISTERING TO BID ON LINE, ALL Registered BIDDERS ARE AGREEING TO ALL THE FOLLOWING TERMS AND CONDITIONS:

1) If registering online, all registered bidders must provide email address and fax number in order to process proper invoice.

2) Bidders by registering assume a legal responsibility to pay for lots sold to him with no exchanges, refunds, adjustments, or refusals.

PURCHASERS ARE TO SATISFY THEMSELVES AS TO CONDITIONS, QUALITY AND DESCRIPTION OF LOTS BEFORE BIDDING.

3) All lots are offered AS IS, WHERE IS, and become the property and responsibility of the bidder at time of the sale.

All lots to be sold as shown, with all faults, imperfections and errors of description. All SALES ARE FINAL.

4) No warranties or guarantees, expressed or implied are made by the auctioneer, concerning the accurace of description, genuineness, authenticity, or condition of lots.

5) A 18% BUYERS PREMIUM WILL BE PAID BY THE BUYER AS PART OF THE PURCHASE PRICE.

6) American Auctioneers Group, Inc. are not responsible for accidents, damage or loss of any kind to bidders, persons online or their property. We cannot be responsible and assume no liability for the packing, loading or securing of merchandise to your vehicle or truck.

All winning bidders are responsible to hire an insured rigger for the removal of items.

7) All purchases must be removed from the premises in the time allocated, as announced by the auctioneer.

8) A deposit of 25% of purchases will be required of every buyer. The deposit and final payment must be paid for by CASH, CASHIER'S CHECK OR WIRE TRANSFER BEFORE REMOVAL.

Deposits will not be returned if, items are not removed or paid for within the time announced or posted.

9) All buyers shall, at the time of purchase pay any state and local taxes, unless documentation is on file with AAG exempting from such taxes.

10) While quantities and description are believed to be correct, there are no guarantees and the auctioneers, owners, and advertising counsel will not be held responsible for advertising discrepancies, inaccuracies or failure of merchandise to correspond with any standard expected. All lots shall auctioned and bid upon lot number.

11) The auctioneer shall in no event be liable to the purchaser for non delivery of any lot for any reason except for the return to the purchaser of the deposit or money paid on such non delivered lots.

.

ANY ITEMS NOT REMOVED ON OR BEFORE THE REMOVAL DATE SHALL BE DEEMED ABANDONED AND WILL BE REMOVED AND SCRAPPED AT THE BUYERS EXPENSE

12) ALL SALES IN U.S. DOLLARS ONLY

13) If you do not have a credit card to register with bidspotter, then please call our office at 818-763-2021 and make arrangements to overnight checks.

14) PAYMENTS MUST BE MADE OR WIRE INITIATED BY CLOSE OF BUSINESS THE DAY AFTER THE SALE. Credit card authorization and company checks (not accompanied by bank letter) are for deposit only, and in the case of company checks (not accompanied by bank letters), will be returned to customer once full payment in cash, cashier's check or wire transfer is made.

INTERNET BUYERS PREMIUM IS 18%.

ALL SALES TAX WILL BE SUBJECT TO LOCAL SALES TAX.

AAG OFFICE NUMBER IS 818-763-2021

AAG FAX NUMBER IS 818-291-9495

Cash, Cashier check, or Wire transfer ONLY.

Credit Card is required for registrations but cannot be used for purchases.

See Full Terms And Conditions