1

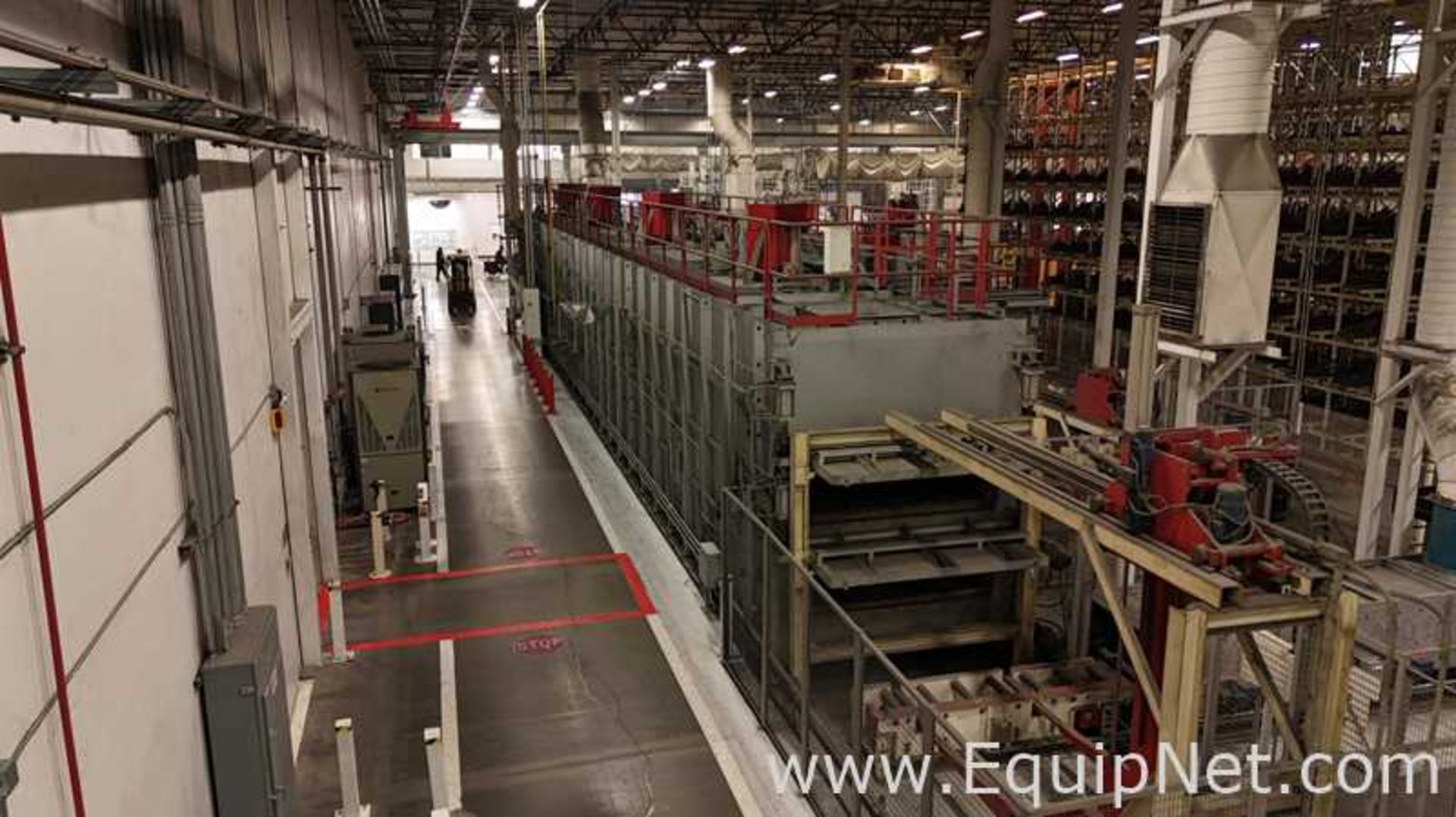

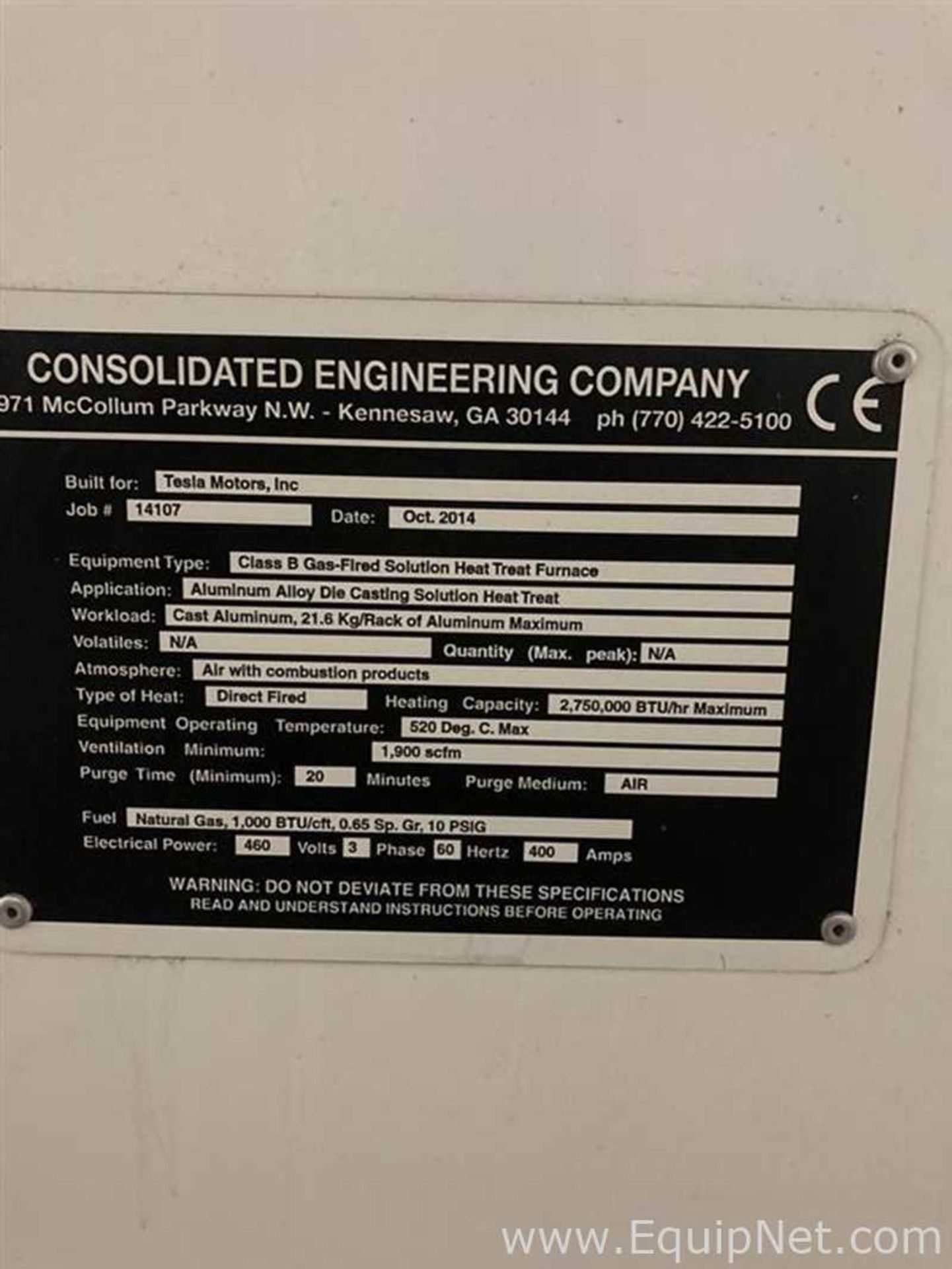

Consolidated Engineering Company Class B Gas Fired Solution Heat Treat Furnace

DESCRIPTION: Consolidated Engineering Company Class B gas Fired Solution Heat Treat Furnace

Four Zone Conveyor Furnace

This machine Will Have The Following Features:

REMOVAL COST: $0

MORE INFORMATION: https://www.equipnet.com/auctions/consolidated-engineering-company-class-b-gas-listid-985059/

DESCRIPTION: Consolidated Engineering Company Class B gas Fired Solution Heat Treat Furnace

Four Zone Conveyor Furnace

This machine Will Have The Following Features:

REMOVAL COST: $0

MORE INFORMATION: https://www.equipnet.com/auctions/consolidated-engineering-company-class-b-gas-listid-985059/

Multi-Location Event! Machine Tools, Fabrication Machinery, Plant Utilities, Converting Equipment, Packaging Equipment, MRO and More!

Se termine à partir de

General delivery information available from the auctioneer

- Removal & Loading (Handling fees) are noted where provided by the vendors - these charges will appear on the buyers final invoice. Please see item description for more details/cost. Additional Services like skidding/crating and shipping can be quoted to winning bidders after their initial equipment invoice has been paid as a service option.

Importantes Informations

Multi-Location Event! Machine Tools, Fabrication Machinery, Plant Utilities, Converting Equipment, Packaging Equipment, MRO and More! : Paper Converting Equipment, Blow Molders, CNC Grinders, Milling Machines, Bridge Cranes, Boilers, 3D Printers, Hoists, Ultrasonic Welders and More!

=====================================================

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Friday, 8:00 AM ET – 8:00 PM ET

Email: support@bidspotter.com

Office: 253-858-6777 Toll Free: 866-597-2437

Conditions Générales de Ventes

EquipNet, Inc. Auction Terms

- **Tax % due to change depending on location of equipment and buyer location.

- All auction equipment is subject to internal redeployment, cancellation of listing, or other sale prior to formal acceptance of an auction bid by the seller.

-

- All bids are binding. Once bids are submitted you cannot remove or modify them, although you can place additional bids. If you make a mistake in your bid, please call our hotline and a Sales Representative will assist you.

- All items, unless otherwise stated, are sold “As Is, Where Is, With All Faults”.

- The sale of equipment is intended to be sold without software or other proprietary intellectual property including but not limited to manuals (“Software”), if any is applicable.

- Handling Fees: are noted where provided by the vendors. Please see item description for more details. This is the cost to get the item from its location to an area where it can safely be loaded (unless otherwise noted). Packaging and Shipping are additional and can be provided once your equipment invoice has been paid.

- Buyer's Premium is 19% - The premium is a percentage of the final price of a listing (item) that is in addition to the equipment sale price. For example, if an auction charges a buyer’s premium of 19% for amounts below $1,000, you will be required to pay an additional $190 for a lot totaling $1,190.

- Taxes / VAT: Sales tax may be applied to your purchase, depending on your state and exemption status. If no sales tax is applied to your order, check your state's sales and use tax requirements as you may be required to self-assess any tax required.

- Your invoices are sent via email initially and can also be viewed from the My EquipNet section of the website. Our payment instructions can be found at the bottom of your invoice. Acceptable payment Methods include credit card with a max of $10,000 USD (Visa, MasterCard, Discover, AmEx), otherwise Wire Transfer ONLY. EquipNet DOES NOT accept checks, PayPal or PO's as payment. All invoices must be paid within (5) days of receipt of invoice.

- Invoices must be paid in full before shipping/pick-up arrangements can be made. Once paid in full, a member of the EquipNet Logistics department will contact you regarding your freight quote.

- All items must be removed within the specified removal period or shall be deemed abandoned and resold by EquipNet, Inc. All quotes must be obtained after the auction has concluded and the item(s) have been paid for. Abandoning items can result in being banned from future bidding.