0

FULL CATALOG COMING SOON. REGISTER TODAY!

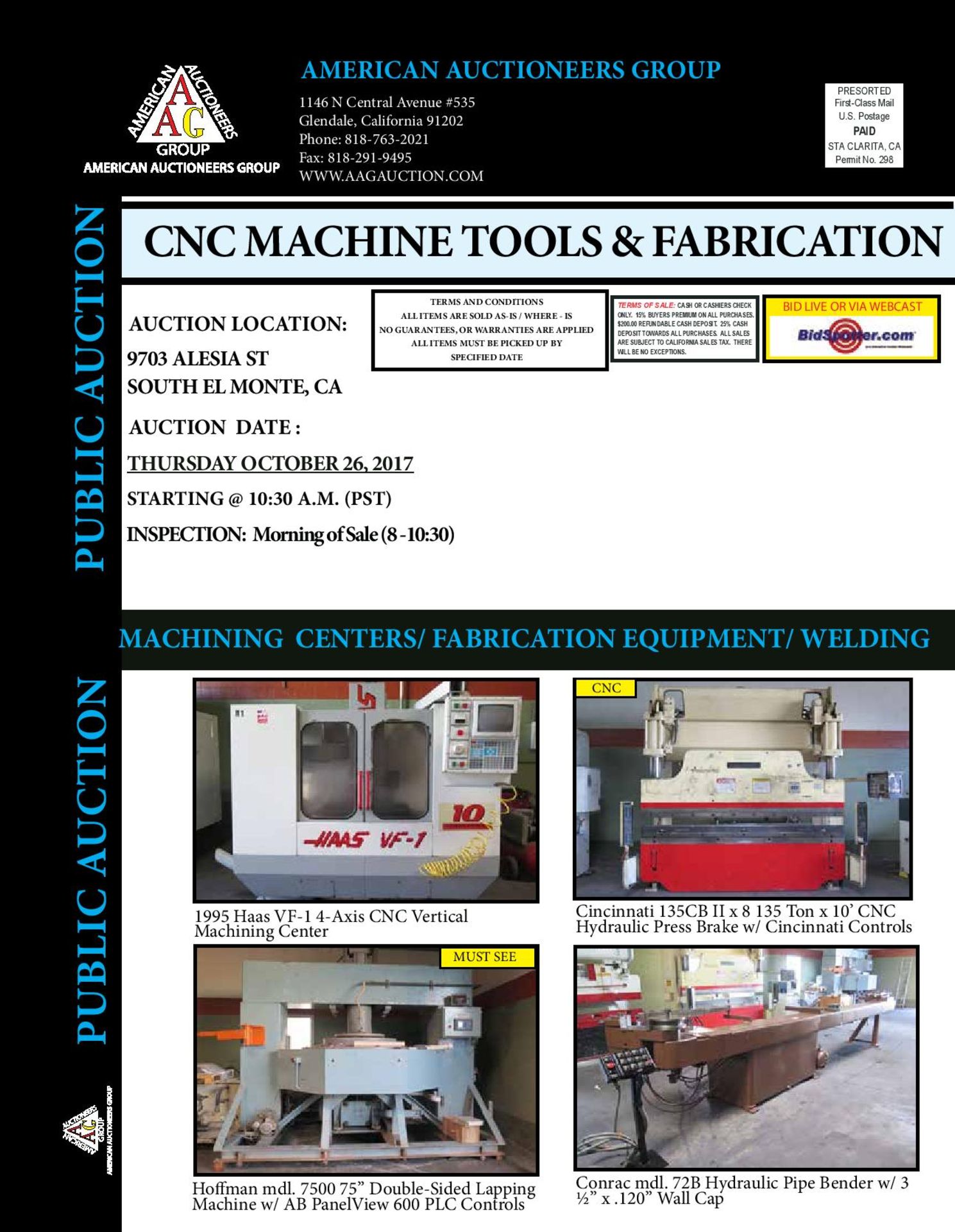

CNC MACHINE TOOLS & FABRICATION

Sale Date(s)

Lieu de la vente

For American Auctioneers Group delivery information please telephone (818) 763-2021.

Importantes Informations

BidSpotter Customer Service Support Department

To reach a member of our qualified support staff regarding information or questions pertaining to the bidding process; please reach us by phone or email.

- Available Monday – Friday, 8:00am – 12:00am ET.

- Email: Support@bidspotter.com

- Office: 253-858-6777

- Frequently Asked Questions

Conditions Générales de Ventes

Terms and Conditions

BY REGISTERING TO BID ON LINE, ALL Registered BIDDERS ARE AGREEING TO ALL THE FOLLOWING TERMS AND CONDITIONS:

1) If registering online, all registered bidders must provide email address and fax number in order to process proper invoice.

2) Bidders by registering assume a legal responsibility to pay for lots sold to him with no exchanges, refunds, adjustments, or refusals.

PURCHASERS ARE TO SATISFY THEMSELVES AS TO CONDITIONS, QUALITY AND DESCRIPTION OF LOTS BEFORE BIDDING.

3) All lots are offered AS IS, WHERE IS, and become the property and responsibility of the bidder at time of the sale.

All lots to be sold as shown, with all faults, imperfections and errors of description. All SALES ARE FINAL.

4) No warranties or guarantees, expressed or implied are made by the auctioneer, concerning the accurace of description, genuineness, authenticity, or condition of lots.

5) A 18% BUYERS PREMIUM WILL BE PAID BY THE BUYER AS PART OF THE PURCHASE PRICE.

6) American Auctioneers Group, Inc. are not responsible for accidents, damage or loss of any kind to bidders, persons online or their property. We cannot be responsible and assume no liability for the packing, loading or securing of merchandise to your vehicle or truck.

All winning bidders are responsible to hire an insured rigger for the removal of items.

7) All purchases must be removed from the premises in the time allocated, as announced by the auctioneer.

8) A deposit of 25% of purchases will be required of every buyer. The deposit and final payment must be paid for by CASH, CASHIER'S CHECK OR WIRE TRANSFER BEFORE REMOVAL.

Deposits will not be returned if, items are not removed or paid for within the time announced or posted.

9) All buyers shall, at the time of purchase pay any state and local taxes, unless documentation is on file with AAG exempting from such taxes.

10) While quantities and description are believed to be correct, there are no guarantees and the auctioneers, owners, and advertising counsel will not be held responsible for advertising discrepancies, inaccuracies or failure of merchandise to correspond with any standard expected. All lots shall auctioned and bid upon lot number.

11) The auctioneer shall in no event be liable to the purchaser for non delivery of any lot for any reason except for the return to the purchaser of the deposit or money paid on such non delivered lots.

.

ANY ITEMS NOT REMOVED ON OR BEFORE THE REMOVAL DATE SHALL BE DEEMED ABANDONED AND WILL BE REMOVED AND SCRAPPED AT THE BUYERS EXPENSE

12) ALL SALES IN U.S. DOLLARS ONLY

13) If you do not have a credit card to register with bidspotter, then please call our office at 818-763-2021 and make arrangements to overnight checks.

14) PAYMENTS MUST BE MADE OR WIRE INITIATED BY CLOSE OF BUSINESS THE DAY AFTER THE SALE. Credit card authorization and company checks (not accompanied by bank letter) are for deposit only, and in the case of company checks (not accompanied by bank letters), will be returned to customer once full payment in cash, cashier's check or wire transfer is made.

INTERNET BUYERS PREMIUM IS 18%.

ALL SALES TAX WILL BE SUBJECT TO LOCAL SALES TAX.

AAG OFFICE NUMBER IS 818-763-2021

AAG FAX NUMBER IS 818-291-9495

Cash, Cashier check, or Wire transfer ONLY.

Credit Card is required for registrations but cannot be used for purchases.