1

Complete and fully functional Malting facility with 20 ton capacities per month

Complete and fully functional Malting facility with 20 ton capacities per

month ..Offered in “Bulk” only

Malting tanks; (2) stainless steel, food grade, 2-ton, malt tanks custom designed

and built by Ferblanterie Bertrand Turcotte 5 years ago, have seen very limited use.

Each has 2 inner chambers, approximately 5 x 4 x 8 ft., separate product load-out

doors, moveable, hopper, stainless steel lids, each has heated air and water delivery

systems to complete the process. The air and water systems include; USF Fan

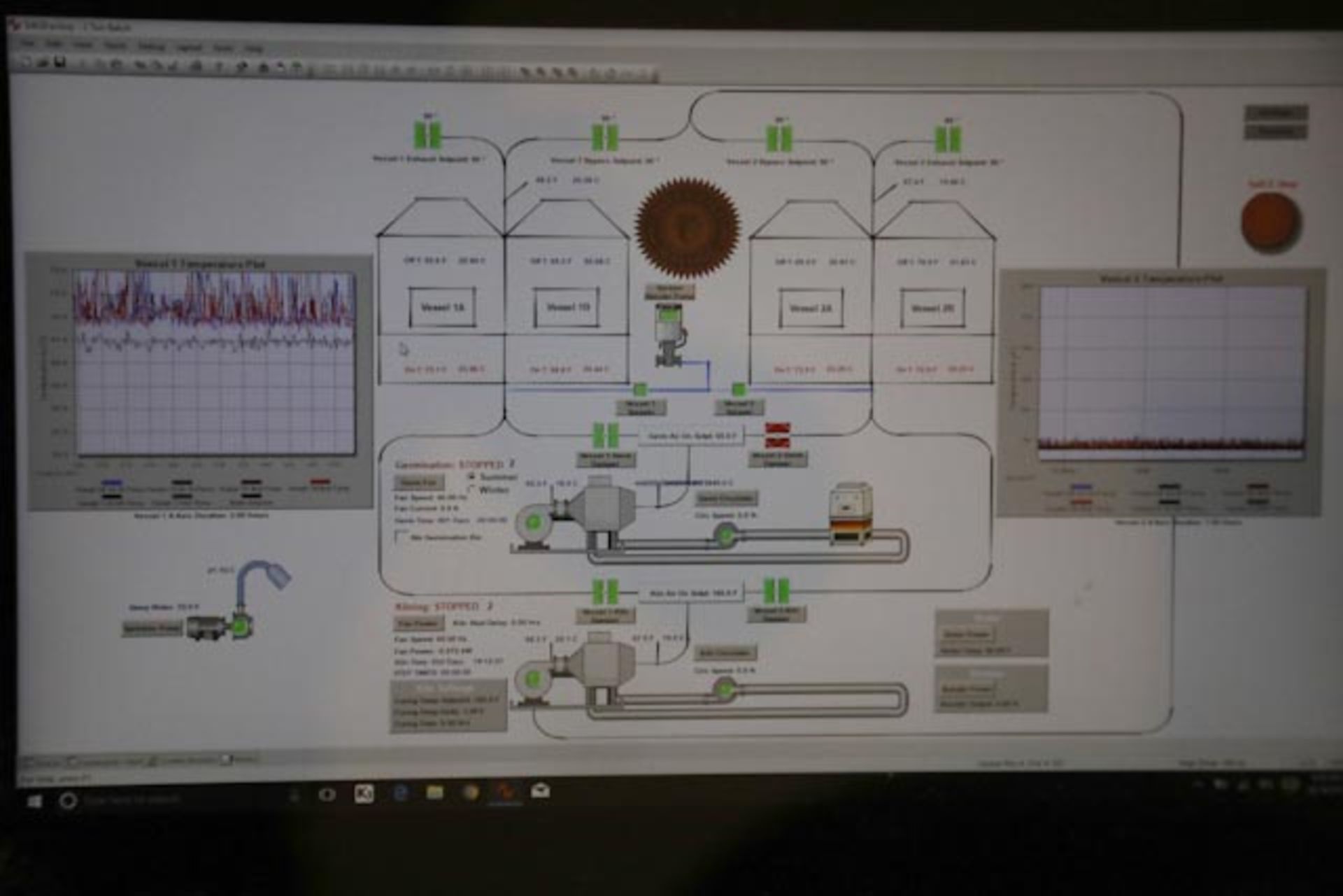

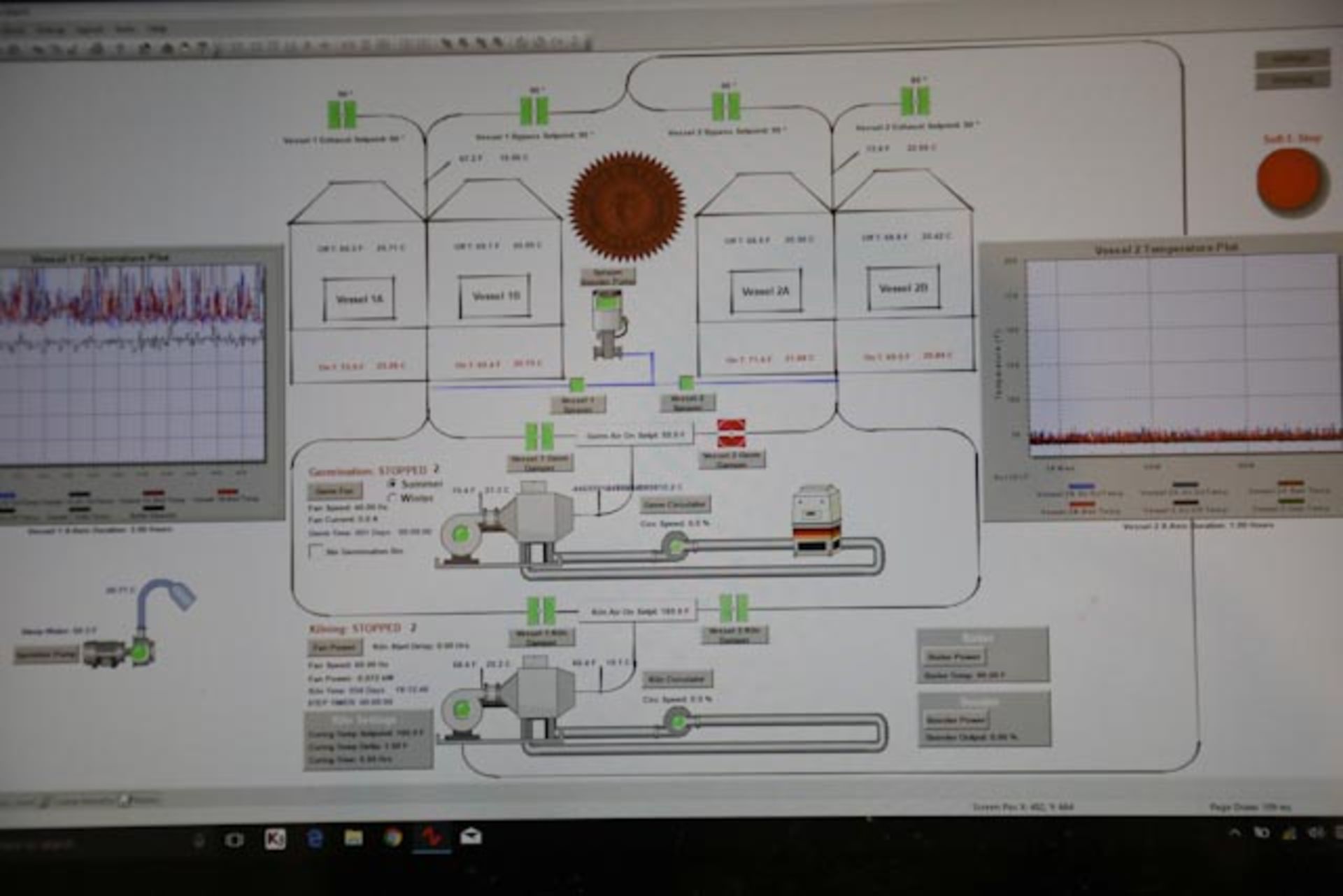

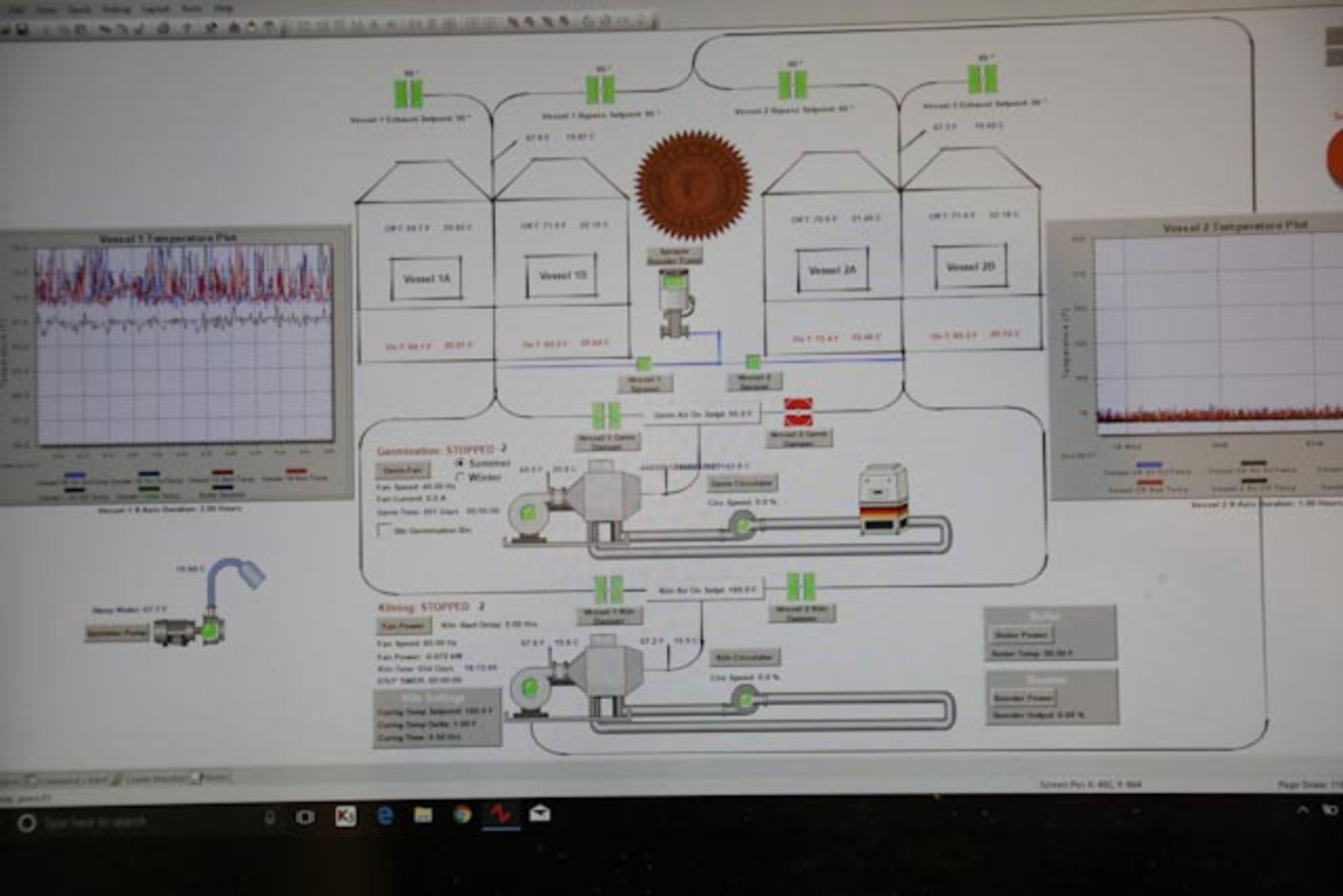

2738 RPM system, an additional air fan system, all controlled by an integrated

computer system that controls the entire malting system.

1-ton malting tank, stainless steel, custom built and designed by Christian Stanley,

1,300 gallon capacity (water), included is a condenser, powered by R-410A and a

Fluidics chiller system, new components, never set up, control panel, new 12” fan,

(2) seed cleaners (early vintage models) with a flex auger and stainless steel

hopper system.

Complete chiller system with expansion tank, Bell & Gossett heat exchanger, 3-

ton chiller on the roof, heat exchanger for the cooling system

Ingersoll Rand R5.5 rotary screw air compressor

2,500 gallon capacity process water storage tank with heating and cooling lines

(the black tank in the picture)

Camus Model Micro Flame Series 2 computerized boiler system with VST

expansion tank, along with an electronic heat exchanger (fully controllable)

Ancillary Equipment:

• Hutchinson portable 30 ft. auger feed system, 220 volt

• Westfield 10 ft. 110 volt portable auger feed system

• Taylor bulk bag filling system with rack system to hold bags

• Digital platform scale

• Fischbein bulk bag sewing device

• 5,500 lb. capacity hydraulic pallet lift

• Eliminator Model 224 seed cleaner

• (7) sections of heavy, commercial, clip-style, industrial pallet racking

• Q-Sage Deculmer

• Ohus moisture meter, sieve system

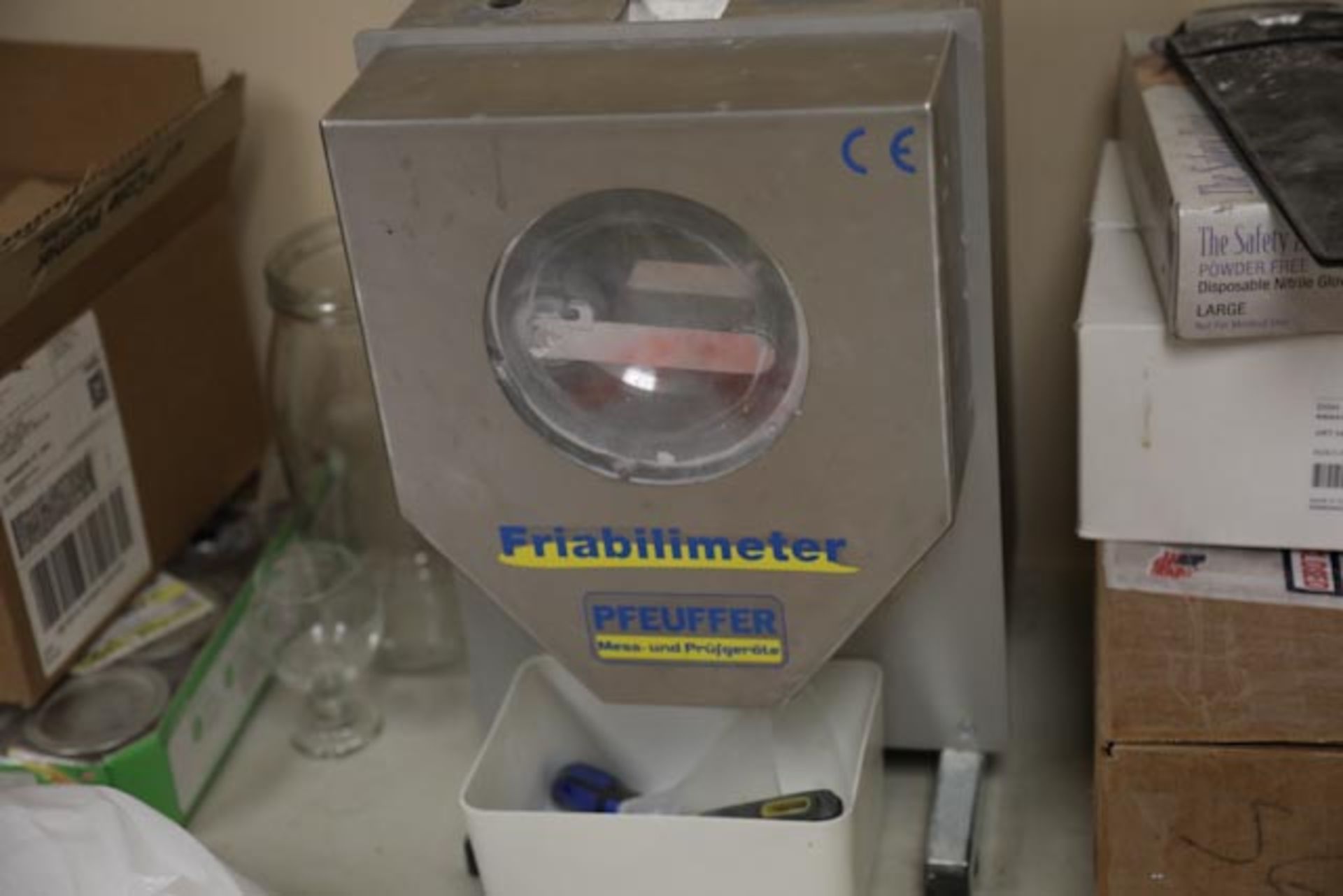

• Friabilimeter Pfeuffer Model HE50 moisture meter system

• Mini-GAC+ grain moisture tester

THIS IS A FULLY FUNCTIONING MALT HOUSE, WITH AN ESTABLISHED BRAND, SOCIAL MEDIA PRESENCE,

FUNCTIONING LAB, BAGGING AND STORING OF OVER 20 SUPER SACKS WITH 20 TON per MONTH

CAPACITY. IT IS COMPUTERIZED AND CONTAINS 2 Turcotte “Custom Designed 2-Ton Mating tanks, 1-

2500 GAL. CONDITIONING TANK TO HEAT AND COOL WATER, INGERSOLL RAND 7.5 HP ROTARY

SCREW COMPRESSOR, 30-TON CHILLER, 1,200 Gallon One ton chiller system, GREENHECK USF FAN,

AND A CAMUS GAS FIRE BOILER FOR HEAT WITH AN ELECTRIC ASSIST. FACILITY IS ON A MONTH TO

MONTH LEASE. BUYER MAY EXTEND TERM AT CURRENT LOCATION OR RELOCATE THE FACILITY, AT

BUYER'S OPTION or Remove the assets from the building.

For more information, please contact: Charles Anderson 716-838-8484

QUEEN CITY MALTING

30 TON CHILLER

2500 GAL. WATER CONDITIONING TANK

2 - TWO-TON STAINLESS STEEL MALT TANKS

GAS FIRED BOILER WATER HEATER

HEAT EXCHANGERS

COMPUTER AND AUTOMATION SOFTWARE

LABRITORY

MB25 OHAUS MOISTURE METER

PFEUFFER FRIABILITY METER

GRAIN MOISTURE PROBES

GRAIN HANDLING

HUTCHINSON AUGER

WESTFIELD AUGER

ELIMINATOR 224 SEED CLEANER WITH 6 SCREENS

TP TAYLOR PRODUCTS MANUAUL BAGGER

LOCOSC LP7620 5,000# CAPACITY SCALE

ADJUSTABLE PALLAT RACKING

BAG STICHER

SUGAR TOWER

QSAGE DECULMER

MISC. EQUIPMENT

PRESURE WASHER

FOOD GRADE SHOVELS

FOOD GRADE BOOTS

HP 8600 PRINTER

Complete and fully functional Malting facility with 20 ton capacities per

month ..Offered in “Bulk” only

Malting tanks; (2) stainless steel, food grade, 2-ton, malt tanks custom designed

and built by Ferblanterie Bertrand Turcotte 5 years ago, have seen very limited use.

Each has 2 inner chambers, approximately 5 x 4 x 8 ft., separate product load-out

doors, moveable, hopper, stainless steel lids, each has heated air and water delivery

systems to complete the process. The air and water systems include; USF Fan

2738 RPM system, an additional air fan system, all controlled by an integrated

computer system that controls the entire malting system.

1-ton malting tank, stainless steel, custom built and designed by Christian Stanley,

1,300 gallon capacity (water), included is a condenser, powered by R-410A and a

Fluidics chiller system, new components, never set up, control panel, new 12” fan,

(2) seed cleaners (early vintage models) with a flex auger and stainless steel

hopper system.

Complete chiller system with expansion tank, Bell & Gossett heat exchanger, 3-

ton chiller on the roof, heat exchanger for the cooling system

Ingersoll Rand R5.5 rotary screw air compressor

2,500 gallon capacity process water storage tank with heating and cooling lines

(the black tank in the picture)

Camus Model Micro Flame Series 2 computerized boiler system with VST

expansion tank, along with an electronic heat exchanger (fully controllable)

Ancillary Equipment:

• Hutchinson portable 30 ft. auger feed system, 220 volt

• Westfield 10 ft. 110 volt portable auger feed system

• Taylor bulk bag filling system with rack system to hold bags

• Digital platform scale

• Fischbein bulk bag sewing device

• 5,500 lb. capacity hydraulic pallet lift

• Eliminator Model 224 seed cleaner

• (7) sections of heavy, commercial, clip-style, industrial pallet racking

• Q-Sage Deculmer

• Ohus moisture meter, sieve system

• Friabilimeter Pfeuffer Model HE50 moisture meter system

• Mini-GAC+ grain moisture tester

THIS IS A FULLY FUNCTIONING MALT HOUSE, WITH AN ESTABLISHED BRAND, SOCIAL MEDIA PRESENCE,

FUNCTIONING LAB, BAGGING AND STORING OF OVER 20 SUPER SACKS WITH 20 TON per MONTH

CAPACITY. IT IS COMPUTERIZED AND CONTAINS 2 Turcotte “Custom Designed 2-Ton Mating tanks, 1-

2500 GAL. CONDITIONING TANK TO HEAT AND COOL WATER, INGERSOLL RAND 7.5 HP ROTARY

SCREW COMPRESSOR, 30-TON CHILLER, 1,200 Gallon One ton chiller system, GREENHECK USF FAN,

AND A CAMUS GAS FIRE BOILER FOR HEAT WITH AN ELECTRIC ASSIST. FACILITY IS ON A MONTH TO

MONTH LEASE. BUYER MAY EXTEND TERM AT CURRENT LOCATION OR RELOCATE THE FACILITY, AT

BUYER'S OPTION or Remove the assets from the building.

For more information, please contact: Charles Anderson 716-838-8484

QUEEN CITY MALTING

30 TON CHILLER

2500 GAL. WATER CONDITIONING TANK

2 - TWO-TON STAINLESS STEEL MALT TANKS

GAS FIRED BOILER WATER HEATER

HEAT EXCHANGERS

COMPUTER AND AUTOMATION SOFTWARE

LABRITORY

MB25 OHAUS MOISTURE METER

PFEUFFER FRIABILITY METER

GRAIN MOISTURE PROBES

GRAIN HANDLING

HUTCHINSON AUGER

WESTFIELD AUGER

ELIMINATOR 224 SEED CLEANER WITH 6 SCREENS

TP TAYLOR PRODUCTS MANUAUL BAGGER

LOCOSC LP7620 5,000# CAPACITY SCALE

ADJUSTABLE PALLAT RACKING

BAG STICHER

SUGAR TOWER

QSAGE DECULMER

MISC. EQUIPMENT

PRESURE WASHER

FOOD GRADE SHOVELS

FOOD GRADE BOOTS

HP 8600 PRINTER

QUEEN CITY MALTING FACILITY

Ends from

Venue Address

For Anderson Auction & Realty delivery information please telephone 716 838 8484.

Important Information

BidSpotter Customer Service Support Department

To reach a member of our qualified support staff regarding information or questions pertaining to the bidding process; please reach us by phone or email.

- Available Monday – Friday, 8:00am – 11:00 PM ET.

- Email: Support@bidspotter.com

- Office: 253-858-6777

- Frequently Asked Questions

Terms and Conditions

Terms of sale:

The assets will be sold subject to approval by the owner. Approval will be within 24 hours of the completion of the sale. The buyer will have 5 working days to pay for the plant in full. NYS sales tax will be charged if the successful purchaser is from NYS unless an exempt use certificate is presented to the seller. After payment in full the buyer can carefully remove the assets not damaging the building, and leave the premises in clean condition. A proposal to remove the assets and load onto your trailers is in the detail section of the sale data. The premises is also available to lease if you would like to keep the assets in place and operational.

Purchasers from outside of NYS will not be charged sales tax if the assets are removed by common carrier with a bill of lading which must be provided to the seller.