197

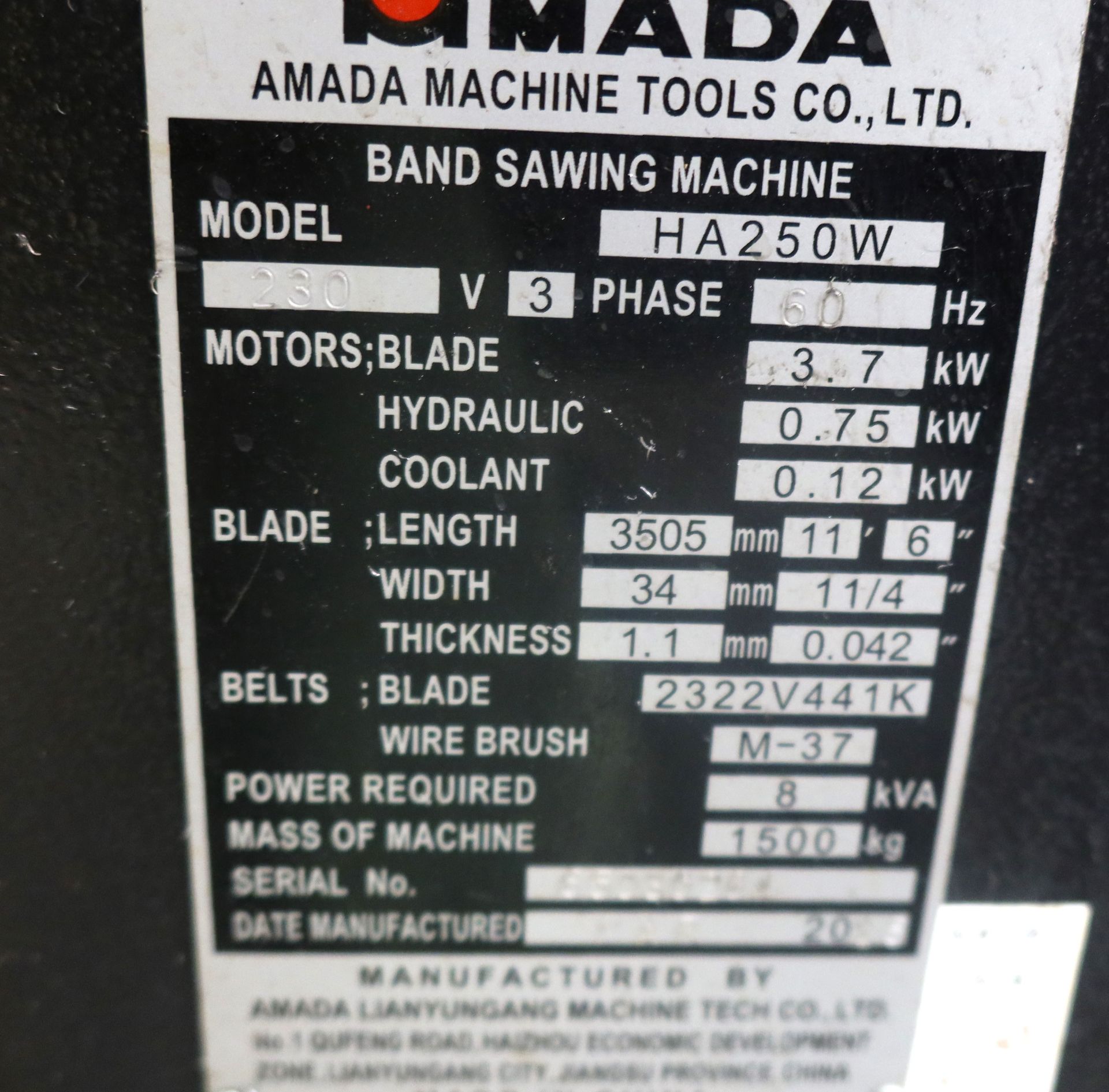

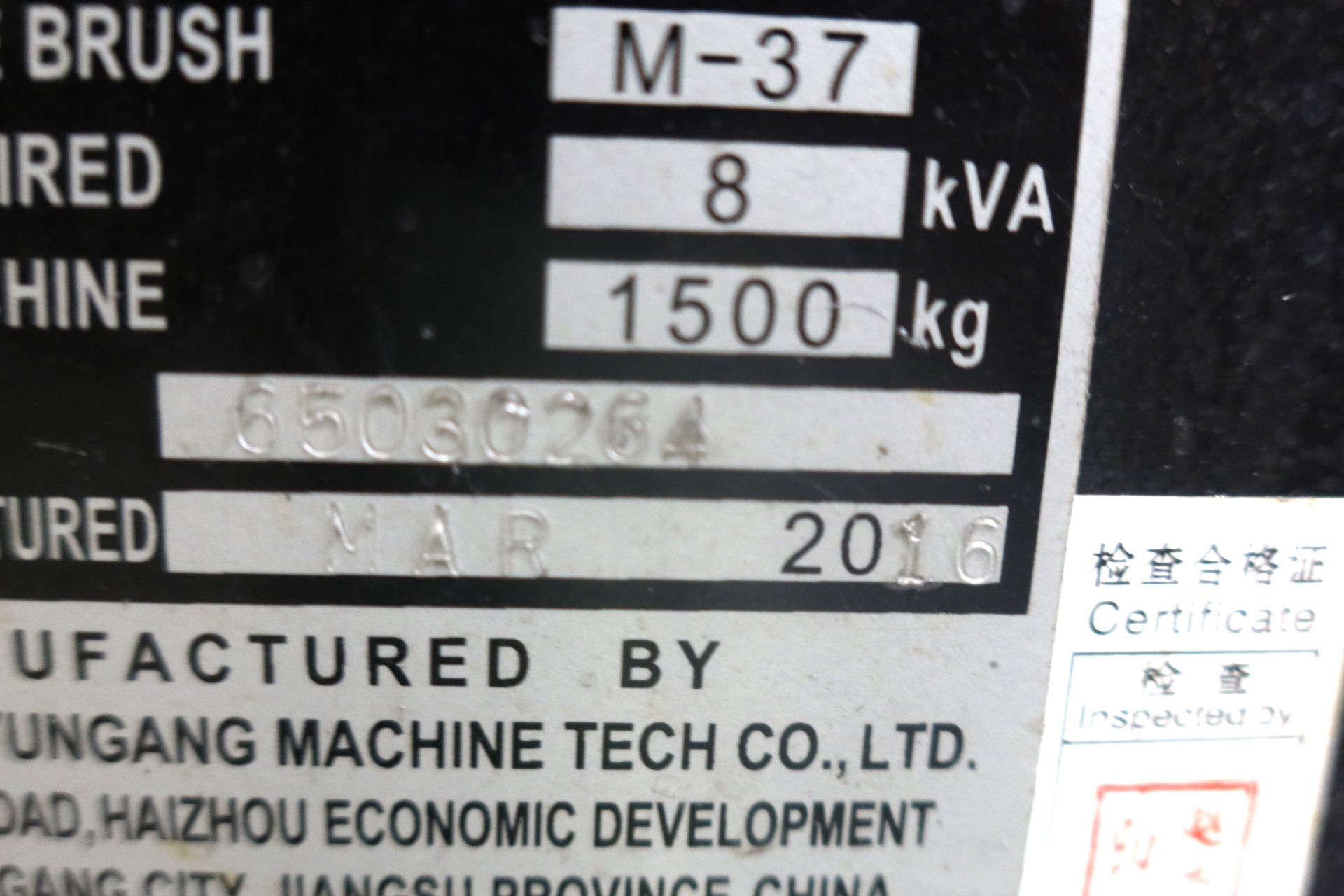

2016 Amada HA250W Automatic Horizontal Band Saw SN 65030264

| SPECIFICATIONS Model HA250W Cutting Capacity Round (Diameter) 1.18″ – 10“ 30 – 250 mm Rectangle (W x H) 11.8″ x 10″ 300 x 250 mm Work Load Capacity 3,307 lbs. 1,500 kg Saw Blade Blade Size (L x T x W) 11’6″ x 0.042″ x 1-1/4″ 3505 x 1.1 x 34 mm Blade Speed 89-295 ft./min, 60 Hz Stepless 27-90 m/min, 60 Hz Stepless Tension Control Hydraulic Blade Control Top Limit Setting Automatic Setting with Quick Approach Feeler Cutting Control Hydraulic Pressure-Flow Control Valve Vise Operation Type Main Split Vise and Rear Vise Control Hydraulic Full-Stroke Cylinder Motors Saw Blade 5 HP 3.7 kW Hydraulic Pump 1 HP 0.75 kW Cutting Fluid Pump 1/4 HP 0.12 kW Power Requirement Power Supply Voltage AC220V±10%, 3 PH, 60 Hz or AC440V±10%, 3 PH, 60 Hz Power Requirement 8 kVA Cutting Fluid Tank Capacity 22.5 gal 85 liters Pump Type Centrifugal Electric Pump Capacity 5.3 gal/min 20 L/min Hydraulic Tank Capacity 7.9 gal 30 liters Pump Type Variable Discharge Vane Electric Pump Pump Capacity 4.0 gal/min 15 L/min Pressure Setting 384 psi 2.7 MPa (58 kgf/cm2) Chip Disposal Chip Conveyor Material Index Index Mechanism Shuttle Vise Stroke 15.75″ (Maximum 9 times index) Length 0.394″-141.7″ 10.0-3600 mm Number of Input Station 1 Number of Cut-Off Pieces 1-9999 Remnant Length 2.24″ Plus Length of Parts 57 mm Plus Length of Parts Machine Dimensions (W x L x H) Head-Up Position 76.5″ x 93.1″ x 69.8″ 1945 x 2366 x 1772 mm Head Down Position 76.5″ x 93.1″ x 50.6″ 1945 x 2366 x 1285 mm Table Height 27.6″ 700 mm Machine Weight 3,307 lbs 1,500 kg FEATURES § Saw Head Frame o The rigid ‘C’ section frame carries the mountings for the two band wheels, heavy-duty worm drive gear reducer, the band drive motor, and saw guide arm mounting supports. § Band Wheels & Drive System o The band wheels are cast iron for long, productive life. The deflection free 1.38 inch (35 mm.) wheel spindles ensure the wheels run true regardless of tension stress or cutting loads. The spindle assemblies incorporate tapered roller bearings for greater rigidity and long service life. The wheel tracks the blade so that the back of the band is contacts the wheel flanges to support the band. The drive motor is coupled to the transmission through a variable speed pulley. § Drive Wheel Transmission o The drive wheel transmission is designed and built by Amada to provide high efficiency speed reduction, which requires no external cooling, to deliver more power to the large diameter drive shaft. This shaft ensures that this developed torque is transferred to the blade with no strobing, enabling the machine to efficiently cut high alloys as well as free machining materials. § Pressure/Flow Feed Control o The independent pressure and flow controls in series ensure the optimum cutting rate can be obtained regardless of section or alloy being cut. The pressure control determines the cutting force applied to the blade and the flow control sets the maximum fall rate of the head. For example for difficult to machine materials the pressure is set higher than free machining alloys and the flow is set lower, as shown on the escutcheons above the above the control knobs. § Idler Wheel Motion Detector o The wheel motion detector will turn off the blade drive in the case where a blade breaks or is jammed in the work piece. This feature also prevents premature wear on the drive wheel from a stalled band. § Automatic, Powered Chip Conveyor o The electrically powered chip conveyor auger automatically removes the saw chips from the saw while draining the cutting fluid back into the fluid reservoir. The automatic chip conveyor greatly reduces cleanup time and enables the machine to run longer without operator cleanup. § Multiple Index § o The machine control has the capability to make up to 9 index passes giving a maximum cut length of 141.7 in. (3,600 mm.) in automatic. § Split Front Vise o The work holding vise is split so that it clamps the workpiece on both sides of the cutting plane. This additional support in front of the cutting plane minimizes the burr on the cut pieces. |

| SPECIFICATIONS Model HA250W Cutting Capacity Round (Diameter) 1.18″ – 10“ 30 – 250 mm Rectangle (W x H) 11.8″ x 10″ 300 x 250 mm Work Load Capacity 3,307 lbs. 1,500 kg Saw Blade Blade Size (L x T x W) 11’6″ x 0.042″ x 1-1/4″ 3505 x 1.1 x 34 mm Blade Speed 89-295 ft./min, 60 Hz Stepless 27-90 m/min, 60 Hz Stepless Tension Control Hydraulic Blade Control Top Limit Setting Automatic Setting with Quick Approach Feeler Cutting Control Hydraulic Pressure-Flow Control Valve Vise Operation Type Main Split Vise and Rear Vise Control Hydraulic Full-Stroke Cylinder Motors Saw Blade 5 HP 3.7 kW Hydraulic Pump 1 HP 0.75 kW Cutting Fluid Pump 1/4 HP 0.12 kW Power Requirement Power Supply Voltage AC220V±10%, 3 PH, 60 Hz or AC440V±10%, 3 PH, 60 Hz Power Requirement 8 kVA Cutting Fluid Tank Capacity 22.5 gal 85 liters Pump Type Centrifugal Electric Pump Capacity 5.3 gal/min 20 L/min Hydraulic Tank Capacity 7.9 gal 30 liters Pump Type Variable Discharge Vane Electric Pump Pump Capacity 4.0 gal/min 15 L/min Pressure Setting 384 psi 2.7 MPa (58 kgf/cm2) Chip Disposal Chip Conveyor Material Index Index Mechanism Shuttle Vise Stroke 15.75″ (Maximum 9 times index) Length 0.394″-141.7″ 10.0-3600 mm Number of Input Station 1 Number of Cut-Off Pieces 1-9999 Remnant Length 2.24″ Plus Length of Parts 57 mm Plus Length of Parts Machine Dimensions (W x L x H) Head-Up Position 76.5″ x 93.1″ x 69.8″ 1945 x 2366 x 1772 mm Head Down Position 76.5″ x 93.1″ x 50.6″ 1945 x 2366 x 1285 mm Table Height 27.6″ 700 mm Machine Weight 3,307 lbs 1,500 kg FEATURES § Saw Head Frame o The rigid ‘C’ section frame carries the mountings for the two band wheels, heavy-duty worm drive gear reducer, the band drive motor, and saw guide arm mounting supports. § Band Wheels & Drive System o The band wheels are cast iron for long, productive life. The deflection free 1.38 inch (35 mm.) wheel spindles ensure the wheels run true regardless of tension stress or cutting loads. The spindle assemblies incorporate tapered roller bearings for greater rigidity and long service life. The wheel tracks the blade so that the back of the band is contacts the wheel flanges to support the band. The drive motor is coupled to the transmission through a variable speed pulley. § Drive Wheel Transmission o The drive wheel transmission is designed and built by Amada to provide high efficiency speed reduction, which requires no external cooling, to deliver more power to the large diameter drive shaft. This shaft ensures that this developed torque is transferred to the blade with no strobing, enabling the machine to efficiently cut high alloys as well as free machining materials. § Pressure/Flow Feed Control o The independent pressure and flow controls in series ensure the optimum cutting rate can be obtained regardless of section or alloy being cut. The pressure control determines the cutting force applied to the blade and the flow control sets the maximum fall rate of the head. For example for difficult to machine materials the pressure is set higher than free machining alloys and the flow is set lower, as shown on the escutcheons above the above the control knobs. § Idler Wheel Motion Detector o The wheel motion detector will turn off the blade drive in the case where a blade breaks or is jammed in the work piece. This feature also prevents premature wear on the drive wheel from a stalled band. § Automatic, Powered Chip Conveyor o The electrically powered chip conveyor auger automatically removes the saw chips from the saw while draining the cutting fluid back into the fluid reservoir. The automatic chip conveyor greatly reduces cleanup time and enables the machine to run longer without operator cleanup. § Multiple Index § o The machine control has the capability to make up to 9 index passes giving a maximum cut length of 141.7 in. (3,600 mm.) in automatic. § Split Front Vise o The work holding vise is split so that it clamps the workpiece on both sides of the cutting plane. This additional support in front of the cutting plane minimizes the burr on the cut pieces. |

High End 5-Axis CNC Machines: Surplus to the ongoing operations of a defense Mfg. MVB Industries Inc

Ends from

Venue Address

Small Items must be removed by Monday, June 19, 2023 – Final removal “No Exceptions” Thursday, June 29, 2023 by 4:00 PM. For complete removal and sale terms, please reference the Terms and Condition section of this auction. Approved Exclusive Rigger Pedowitz Machinery Movers Eunice Garcia (561-564-8756) Office 954-973-9737 Email: Eunice@pedowitz.com

Important Information

=========================================

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Friday, 8:00 AM EST – 8:00 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

Terms & Conditions

- IDENTIFICATION: All Participants are required to register prior to becoming an Approved Bidder. All Participants are required to give full name, permanent street address, phone numbers, email address, valid credit card and business name. Subsequent to registration on BidSpotter, approval to bid is at our discretion.

a. DEPOSITS: INTERNATIONAL BUYERS may be asked to submit a refundable deposit.

2. PAYMENT: Invoices must be paid in full by Monday June 19, 2023. Payment may be made by wire transfer, company check with a bank letter of guarantee, certified funds or cash. (No Credit Cards are accepted) A BUYERS FEE OF 18% WILL BE APPLIED TO INVOICE IN ADDITION TO THE SALES PRICE. Where required by law, ANY APPLICABLE SALES TAX WILL BE APPLIED TO ALL SALES UNLESS BUYER HAS A PROPER EXEMTION. NO MERCHANDISE WILL BE RELEASED UNITIL INVOICE IS PAID IN FULL.

3. Purchase of any lot is at the Purchaser's risk with risk of loss immediately passing to Purchaser upon the auctioneer's call. Neither Premier Asset Recovery Group, LLC, nor its consignors, have any liability of any nature whatsoever to Purchaser if the lot is not delivered to Purchaser due to fire, theft, damage, or any other cause.

4. REMOVAL: All purchases MUST be removed as herein listed. Small items (Tooling, Machine Parts & Accessories, etc.) are to be REMOVED WITHIN 2 DAYS OF THE AUCTION (Friday June 16 8am-4pm and Saturday June 17 8am-2pm). WE ASSUME NO RESPONSIBILITY FOR SMALL, CARRIABLE ITEMS LEFT ON PREMISES ONE DAY AFTER SALE. All other Machinery & Equipment must be removed by, FINAL REMOVAL "NO EXCEPTIONS" THRUSDAY JUNE 29, 2023 BY 4:00 PM

5. Purchases may be removed only on presentation of paid bill. Removal shall be at the expense, risk and liability of the purchaser. Auctioneer shall not be responsible for goods not removed within the time allowed.

6. CONDITION: All Items are sold on “as is – where is”, “in place”, “with all faults” basis no conditions or warranties or representation, written or oral, is given with any lot. All statements contained in Premier Asset Recovery, LLC catalog, website, and marketing material or by the auctioneers, or in any bill of sale, invoice or elsewhere as to description, size, quantity, quality, capacity, model, serial number, measurements or condition, are approximated statements and shall not be deemed to be representations or warranties, oral or written, with respect to any lot. No sale is invalid or made void by reason of any flaw in a lot or by reason of a lot being incorrectly described. Description and Photos are not guaranteed.

It is the buyer’s responsibility to inspect before biding. Premier Asset Recovery Group assumes no liability for error or omissions associated with the auction sale. The buyer does hereby assume and does agree to indemnify and hold the auctioneer and seller harmless from any future claim which shall pertain the fitness or use of the assets being purchased.

7. CLAIMS: NO CLAIMS WILL BE ALLOWED AFTER REMOVAL OF GOODS FROM PREMISES OR LEFT ON PREMISES PAST ALLOWED TIME LIMIT.

8. RESPONSIBILITY FOR NON-DELIVERY: Neither the auctioneer nor the seller, in any event, shall be liable for non-delivery or for any other matter or thing, to any purchaser of any lot, other than for the return to the purchaser of the deposit or sum paid on said lot, should the purchaser be entitled hereto.

9. COMPLIANCE WITH TERMS OF SALE: In default of payment of bills in full within the time therein specified, the auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of resale including legal fees, will be charged to the defaulting purchaser.

10. RISK TO PERSON AND PROPERTY: Persons attending during exhibition, sale or removal of goods assume all risks of damage of or loss to person and property and specifically release the auctioneer and seller from liability therefore. Neither the auctioneer nor his principal shall be liable by reason of any defect in or condition of the premises on which the sale is held.

11. CONTRACT MOVERS: If purchaser wishes to hire or contract with a machinery mover, rigger or other type of outside contractor, PROPER INSURANCE protecting Premier Asset Recovery Group, LLC and the people or company that the auctioneers are conducting the sale for against any or all claims arising from personal injury and/or property damage created by their actions. This requirement is for the auctioneer`s protection - NOT FOR THE PURCHASER`S therefore the auctioneer suggests that the purchaser review the insurance policies of the machinery mover regarding the coverage that they have protecting the purchaser and damage or loss of the equipment they may be moving for the purchaser.

12. ADDITION TO OR WITHDRAWAL FROM SALE: The auctioneer reserves the right to withdraw from sale any of the property listed or to sell at this sale property not listed, and also reserves the right to group one or more lots into one or more selling lots or to subdivide into two or more selling lots. Whenever the best interest of the seller will be served, the auctioneer reserves the right to sell all the property listed, in bulk.

13. It is the Purchaser’s sole responsibility to meet all governmental safety and environmental standards in removing, shipping and using purchased items. Certain of the items for sale may contain “hazardous substances”, as that term is defined under federal, state or local environmental laws and regulations. Premier has no duty to remove any hazardous substances that are contained in or are a part of any items. Purchasers agree to defend (by counsel satisfactory to Premier) and indemnify Premier and hold Premier harmless from any against any claim. Demand, cause of action, liability or expense (including attorney’s fees and costs) asserted against or incurred by Premier in connection with the sale, removal, shipment, or use of any purchased items.

Export: Buyer is responsible to obtain proper licenses, where required for the export of any items that are considered controlled commodities and which are restricted from export outside of the United States without proper export licenses. Buyer further agrees to fully comply with all applicable export control laws, regulations, rules, and orders of the United States and all other applicable jurisdictions, and will not export, re-export, release, or transfer (collectively "export"). directly or indirectly, any Equipment, or enter into any transactions, for any proscribed end-use, or to or with any proscribed end-use, or to or with any proscribed country, entity, or person (wherever located), including but not limited to those entities and persons listed on the U.S. Government's Denied Persons List, Unverified List, Entity List, Debarred Parties List or Specially Designated National List, without first obtaining at its own expense written authorization for the U.S. Government. Agent will have the right to cancel any sale at any time in the event it determines, in its sole discretion, that the sale does or may violate applicable U.S. Export Control or similar laws.

14. DISPUTE BETWEEN BIDDERS: The auctioneer`s decision will be final and absolute.

15. RECORDS: The record of sale kept by the auctioneer and bookkeeper will be taken as final in the event of any dispute.

16. INDEPENDENT CONTRACTOR: The auctioneer is acting as an independent contractor only and is not responsible for the acts of its principals or sellers.

17. ADDITIONAL TERMS AND CONDITIONS: The auctioneer may add other terms and conditions of sale, such additional terms and conditions to be announced prior to the auction.

18. RESERVE: The auctioneer reserves the right to reject any and all bids. On lots upon which there is a reserve, the auctioneer or his assigned agents, shall have the right to bid on behalf of the seller. This Auction Company has requested and been granted access to see all bids placed including any maximum pre-bids. This auction is permitted to engage in this activity by providing this clear disclosure to you, the bidder.

19 These terms and conditions, and all questions with respect to the interpretation of these Terms and Conditions, shall be governed by and construed in accordance with the internal law of the State of Illinois, without regard to conflict of law’s provisions. All bidders expressly consent to personal and exclusive jurisdiction in the courts of the State of Illinois located in Cook County.