10

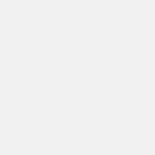

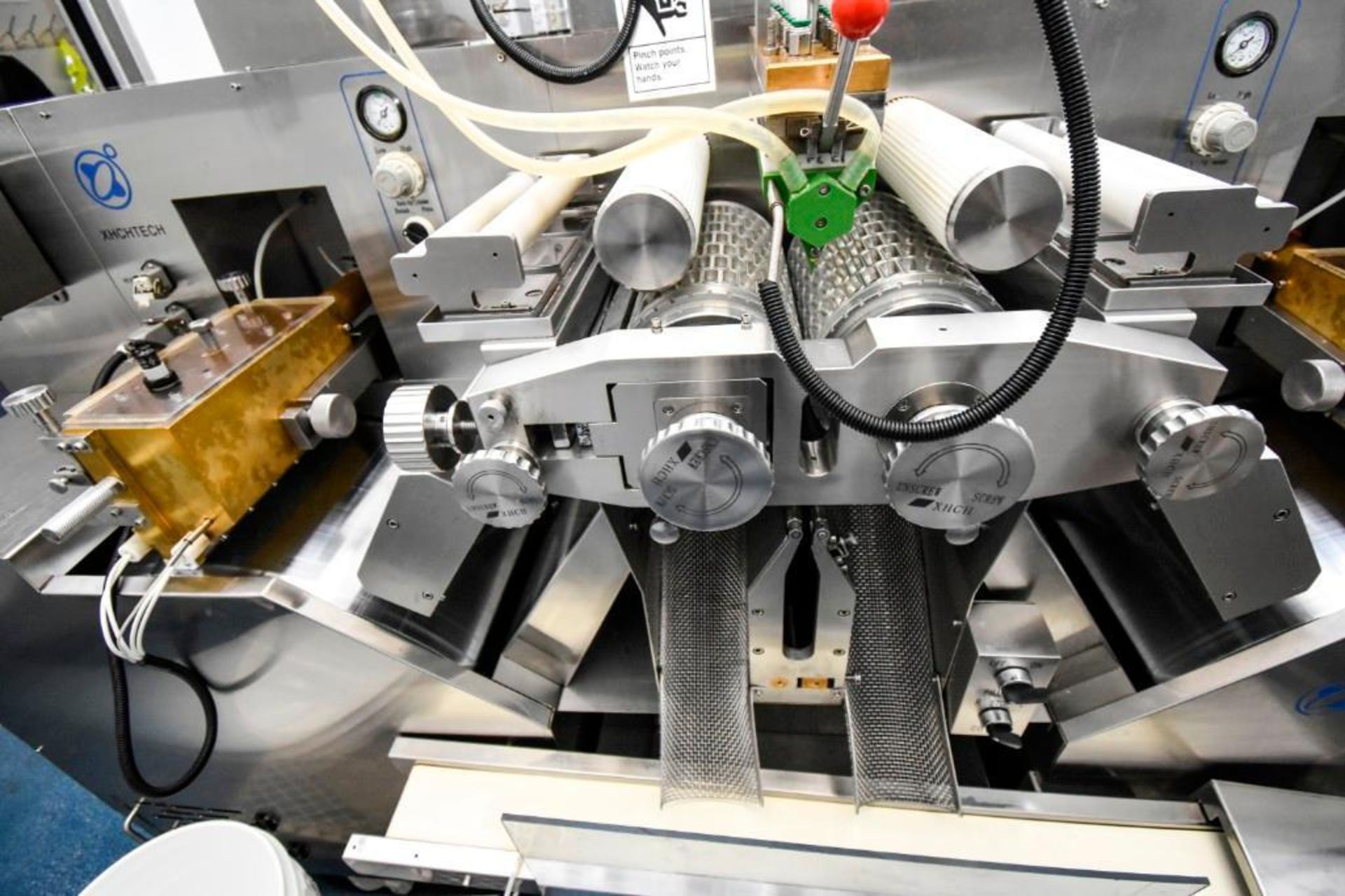

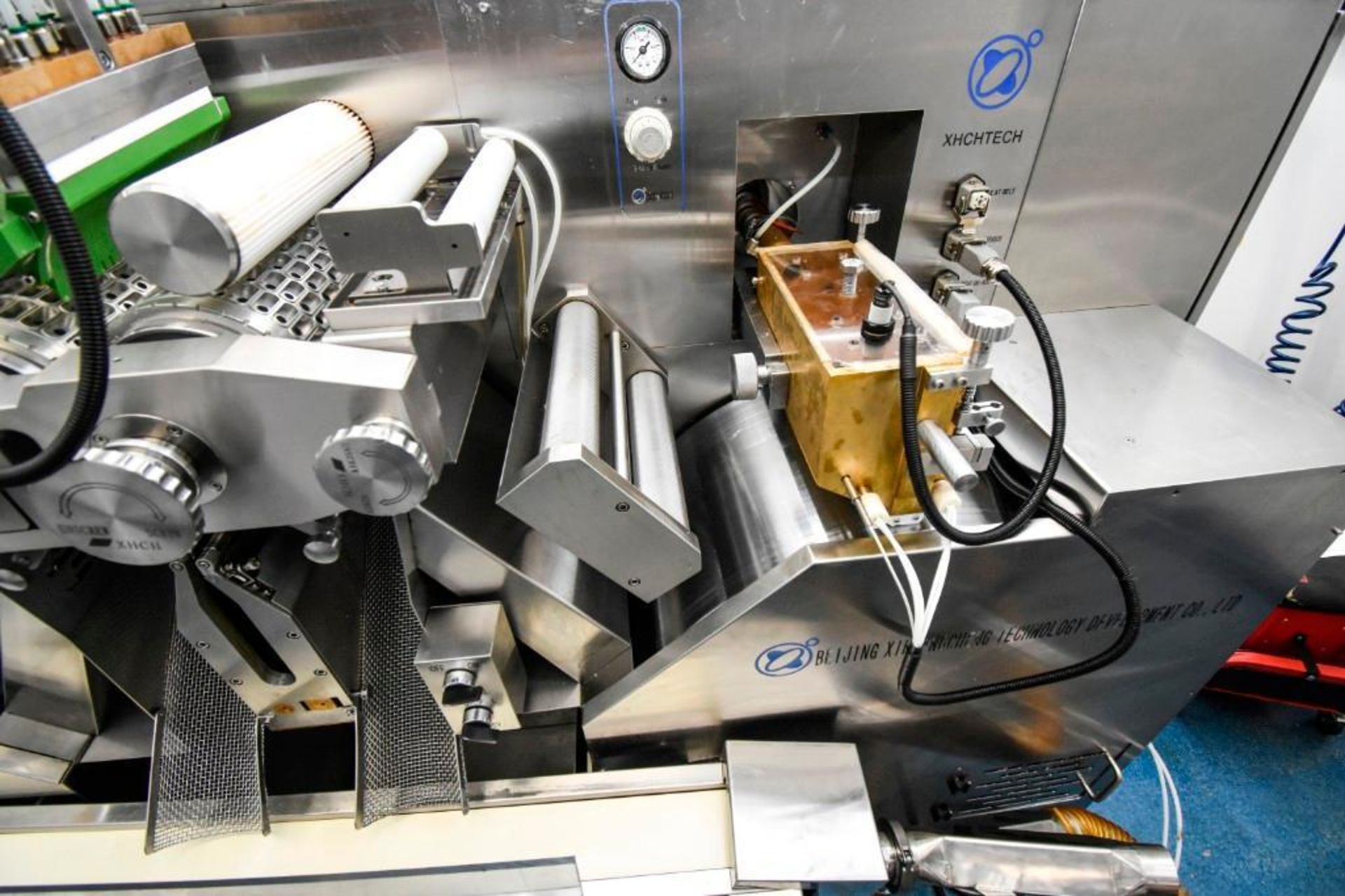

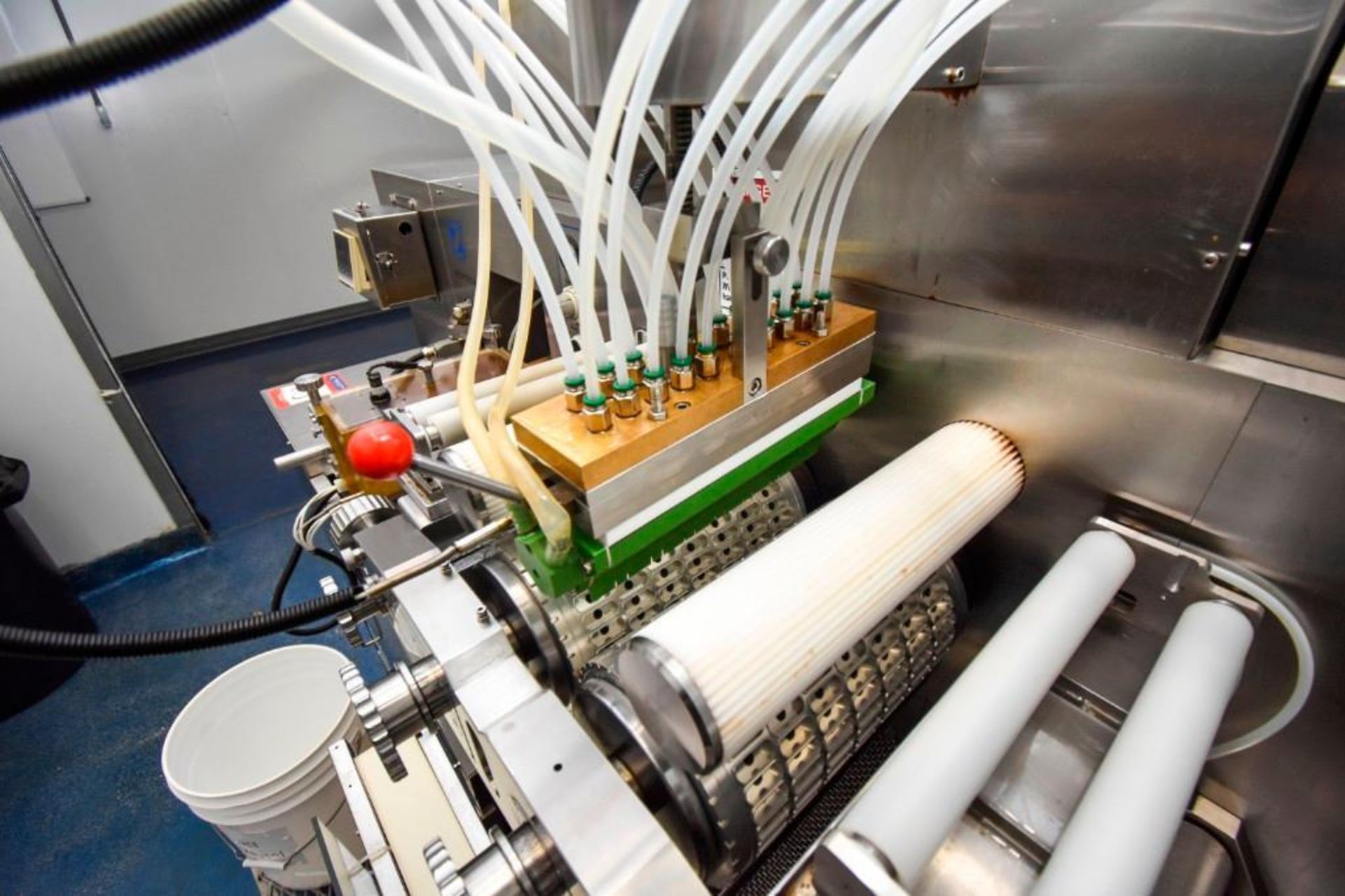

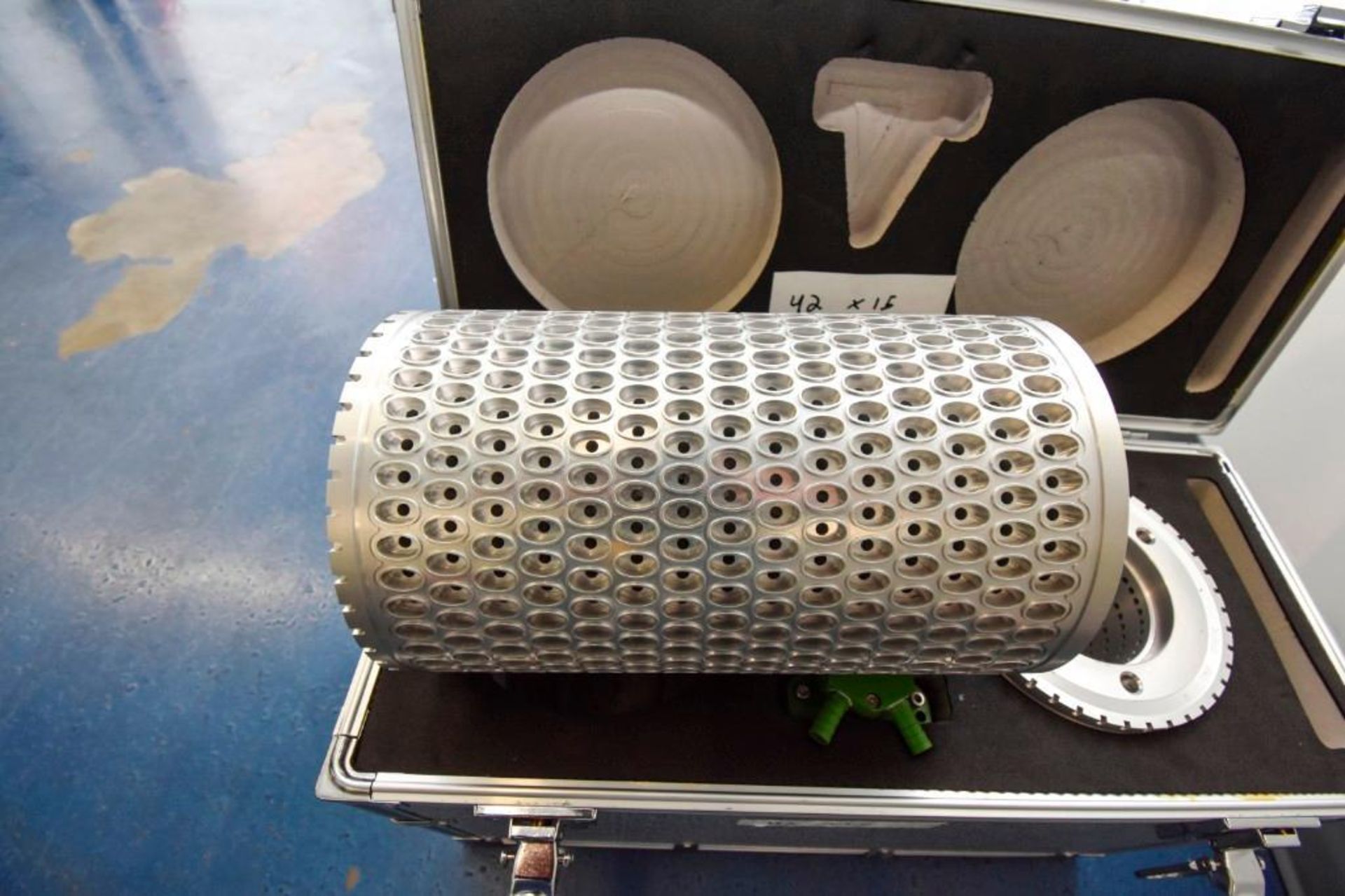

YWJ250-IIIA Fully Automatic High-Speed Softgel Capsule Machine

1- YWJ250-IIIA Fully Automatic High-Speed Softgel Capsule Machine

YWJ250-IIIA fully automatic high-speed soft capsule machine is a new generation of soft capsule production equipment developed by our company based on our company's many years of experience in soft capsule technology. This equipment is technologically advanced, has a simple and beautiful appearance, and is technically stable.

Equipment technical parameters:

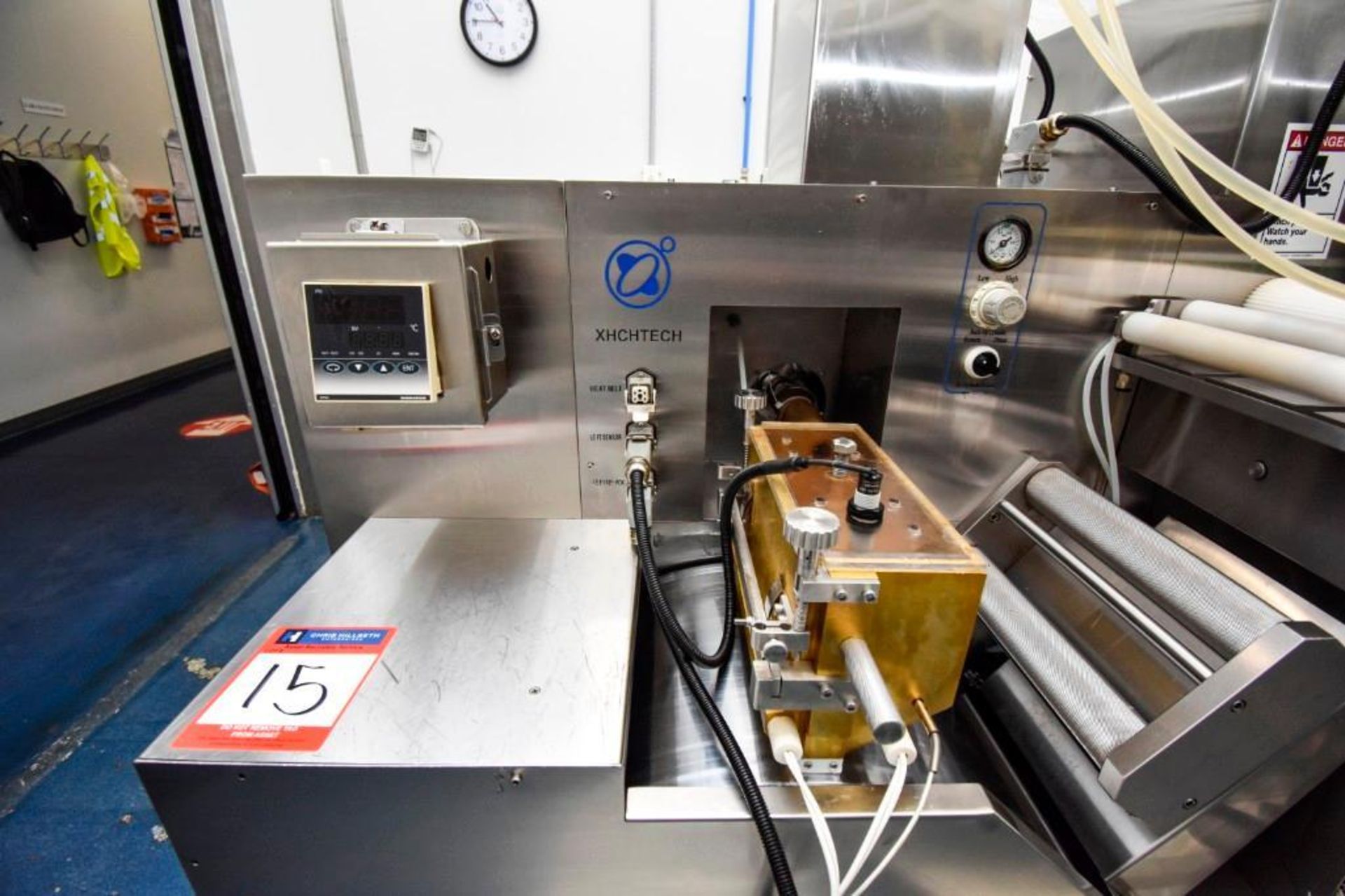

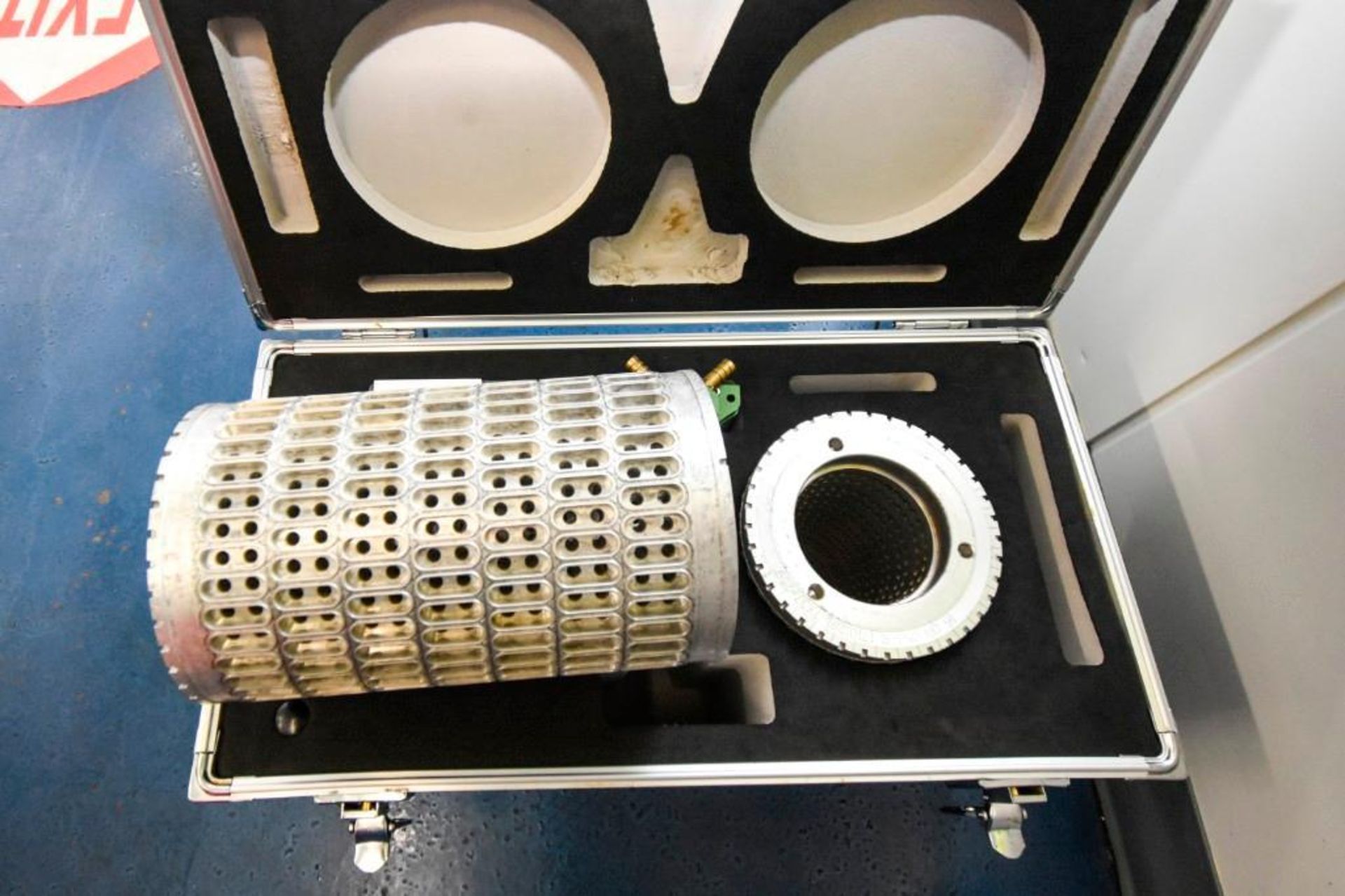

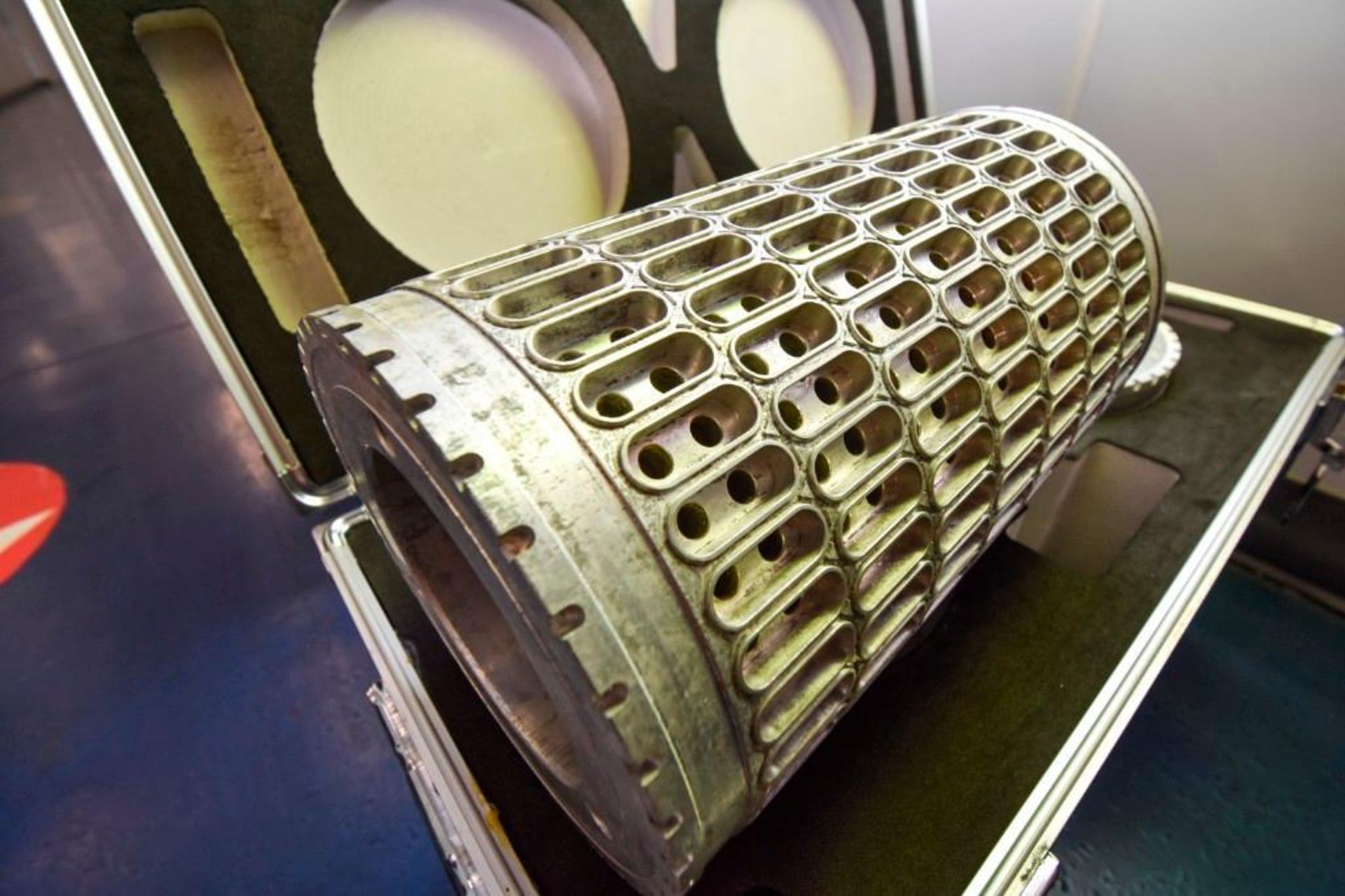

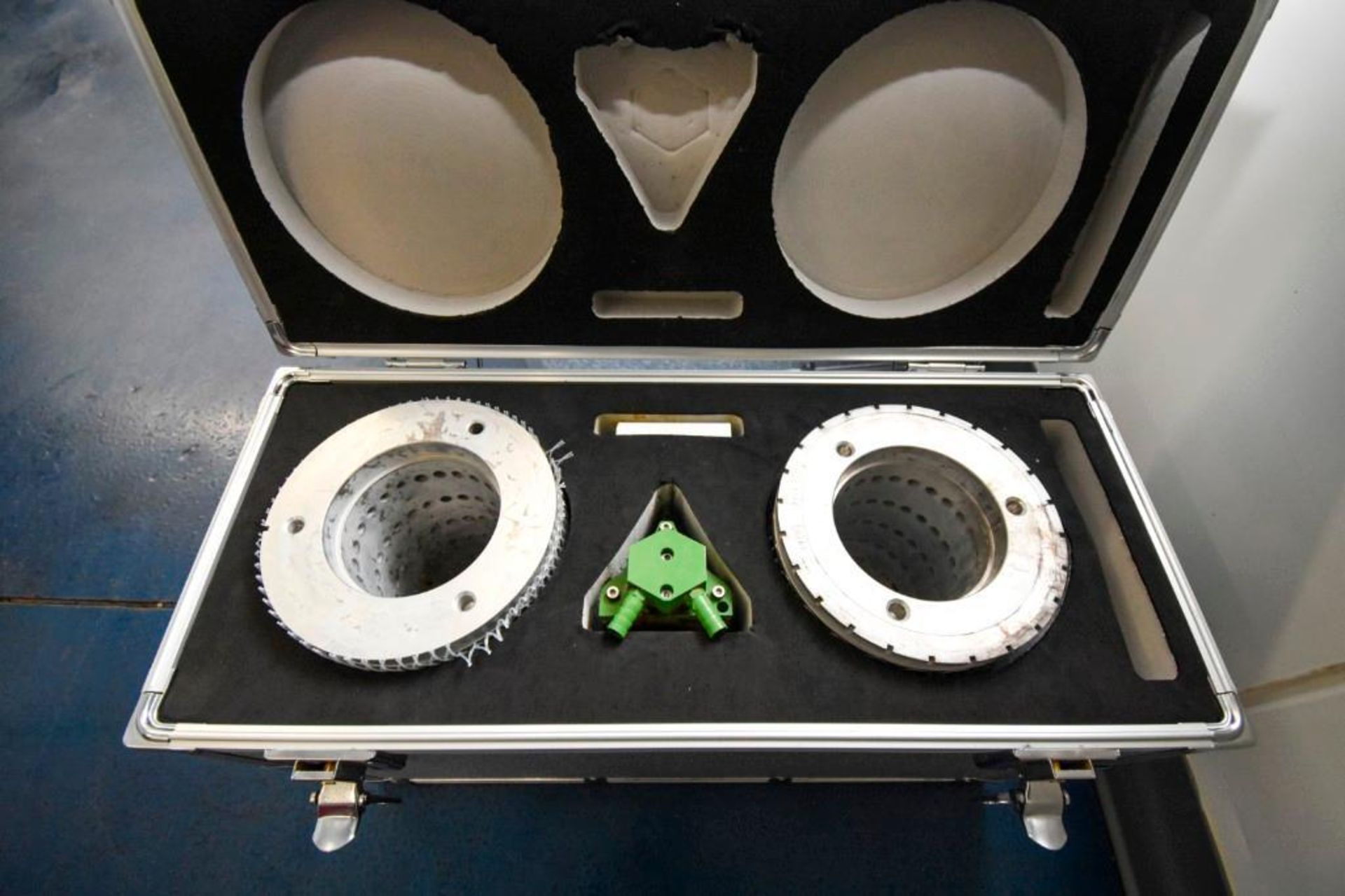

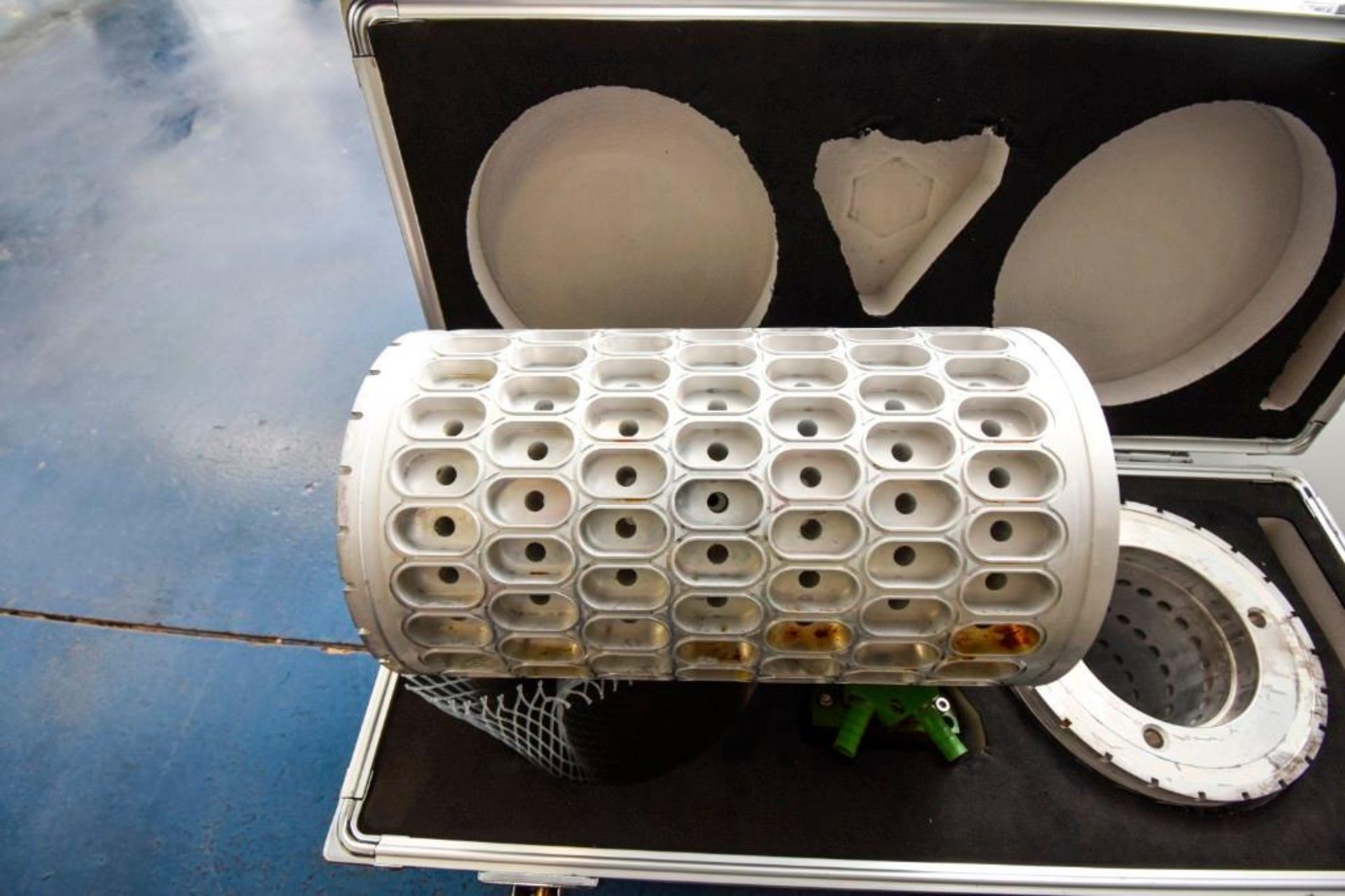

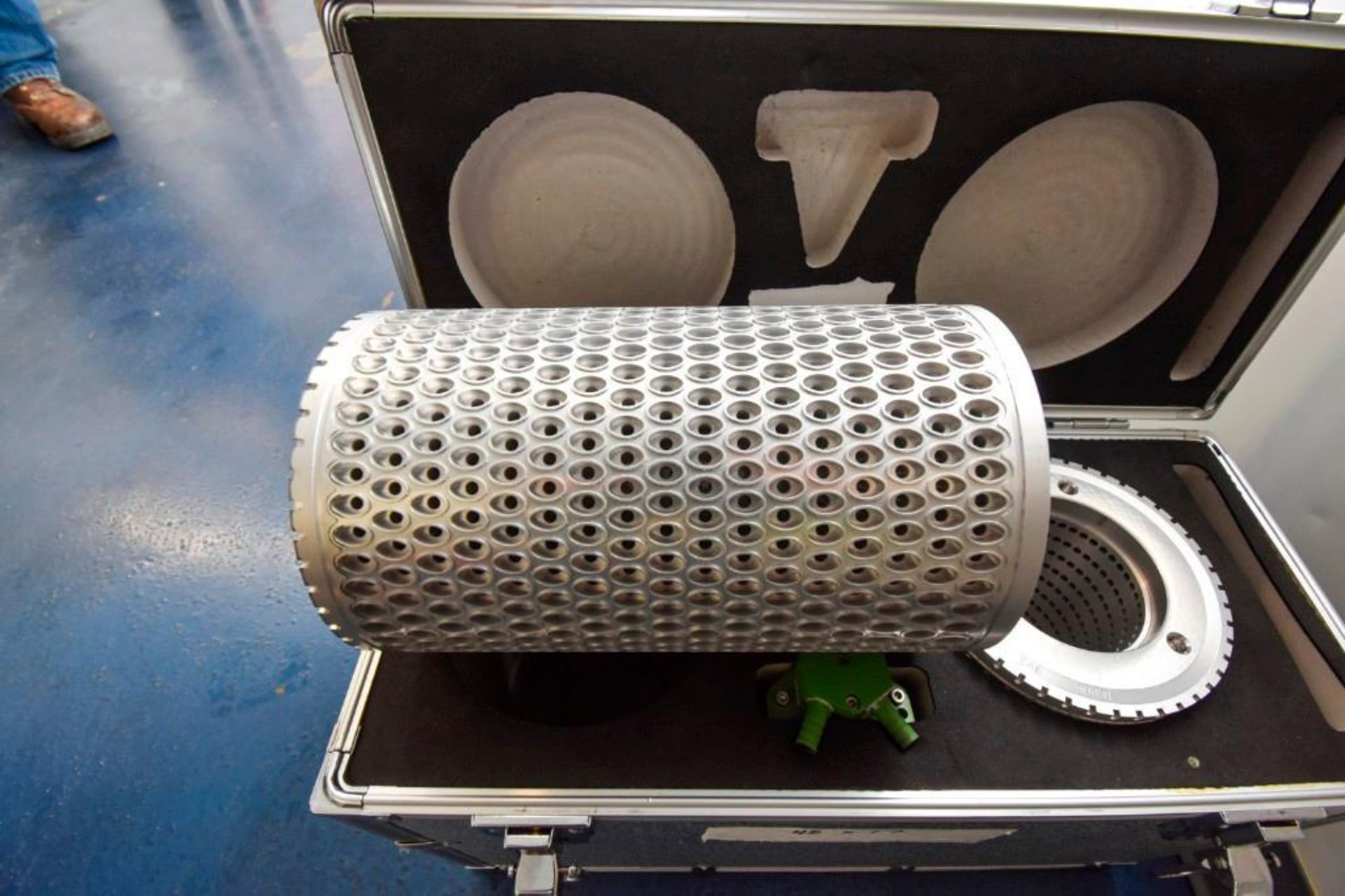

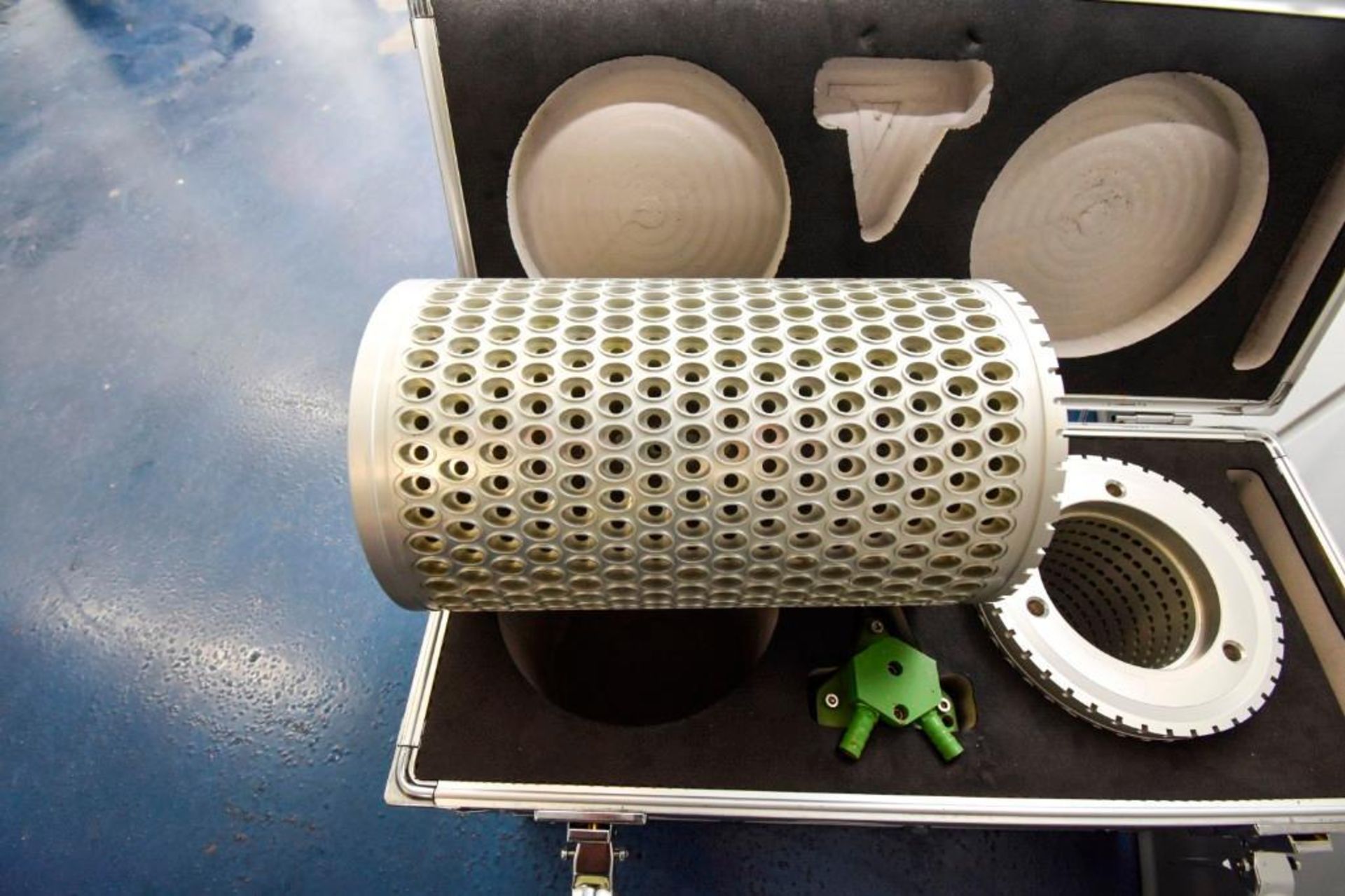

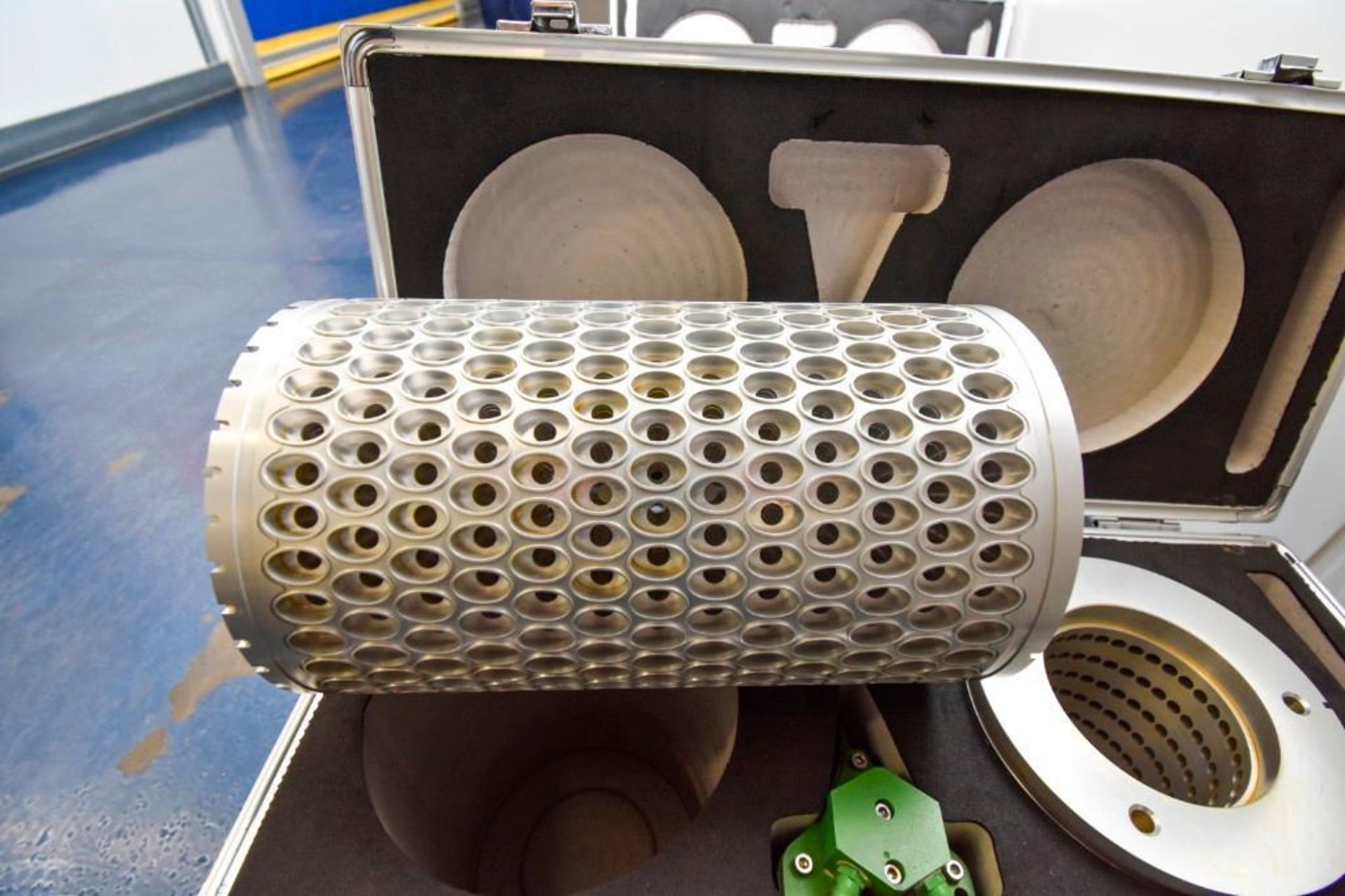

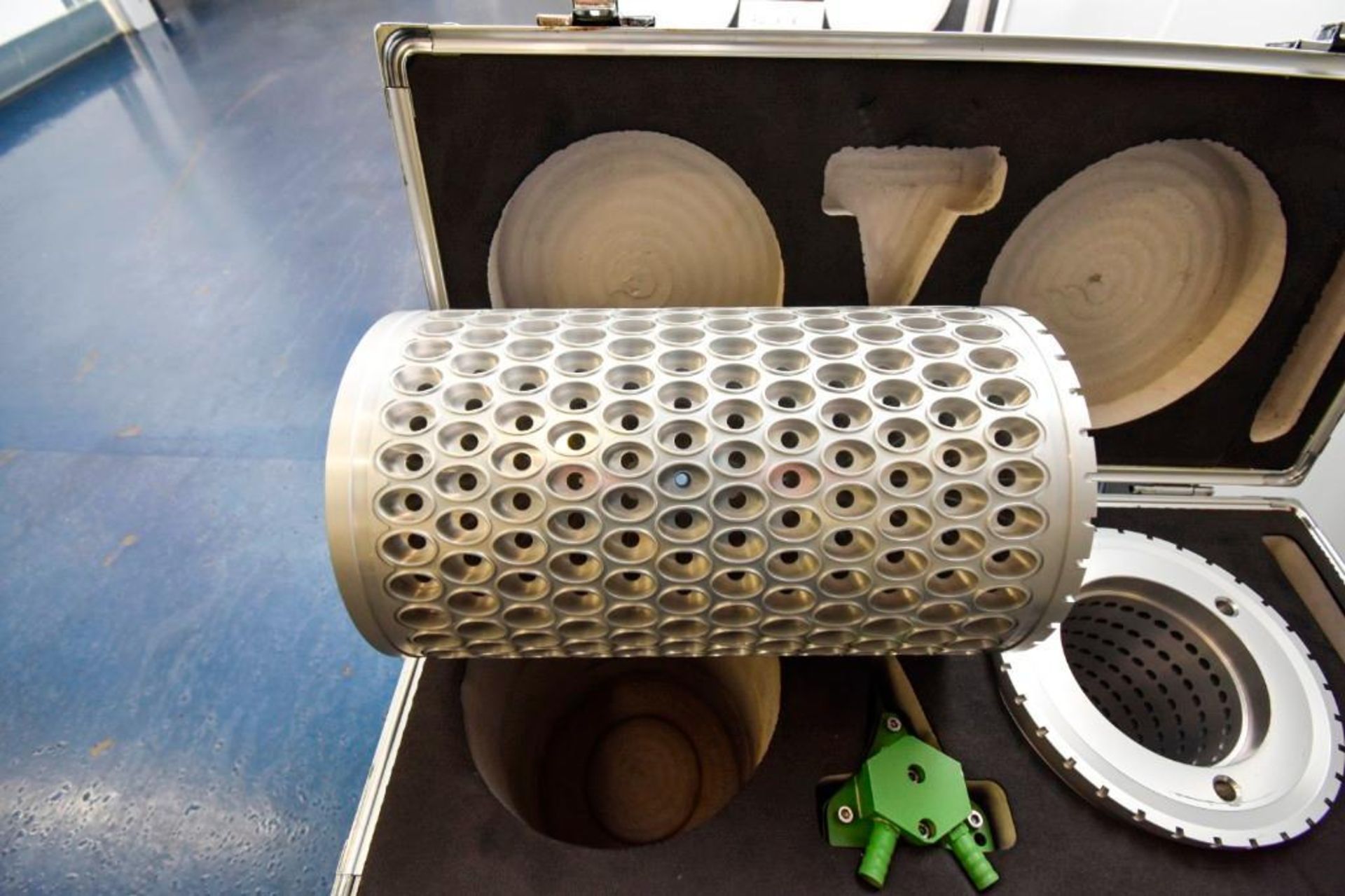

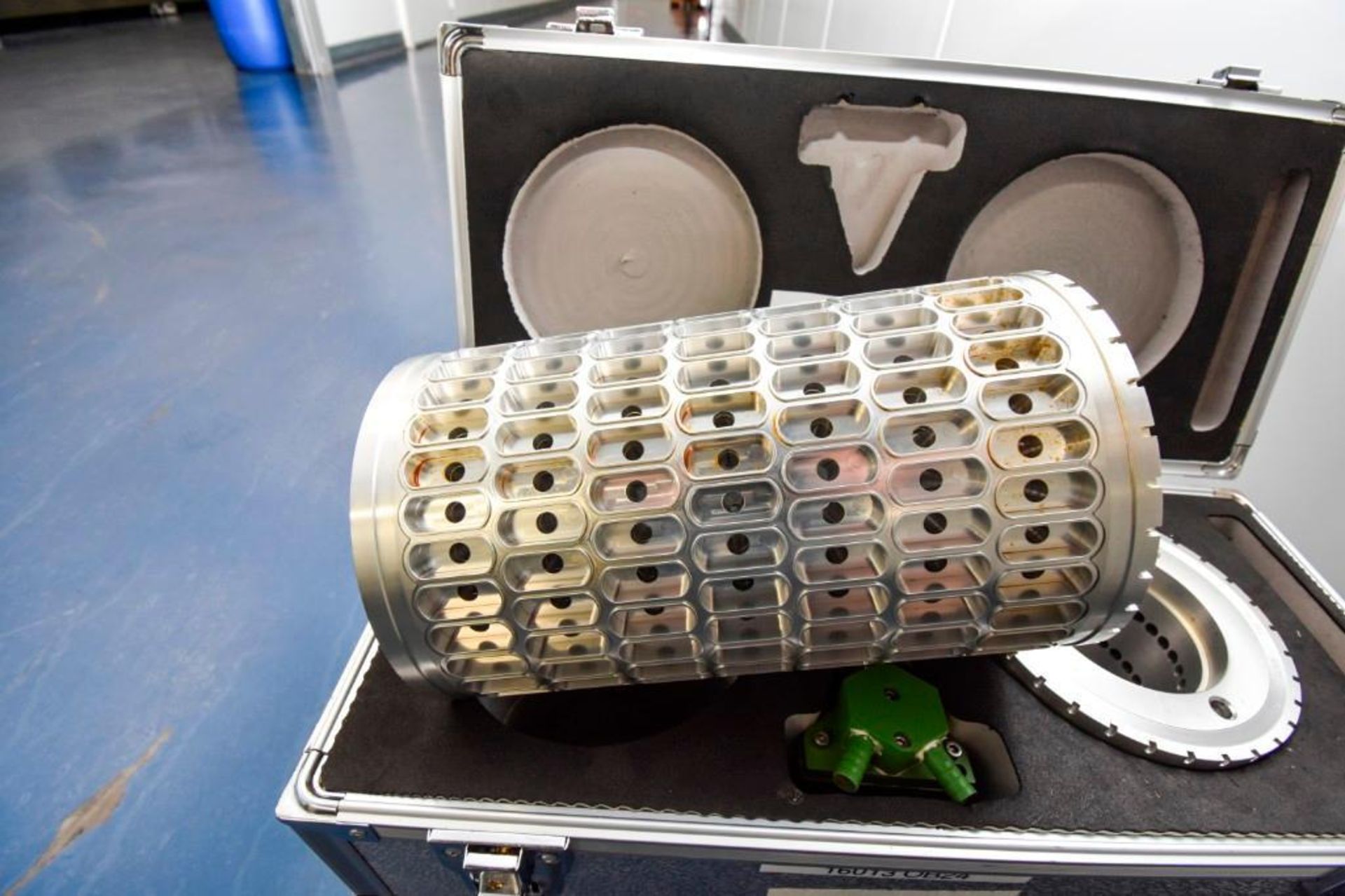

1. Rolling mold size (mm): Φ150×250

2. Number of mold cavities (8#OV): 504 pieces

3. Rolling mold speed: 0~8 rpm (servo drive, infinitely variable speed)

4. Single plunger Feed volume: 0~2 ml (continuously adjustable)

5. Number of plungers: 20

6. Loading accuracy: ±0.5%

7. Output (8#OV): 205,800 capsules/hour (roller mold speed 7 rpm/ minutes)

(20# OB): 102,900 grains/hour (roller mold speed 7 rpm)

8. Machine power: 12 kilowatts

9. Machine weight: 1500 kg

10. Overall dimensions (length × width × height, mm): 2200 × 1000 × 1900

Equipment technical characteristics:

1. Using advanced servo motor control technology, the operating speed of the main machine is increased to 8 rpm, while the transmission and vibration are greatly reduced.

2. The left and right spindle molds are designed to require no alignment. If adjustments are needed, they can be easily aligned through the touch screen.

3. The feeding pump uses electronic gears to realize automatic synchronous operation with the mold spindle. When replacing the mold, it is no longer like replacing the mold gear of the old-fashioned soft capsule machine.

4. The injection time can be automatically adjusted online via the touch screen, greatly saving manpower and time. The amount of injection can be adjusted online through the touch screen.

5. The program is designed with a recipe storage function, and the working data required for different products can be accessed and recalled as needed.

6. The left and right spindle holes are processed by boring machines imported from Switzerland, so that the runout and parallelism of the left and right spindles reach the world-class level.

7. The rubber lubrication adopts micro-quantity lubrication technology, making the soft capsule free of cleaning.

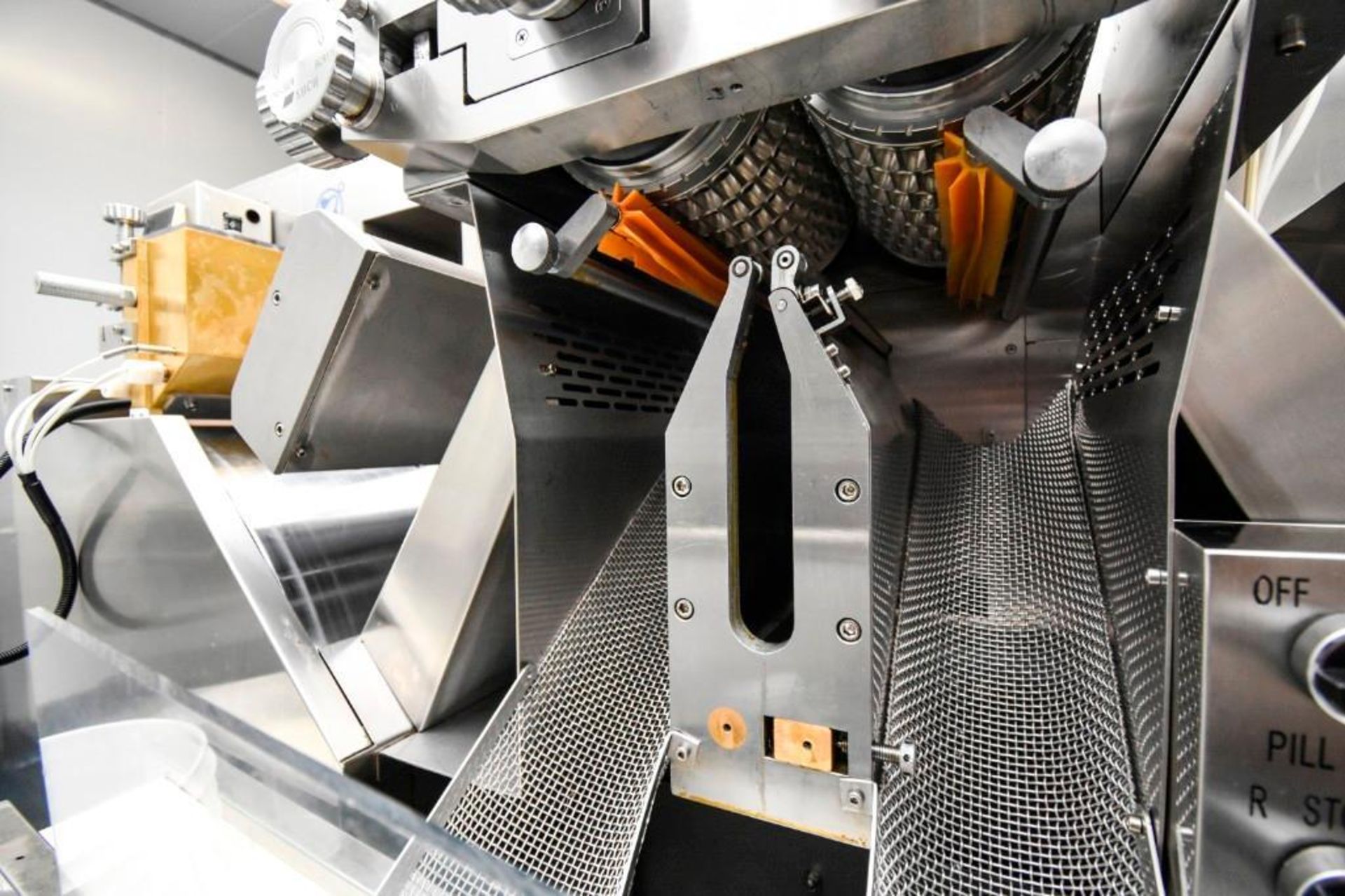

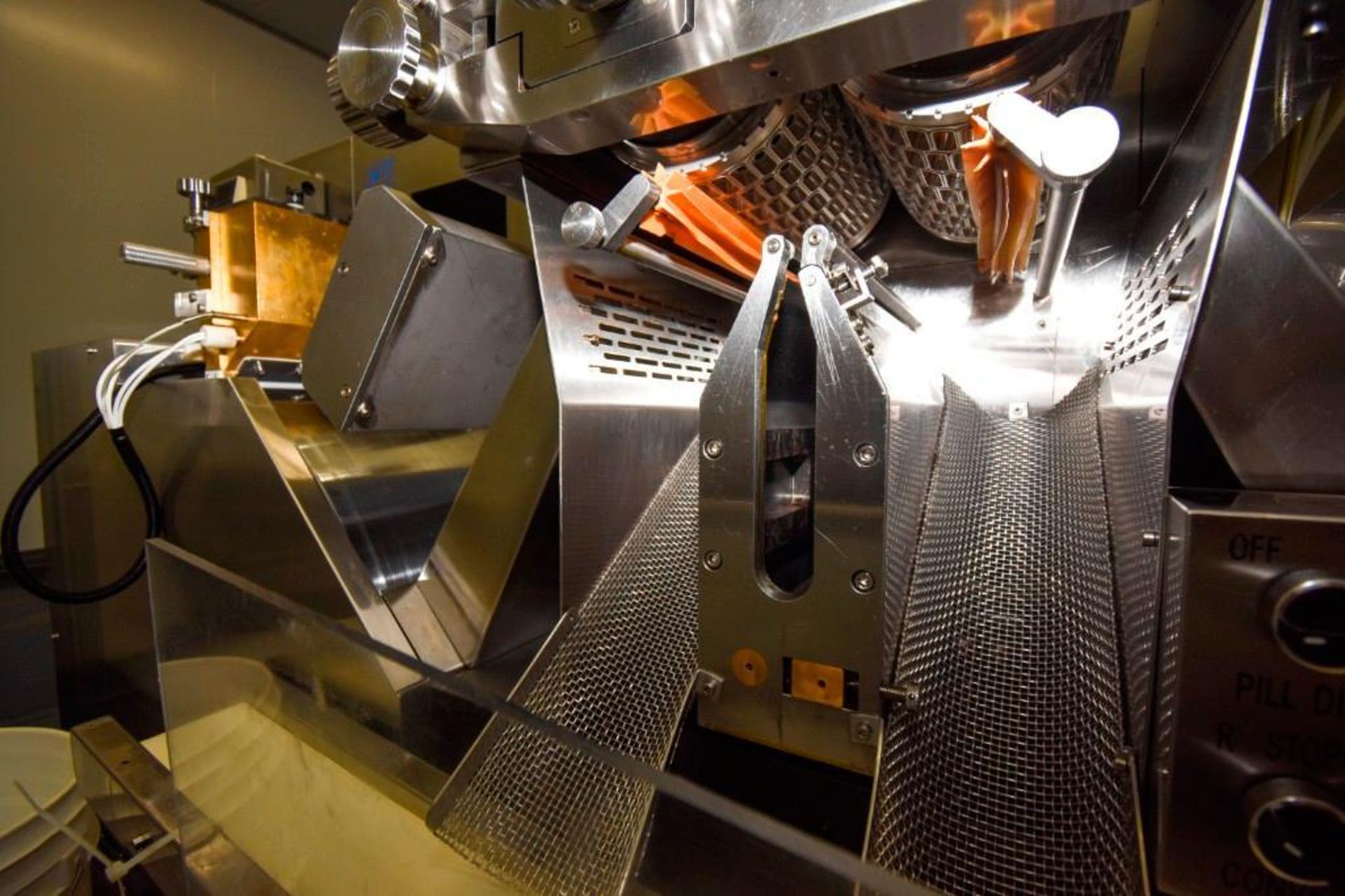

8. The forced cold air design on both sides of the capsule discharge area prevents the mesh glue from wrapping around the pill release device.

9. The pneumatic clamping system is used to make the pill pressing operation simple and reliable.

10. The electric lifting spray body can be parked at any position as needed to reduce the labor intensity of workers.

11. Due to the synchronous design of the servo system, the overall noise of the equipment is greatly reduced.

12. The gelatin box adopts a sleeve valve to realize automatic glue supply, and the glue clogging phenomenon of the gelatin box is completely eliminated.

13. The rubber is cooled by air-cooling and water-cooling to avoid condensation on the rubber rolling under high temperature and high humidity, which will affect the formation of the soft capsule.

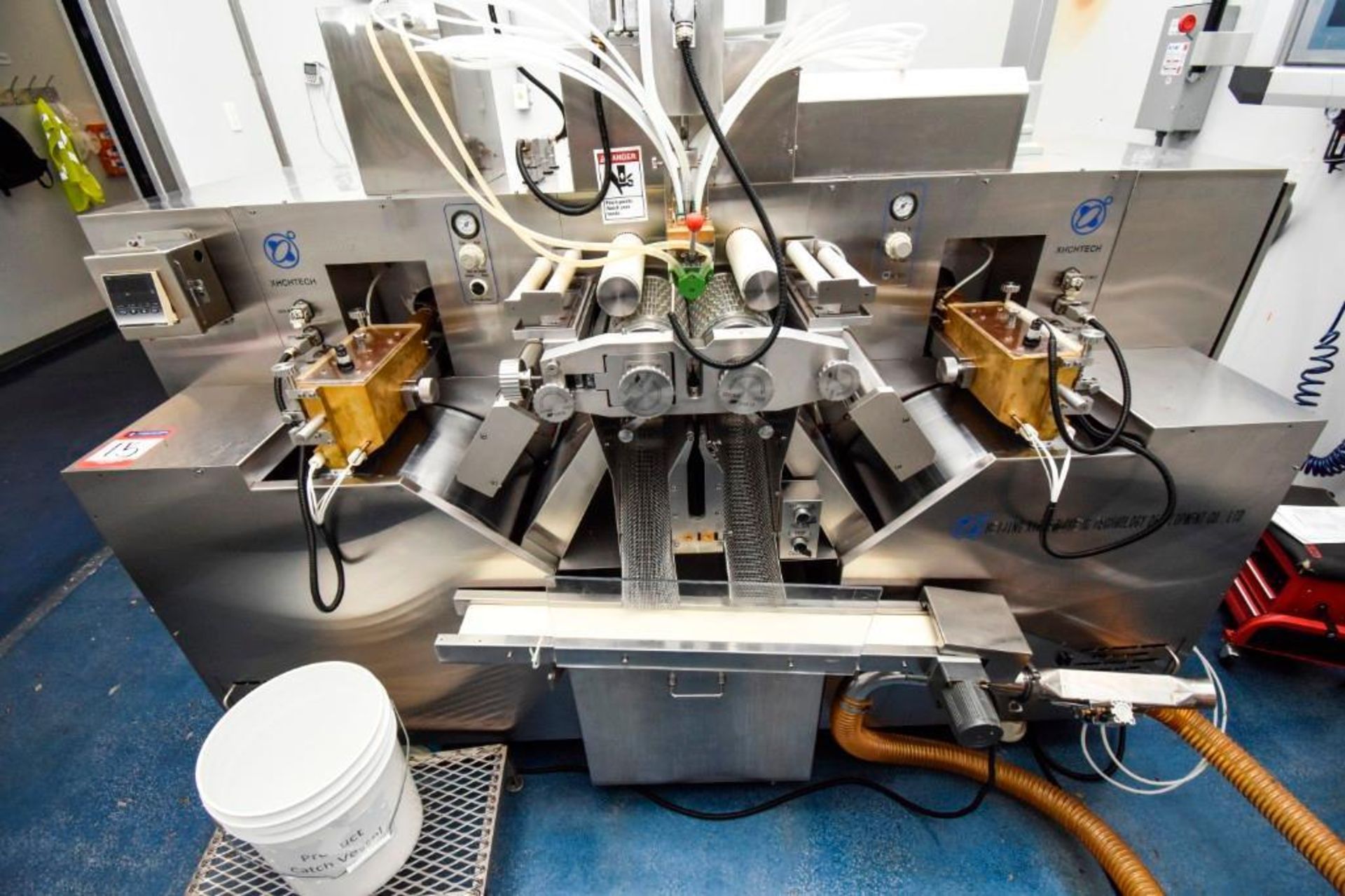

14. The electronic control system uses German Siemens PLC and touch screen, all frequency converters are from German Siemens, all relays are from French Schneider, and all connectors are from Italian Widmuller, making the electronic control system more stable and durable.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Fortworth, Texas

Skidding:$650

Loadout:$620

1- YWJ250-IIIA Fully Automatic High-Speed Softgel Capsule Machine

YWJ250-IIIA fully automatic high-speed soft capsule machine is a new generation of soft capsule production equipment developed by our company based on our company's many years of experience in soft capsule technology. This equipment is technologically advanced, has a simple and beautiful appearance, and is technically stable.

Equipment technical parameters:

1. Rolling mold size (mm): Φ150×250

2. Number of mold cavities (8#OV): 504 pieces

3. Rolling mold speed: 0~8 rpm (servo drive, infinitely variable speed)

4. Single plunger Feed volume: 0~2 ml (continuously adjustable)

5. Number of plungers: 20

6. Loading accuracy: ±0.5%

7. Output (8#OV): 205,800 capsules/hour (roller mold speed 7 rpm/ minutes)

(20# OB): 102,900 grains/hour (roller mold speed 7 rpm)

8. Machine power: 12 kilowatts

9. Machine weight: 1500 kg

10. Overall dimensions (length × width × height, mm): 2200 × 1000 × 1900

Equipment technical characteristics:

1. Using advanced servo motor control technology, the operating speed of the main machine is increased to 8 rpm, while the transmission and vibration are greatly reduced.

2. The left and right spindle molds are designed to require no alignment. If adjustments are needed, they can be easily aligned through the touch screen.

3. The feeding pump uses electronic gears to realize automatic synchronous operation with the mold spindle. When replacing the mold, it is no longer like replacing the mold gear of the old-fashioned soft capsule machine.

4. The injection time can be automatically adjusted online via the touch screen, greatly saving manpower and time. The amount of injection can be adjusted online through the touch screen.

5. The program is designed with a recipe storage function, and the working data required for different products can be accessed and recalled as needed.

6. The left and right spindle holes are processed by boring machines imported from Switzerland, so that the runout and parallelism of the left and right spindles reach the world-class level.

7. The rubber lubrication adopts micro-quantity lubrication technology, making the soft capsule free of cleaning.

8. The forced cold air design on both sides of the capsule discharge area prevents the mesh glue from wrapping around the pill release device.

9. The pneumatic clamping system is used to make the pill pressing operation simple and reliable.

10. The electric lifting spray body can be parked at any position as needed to reduce the labor intensity of workers.

11. Due to the synchronous design of the servo system, the overall noise of the equipment is greatly reduced.

12. The gelatin box adopts a sleeve valve to realize automatic glue supply, and the glue clogging phenomenon of the gelatin box is completely eliminated.

13. The rubber is cooled by air-cooling and water-cooling to avoid condensation on the rubber rolling under high temperature and high humidity, which will affect the formation of the soft capsule.

14. The electronic control system uses German Siemens PLC and touch screen, all frequency converters are from German Siemens, all relays are from French Schneider, and all connectors are from Italian Widmuller, making the electronic control system more stable and durable.

Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates for your convenience.

Location: Fortworth, Texas

Skidding:$650

Loadout:$620

Nutra Equipment - TX/FL

Endet ab

Generelle Versandinformationen vom Auktionshaus verfügbar

Skidding and Load out charges:

There will be loading and skidding charges added to your purchase at market rates for your convenience.

Wichtige Informationen

AUCTION DATE: Lots start closing 4/16/24 10 am PST

LOCATION: Multiple Locations, Texas

INSPECTION: Please contact us to schedule. 818-495-3038

PICKUP/REMOVAL: Final Loadout is May 9th, 2023.

18% Buyers Premium applies on all online purchases.

BidSpotter Customer Service Support Department

Have a question pertaining to the bidding process?

Visit our Frequently Asked Questions!

You can also start a live chat with a Bidspotter Support Representative by selecting Live Chat at the top of Bidspotter.com. More information on our chat system can be found by clicking here.

Customer Support Hours:

- Monday – Friday, 8:00 AM EST – 8:00 PM EST

Email: support@bidspotter.com

Office: (253) 858-6777 Toll Free: (866) 597-2437

AGB

Terms of Sale Agreement:

SELLER RESERVES THE RIGHT TO ACCEPT OR REJECT ANY AND ALL BIDS

- Only Credit Card, Wire Transfers or Cashier’s Checks payable to Chris Hillseth Enterprises (“CHE”) will be accepted for payment. No equipment will be removed from the sale site until payment is received by CHE. NO EXCEPTIONS! NO PAYMENT TAKEN ON SITE.

- CHE makes reasonable efforts to ensure that descriptions and other information are accurate. Bidders are strongly encouraged to verify any specifications and other information about equipment through consultation with independent experts or inspection by a qualified person. Any measurements provided, including shipping dimensions and weights, are approximate and/or estimated. Neither CHE nor the equipment owners make any warranties or guarantees. Under no circumstances will CHE or the seller be held responsible for any errors, omissions, discrepancies or inaccuracies. Everything is sold on an “AS IS/WHERE IS” basis with no warranties or representations whatsoever, either express or implied. WITHOUT LIMITING THE GENERALITY OF THE ABOVE, ANY AND ALL WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY OF GOODS ARE EXPRESSLY DISCLAIMED.

- For bidding approval, at its discretion, CHE may contact Bidders via email or telephone before to provide a deposit. Require a deposit of up to $10,000.00 USD (refundable without purchase) for lack of sufficient Bidspotter history e.g. first time Bidspotter registrant or negative Bidspotter history. Bidder will be notified if it is determined a deposit must be made. If CHE does not receive a response from its attempts to contact Buyer or if the Buyer does not provide a deposit, CHE reserves the right to refuse or cancel Buyer’s bids and re-sell Goods.

- Some items may have minimums or reserves. Therefore, bidder acknowledges they have been informed that Auctioneer may bid at the auction for its own account or on behalf of a third party or the seller.

- Purchaser hereby agrees to defend, indemnify and hold harmless auctioneer, Seller and their respective directors, officers, employees and other agents and representatives from and against any and all liabilities, judgments, claims, settlements, losses, damages, penalties, obligations and expenses, including attorney`s fees and expenses and other professional fees and expenses, incurred or suffered by such person arising from, by reason of, or in connection with any loss, damage or injury to person or property arising from, by reason of or in connection with the Goods sold hereunder. This indemnification shall survive delivery of the Goods to Purchaser and any subsequent sale or other transfer of the Goods to a third party.

- It is the buyers’ responsibility to secure all safety equipment to meet all applicable government safety standards in using or removing items purchased.

- Sales Tax will be added to the purchase of all taxable items. Dealers who purchase for resale must file their resale permit numbers. If sales tax is not collected at the time of sale and is deemed “needed to be paid” at a later date, buyer agrees to pay all required taxes.

- Purchaser does hereby indemnify and hold harmless auctioneer and seller from any and all damages, claims or liabilities from injuries to persons or property of any type whatsoever caused during the sale or by the removal of items purchased.

- Auctioneer and Seller shall have no liability to the purchaser due to non-delivery of any item for any reason other than to return to the Purchaser the monies deposited for non-delivered items.

- In the event the purchaser fails to pay the whole of the purchase within the time set forth by the auctioneers and/or fails to comply with any of the conditions or terms of sale, the seller may retain and/or recover the deposit specified as liquidated damages and, in addition thereto, items that are not paid for can be resold at public or private sale without further notice. Any deficiency resulting from such resale shall be paid to the auctioneers by the defaulting purchaser together with all charges, fees, and expenses incurred by such resale and enforcement of the obligation hereunder.

- The Bidder becomes solely responsible for all items purchased by him immediately following his winning bid at the auction. Therefore, he is advised to further guard and insure his items at his own discretion.

- No item can, on any account, be removed before buyer receives payment in full. Removal shall be at the expense, risk and liability of the purchaser. Auctioneers shall not be responsible for items not removed within the time allowed. If equipment is not removed within specified removal time, purchaser shall be liable for any moving and storage costs incurred and, if not so removed, the items shall be deemed abandoned.

- If any shortage exists on estimated counts, an adjustment will be made if claims are made at time of removal. No adjustment will be allowed after items are removed from the premises.

- If any dispute arises between two or more bidders, the sellers’ agent may or may not put the lot up again at once, and resell.

- The sellers’ agent, when acting as agent only, is not responsible for acts of its principals.

- A 18% Buyers premium will be applied to all sales in Addition to Applicable Local and State Sales Tax.

- By accepting a sale listing catalog and signing this form the buyer agrees to these terms and any announced terms at the sale.

- You will receive notifications from us regarding your purchases.

- Seller reserves the right to accept or reject any and all bids.

- All purchases of “regulated machines” will be reported pursuant to applicable Federal Regulations.

- All Bills must be completed on Day of Sale unless arrangements are made with Auction House prior to bidding.

- Full Payment at Termination of Sale.

- A 3% fee will be applied to all CC orders.

- Skidding and Load out charges: There will be loading and skidding charges added to your purchase at market rates.

Inspection date (day only) is:

By Appointment Only. Call 818 495 3038 to Schedule.

Inspection locations:

Various Locations, call for specific item.

Inspection by appointment only.

Call or Email Logan Hillseth logan@chrishillsethenterprises.com or Patrick Hillseth at (818)495-3038 patrick@chrishillsethenterprises.com