20

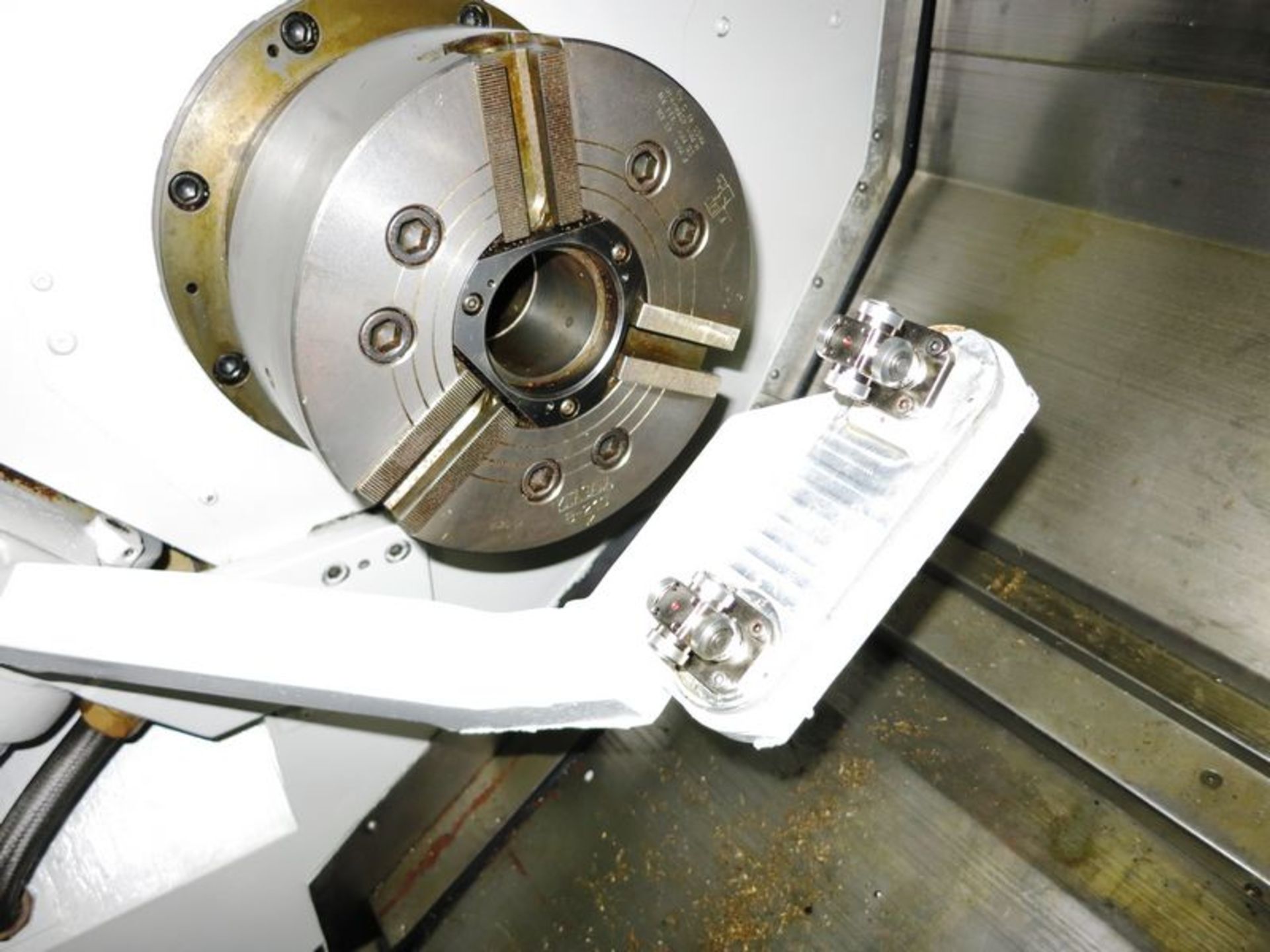

Mazak Integrex 200-3ST Multi-Axis CNC Turning & Milling Center, S/N 165243, New 2003 General

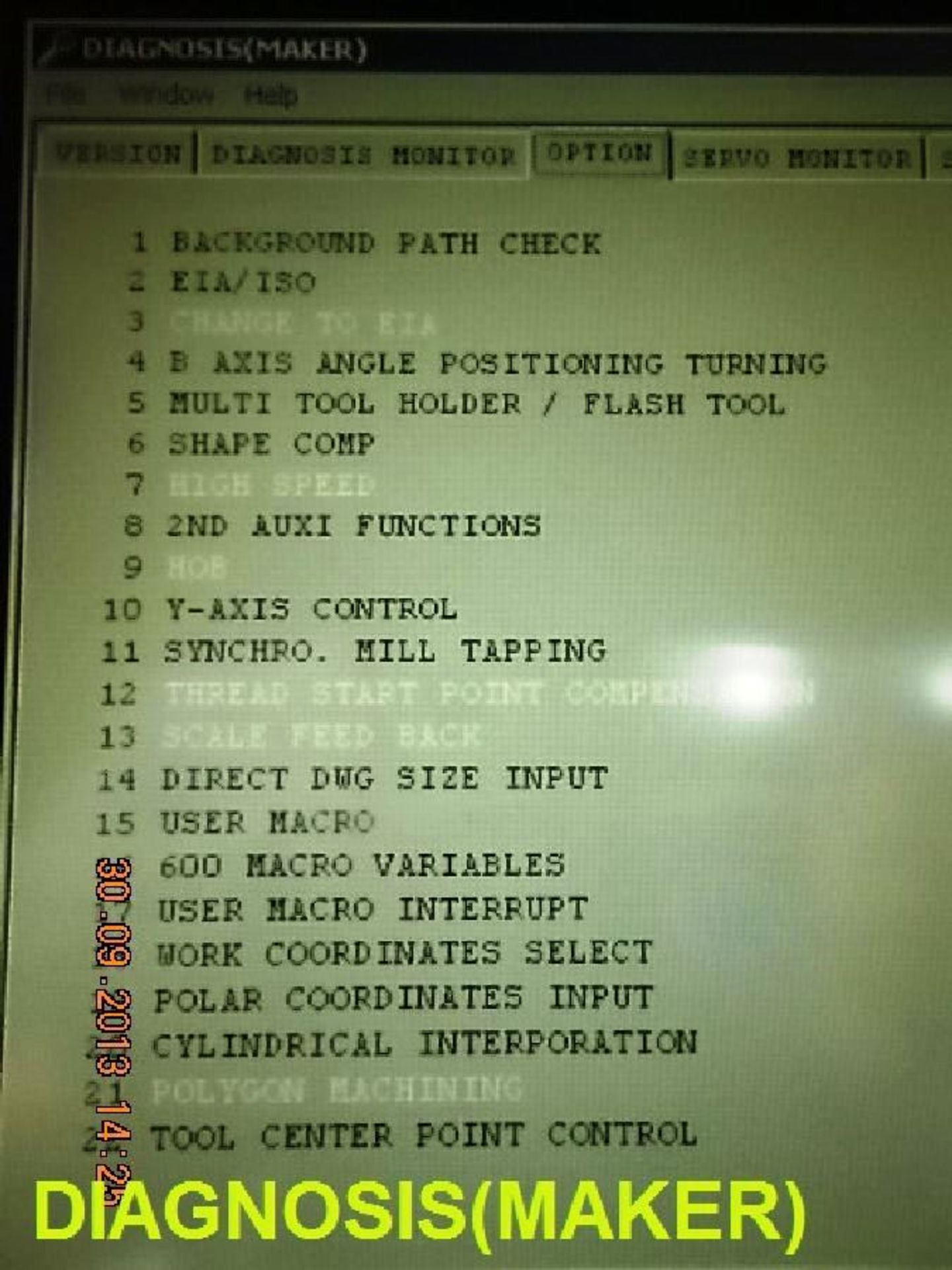

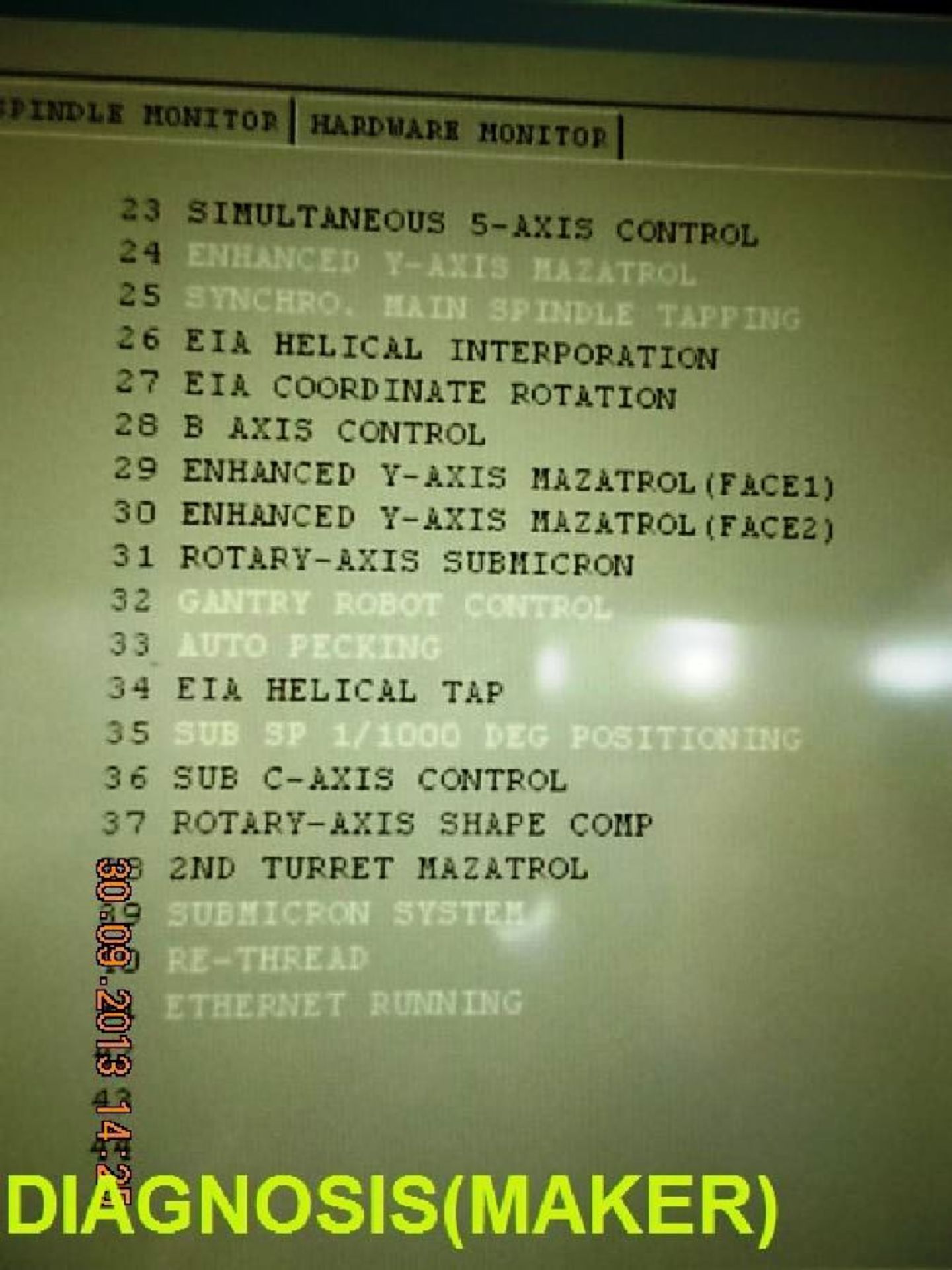

Mazak Integrex 200-3ST Multi-Axis CNC Turning & Milling Center, S/N 165243, New 2003 General Specifications, Max. swing 26", Max. swing over carriage 19.7" - 26", Note: Depends upon workpiece length, tool magazine, type and Y Axis position., Max. cutting diameter: Chucking 26", Max. cutting length 40", Max. distance between chuck faces 41.14", Main Spindle (L):, Spindle nose A2-6, Spindle bore 2.99", Max. bar work 2", Spindle speed/ranges 35-5000 RPM/2, Spindle index (programmable) 0.0001 degrees, Spindle horsepower (cont./30 min) 20/30 HP (A.C.0, Spindle torque 258.1 ft-lbs, Second Spindle (R):, Spindle nose A2-6, Spindle bore 2.99", Max. bar work 2"x34.6"deep from, chuck face, Spindle speed/ranges 35-5000 RPM/2, Spindle index (programmable) 0.001 degree, Spindle horsepower (cont./30 min) 20/25 HP (A.C.), Spindle torque 241 ft-lbs, Upper Turret and Tooling:, Type of turret 1 position,w/ATC, Magazine capacity 40 Tools, Tool selection method Random, Max. tool dia. w/all pockets full 3.54", Max. tool dia. w/adjacent pockets empty 4.92", Max. tool length (from gage-line) 11.8", Max. tool weight 22 lbs, Rotary tool spindle speed/ranges 12,000 RPM/1, Rotary tool spindle horsepower (20% ED) 20 HP (A.C.), Rotary tool torque (20% ED) 88.2 ft-lbs, 2, Stock 1, 2 2 3, SERIAL NUMBER 4 NEW 5, GENERAL SPECIFICATIONS: (Cont.), Lower Turret and Tooling:, Type of turret Drum, Tool shank height 1.0" x 1.0", Tool size (boring bar max. diameter) 1.25", Total number of tools 9, Tool selection method Bi-Directional, Tool Index time (1 ste) 0.14 Seconds, Axis Travels:, B-Axis (.0001 deg. increments) 225 Deg., Y-Axis +/- 3.15" X-Axis 22.83" Z-Axis 41.1" X2 Axis lower 5.9" Z2 Axis lower 38.98" Second headstock W-Axis 41.34" Axis Rapid Rates: Y-Axis 1023 IPM X/X2 Axis 1496 IPM Z/Z2 Axis 1496 IPM Second headstock W-Axis 1181 IPM C-Axis 400 RPM Machine weight (Approx) 22,440 Lbs., Equipped With, Mazatrol Fusion 640MT Pro CNC Control, Control Options:, Background Path Check EIA/ISO, B-Axis Angle Positioning Turning, Mullti ToolHolder/Flash Tool, Shape Comp, 2nd Auxi Functions, Y-Axis Control, Synchro Mill Tapping, Direct DWG Size Imput, EUIPPED WITH: (Cont.), Control Options: Cont., User Macro, 600 Macro Variables, User macro Interrupt, Work Coordinates Select, Polar Coordinates Input, Cylindrical Interporation, Tool Center Point Control, Simultaneous 5-Axis Control, EIA Helical Interporation & EIA Coordinate Rotation, B-Axis Control, Enhanced Y-Axis Mazatrol (Face 1 and Face 2), Rotary-Axis Submicron, EIA Helical Tap, Sub C-Axis Control, Rotary-Axis Control, Rotary-Axis Shape Comp & 2nd Turret Mazatrol, KM 63 Type tooling (Upper turret), Coolant through milling head (up-turret), 1 KG Flood Coolant (lower turret), 2nd Spindle C-Axis 0.0001 degree increment, 40 KM-Tool Magazine, B-Axis index 5 degree (coupling clamp), Chip Conveyor side disposal (hinge type) 40", Auto chuck Jaws open/close(1 & 2 Spindle), Operator door interlock with lock-switch, 10" Thru Hole chuck B-210, 8" Thru Hole Chuck B-208A615, 3.5" FDD Unit, Y-Axis Control, Hyd. Pressure Interlock, 213 PSI Thru/Flood coolant (upper turret)/71 PSI Lower, C-Axis 0.0001 deg.Incr.(1st spindle) B-Axis 0.0001 Deg. Incr N/A Contouring Lower 9 Position drum turret, Automatic tool eye Chuck Open/Close,

Mazak Integrex 200-3ST Multi-Axis CNC Turning & Milling Center, S/N 165243, New 2003 General Specifications, Max. swing 26", Max. swing over carriage 19.7" - 26", Note: Depends upon workpiece length, tool magazine, type and Y Axis position., Max. cutting diameter: Chucking 26", Max. cutting length 40", Max. distance between chuck faces 41.14", Main Spindle (L):, Spindle nose A2-6, Spindle bore 2.99", Max. bar work 2", Spindle speed/ranges 35-5000 RPM/2, Spindle index (programmable) 0.0001 degrees, Spindle horsepower (cont./30 min) 20/30 HP (A.C.0, Spindle torque 258.1 ft-lbs, Second Spindle (R):, Spindle nose A2-6, Spindle bore 2.99", Max. bar work 2"x34.6"deep from, chuck face, Spindle speed/ranges 35-5000 RPM/2, Spindle index (programmable) 0.001 degree, Spindle horsepower (cont./30 min) 20/25 HP (A.C.), Spindle torque 241 ft-lbs, Upper Turret and Tooling:, Type of turret 1 position,w/ATC, Magazine capacity 40 Tools, Tool selection method Random, Max. tool dia. w/all pockets full 3.54", Max. tool dia. w/adjacent pockets empty 4.92", Max. tool length (from gage-line) 11.8", Max. tool weight 22 lbs, Rotary tool spindle speed/ranges 12,000 RPM/1, Rotary tool spindle horsepower (20% ED) 20 HP (A.C.), Rotary tool torque (20% ED) 88.2 ft-lbs, 2, Stock 1, 2 2 3, SERIAL NUMBER 4 NEW 5, GENERAL SPECIFICATIONS: (Cont.), Lower Turret and Tooling:, Type of turret Drum, Tool shank height 1.0" x 1.0", Tool size (boring bar max. diameter) 1.25", Total number of tools 9, Tool selection method Bi-Directional, Tool Index time (1 ste) 0.14 Seconds, Axis Travels:, B-Axis (.0001 deg. increments) 225 Deg., Y-Axis +/- 3.15" X-Axis 22.83" Z-Axis 41.1" X2 Axis lower 5.9" Z2 Axis lower 38.98" Second headstock W-Axis 41.34" Axis Rapid Rates: Y-Axis 1023 IPM X/X2 Axis 1496 IPM Z/Z2 Axis 1496 IPM Second headstock W-Axis 1181 IPM C-Axis 400 RPM Machine weight (Approx) 22,440 Lbs., Equipped With, Mazatrol Fusion 640MT Pro CNC Control, Control Options:, Background Path Check EIA/ISO, B-Axis Angle Positioning Turning, Mullti ToolHolder/Flash Tool, Shape Comp, 2nd Auxi Functions, Y-Axis Control, Synchro Mill Tapping, Direct DWG Size Imput, EUIPPED WITH: (Cont.), Control Options: Cont., User Macro, 600 Macro Variables, User macro Interrupt, Work Coordinates Select, Polar Coordinates Input, Cylindrical Interporation, Tool Center Point Control, Simultaneous 5-Axis Control, EIA Helical Interporation & EIA Coordinate Rotation, B-Axis Control, Enhanced Y-Axis Mazatrol (Face 1 and Face 2), Rotary-Axis Submicron, EIA Helical Tap, Sub C-Axis Control, Rotary-Axis Control, Rotary-Axis Shape Comp & 2nd Turret Mazatrol, KM 63 Type tooling (Upper turret), Coolant through milling head (up-turret), 1 KG Flood Coolant (lower turret), 2nd Spindle C-Axis 0.0001 degree increment, 40 KM-Tool Magazine, B-Axis index 5 degree (coupling clamp), Chip Conveyor side disposal (hinge type) 40", Auto chuck Jaws open/close(1 & 2 Spindle), Operator door interlock with lock-switch, 10" Thru Hole chuck B-210, 8" Thru Hole Chuck B-208A615, 3.5" FDD Unit, Y-Axis Control, Hyd. Pressure Interlock, 213 PSI Thru/Flood coolant (upper turret)/71 PSI Lower, C-Axis 0.0001 deg.Incr.(1st spindle) B-Axis 0.0001 Deg. Incr N/A Contouring Lower 9 Position drum turret, Automatic tool eye Chuck Open/Close,

CNC Exchange – Consignment Online Sale - Over 50 CNC Machines

Ends from

Venue Address

For Premier Asset Recovery Group delivery information please telephone 312-280-1234.

Important Information

Over 50 Fantastic CNC Machines and More! Machining Centers, Swiss Type Sliding Headstock, Drill Tap Centers, (Call Now To List your Machines)

BidSpotter Customer Service Support Department

To reach a member of our qualified support staff regarding information or questions pertaining to the bidding process; please reach us by phone or email.

- Available Monday – Friday, 8:00am – 12:00am ET.

- Email: Support@bidspotter.com

- Office: 253-858-6777

- Frequently Asked Questions

Terms and Conditions

1. IDENTIFICATION: All Participants are required to register prior to becoming an Approved Bidder. All Participants are required to give full name, permanent street address, phone numbers, email address, valid credit card and business name. Subsequent to registration on BidSpotter, approval to bid is at our discretion.

2. PAYMENT: Invoices must be paid in full by Monday, February 13, 2017. Payment may be made by wire transfer, company check with a bank letter of guarantee, certified funds or cash. A BUYERS PREMIUM OF 18% WILL BE APPLIED TO INVOICE IN ADDITION TO THE SALES PRICE.

Where required by law, ANY APPLICABLE SALES TAX WILL BE APPLIED TO ALL SALES UNLESS BUYER HAS A PROPER EXEMTION. NO MERCHANDISE WILL BE RELEASED UNITIL INVOICE IS PAID IN FULL.

3. Purchase of any lot is at the Purchaser's risk with risk of loss immediately passing to Purchaser upon the auctioneer's call. Neither Premier Asset Recovery Group, LLC, nor its consignors, have any liability of any nature whatsoever to Purchaser if the lot is not delivered to Purchaser due to fire, theft, damage, or any other cause.

4. REMOVAL: All purchases MUST be removed as herein listed. Small items (Tooling, Machine Parts & Accessories, etc.) are to be REMOVED WITHIN 2 DAYS OF THE AUCTION. WE ASSUME NO RESPONSIBILITY FOR SMALL, CARRIABLE ITEMS LEFT ON PREMISES ONE DAY AFTER SALE. All other Machinery & Equipment must be removed by Friday, February 24, 2017.

5. Purchases may be removed only on presentation of paid bill. Removal shall be at the expense, risk and liability of the purchaser. Auctioneer shall not be responsible for goods not removed within the time allowed.

6. CONDITION: All Items are sold on “as is – where is”, “in place”, “with all faults” basis no conditions or warranties or representation, written or oral, is given with any lot. All statements contained in Premier Asset Recovery, LLC catalog, website, and marketing material or by the auctioneers, or in any bill of sale, invoice or elsewhere as to description, size, quantity, quality, capacity, model, serial number, measurements or condition, are approximated statements and shall not be deemed to be representations or warranties, oral or written, with respect to any lot. No sale is invalid or made void by reason of any flaw in a lot or by reason of a lot being incorrectly described. Description and Photos are not guaranteed. Make yourself available e for the Inspection period. It is the buyer’s responsibility to inspect before biding. Premier Asset Recovery Group assumes no liability for error or omissions associated with the auction sale. The buyer does hereby assume and does agree to indemnify and hold the auctioneer and seller harmless from any future claim which shall pertain the fitness or use of the assets being purchased.

7. CLAIMS: NO CLAIMS WILL BE ALLOWED AFTER REMOVAL OF GOODS FROM PREMISES OR LEFT ON PREMISES PAST ALLOWED TIME LIMIT.

8. RESPONSIBILITY FOR NON-DELIVERY: Neither the auctioneer nor the seller, in any event, shall be liable for non-delivery or for any other matter or thing, to any purchaser of any lot, other than for the return to the purchaser of the deposit or sum paid on said lot, should the purchaser be entitled hereto.

9. COMPLIANCE WITH TERMS OF SALE: In default of payment of bills in full within the time therein specified, the auctioneer in addition to all other remedies allowed by law, may retain all monies received as deposit or otherwise, as liquidated damages. Lots not paid for and removed within the time allowed herein may be resold at public or private sale without further notice, and any deficiency, together with all expenses and charges of resale including legal fees, will be charged to the defaulting purchaser.

10. RISK TO PERSON AND PROPERTY: Persons attending during exhibition, sale or removal of goods assume all risks of damage of or loss to person and property and specifically release the auctioneer and seller from liability therefore. Neither the auctioneer nor his principal shall be liable by reason of any defect in or condition of the premises on which the sale is held.

11. CONTRACT MOVERS: If purchaser wishes to hire or contract with a machinery mover, rigger or other type of outside contractor, PROPER INSURANCE protecting Premier Asset Recovery Group, LLC and the people or company that the auctioneers are conducting the sale for against any or all claims arising from personal injury and/or property damage created by their actions. This requirement is for the auctioneer`s protection - NOT FOR THE PURCHASER`S therefore the auctioneer suggests that the purchaser review the insurance policies of the machinery mover regarding the coverage that they have protecting the purchaser and damage or loss of the equipment they may be moving for the purchaser.

12. ADDITION TO OR WITHDRAWAL FROM SALE: The auctioneer reserves the right to withdraw from sale any of the property listed or to sell at this sale property not listed, and also reserves the right to group one or more lots into one or more selling lots or to subdivide into two or more selling lots. Whenever the best interest of the seller will be served, the auctioneer reserves the right to sell all the property listed, in bulk.

13. It is the Purchaser’s sole responsibility to meet all governmental safety and environmental standards in removing, shipping and using purchased items. Certain of the items for sale may contain “hazardous substances”, as that term is defined under federal, state or local environmental laws and regulations. Premier has no duty to remove any hazardous substances that are contained in or are a part of any items. Purchasers agree to defend (by counsel satisfactory to Premier) and indemnify Premier and hold Premier harmless from any against any claim. Demand, cause of action, liability or expense (including attorney’s fees and costs) asserted against or incurred by Premier in connection with the sale, removal, shipment, or use of any purchased items.

14. DISPUTE BETWEEN BIDDERS: The auctioneer`s decision will be final and absolute.

15. RECORDS: The record of sale kept by the auctioneer and bookkeeper will be taken as final in the event of any dispute.

16. INDEPENDENT CONTRACTOR: The auctioneer is acting as an independent contractor only and is not responsible for the acts of its principals or sellers.

17. ADDITIONAL TERMS AND CONDITIONS: The auctioneer may add other terms and conditions of sale, such additional terms and conditions to be announced prior to the auction.

18. RESERVE: The auctioneer reserves the right to reject any and all bids. On lots upon which there is a reserve, the auctioneer or his assigned agents, shall have the right to bid on behalf of the seller.

19 These terms and conditions, and all questions with respect to the interpretation of these Terms and Conditions, shall be governed by and construed in accordance with the internal law of the State of Illinois, without regard to conflict of law’s provisions. All bidders expressly consent to personal and exclusive jurisdiction in the courts of the State of Illinois located in Cook County.